The T-34 was a mystery for the USSR’s allies for most of WWII. A sample of the legendary tank was only sent abroad in 1943, but information about an improved variant with a 3-man turret and an 85 mm gun became available soon after. Very little was known about this tank up until the spring of 1945, and with the end of the war the remote possibility of getting a sample vanished altogether. However, the odds of seeing this tank again increased with time. The Korean War broke out on June 25th, 1950. The Korean People’s Army (KPA) received aid from the USSR, which included T-34-85 tanks.

Old tanks in a new war

According to American sources, the North Koreans crossed the border on June 25th, 1950, with one armoured division consisting of three regiments numbering 160 T-34-85 tanks in total. The 16th and 17th Armoured Brigades joined them by September, and in November the 17th Mechanized Division with 41 tanks and 41st, 45th, and 46th Tank Regiments with 10 tanks each and the 43rd Mechanized Regiment with 13 tanks also crossed the border. According to the Americans, the North Koreans initially built up a force of 320 tanks in total, which was later reinforced by another 250 tanks.

The T-34-85 was far from the most advanced tank in the world at the time, but the North Koreans were lucky. The most powerful American tank available in theatre was the M24 Chaffee. According to the authors of the Operations Research Office report on the employment of tanks in Korea, the North Korean forces successfully mitigated the drawbacks imposed by the terrain of the country and used their tanks effectively.

American Chaffee tanks, transferred to Korea from Japan, had to fill in for medium tanks, which was not a role that they played well. 75 mm rounds bounced off the T-34-85’s armour, and its 85 mm gun could destroy the Chaffee from a long range. The impact that these first engagements had on American soldiers can be seen in a report written by one of the most famous figures in American tank building, Gladeon Barnes. The report dated June 12th, 1951, was dedicated to the engineering experience gathered during the Second World War, but Barnes considered it necessary to mention the heavy losses that the American light tanks took in Korea in battle with the “heavy T-34 Russian tank”. Even small groups of North Korean tanks were enough to rout defending infantry, and only the arrival of Super Bazooka anti-tank rocket launchers and domination of the skies by American aircraft dulled the spearhead of the offensive.

North Korean tank forces surpassed those of the defenders in both quality and quantity until August of 1950, when the T-34-85’s equals, the M4A3E8 Shermans, arrived on the scene along with more serious opponents: the M26 Pershing, which was reclassified as a medium tank by this time, and its descendants, the M45 and M46 Patton tanks. The American forces received 1231 tanks in total.

The application of heavier tanks, well trained troops, and tight cooperation with infantry gave immediate results. The Americans stated that the T-34-85 never appeared in a group larger than 10-12 tanks and chiefly fought in 2-3 tank squads. The already humble North Korean tank force began to shrink rapidly and nearly ceased to exist by the time the KPA retreated to the 38th parallel.

Afterwards, American tanks were chiefly lost for technical reasons, and even if they were lost to enemy action, then it was usually due to hitting mines. Nevertheless, T-34-85 tanks managed to knock out not only Shermans, but even Pershings and Pattons in battle. American total losses between June 1950 and January 1951, including breakdowns, added up to 256 tanks. To compare, the KPA left 239 T-34-85s and 74 SU-76es behind during their retreat.

American claims of North Korean tank kills were much higher. Ground forces claimed 143 tanks knocked out, the Navy claimed 433, and the Air Force reported 2554 kills! The total claims surpassed the number of tanks actually available by a factor of nearly 10.

The explanation is simple. American pilots often fired on knocked out or abandoned tanks. It was nearly impossible to calculate how many T-34-85 tanks were lost to breakdowns, as any immobile tank would be turned into Swiss cheese from the air long before it could be examined by ground forces. Nevertheless, inspection teams managed to estimate how North Korean vehicles were lost.

Generally, they were destroyed from the air. 60 tanks were destroyed by napalm, 17 tanks with rockets, 7 by bombs, and 7 by cannon or machine gun fire. A T-34-85 tank destroyed by an AT-6 trainer aircraft is listed separately. In total, 102 tanks were knocked out by aircraft (42%). Fewer were destroyed from land: 39 of them were destroyed by American tanks, 13 with Bazookas, 5 with artillery: 57 tanks (24%) in total. One North Korean tank was disabled by mines, 5 were abandoned due to breakdowns, 15 tanks were abandoned for an unnamed reason, and 59 tanks (25% of the total) had absolutely no damage at all, and it was hard to determine why they were abandoned by crews.

Prisoners of war reported that napalm was a particularly lethal anti-tank weapon. The crew was only harmed on a direct hit, but even a close miss could ignite the tank’s road wheel tires, after which the crew typically abandoned the tank. The fire would then slowly reach either the ammunition or the fuel tank, which would then lead to a complete loss of the tank.

The Americans opened fire from up to 2000 yards (1830 meters) when fighting the T-34-85, although the typical engagement range was less than 650 yards (600 meters). American crews considered their tanks superior to the T-34-85s, counting the M4A3E8 less effective than the Pershings or Pattons, which had tougher armour and more powerful guns.

Cross-examination

The Americans received a large amount of information about North Korean tank forces from prisoners of war. 9 out of 24 officers who were interrogated turned out to be tankers, a larger proportion than any other type of forces. These men included both commanders trained by Soviet advisors and reinforcements trained in Pyongyang after the war began.

Prisoners stated that losses from American aircraft were high indeed. An officer from the 105th Armoured Division also described widespread damage from mines, although the damage was never major and never resulted in an irrecoverable loss. As the Americans suspected, many tanks were lost due to being driven at night on bad roads by inexperienced drivers. If this tank became stuck it would be impossible to recover due to a lack of engineering vehicles. A bogged down T-34-85 became an easy target for American pilots during the day. Tanks also often had to be abandoned due to a lack of fuel or spare parts. Only one POW reported that his tank was blown up by the crew when it became bogged down.

POWs did not distinguish between fire from tanks and towed guns. They reported that the tank crew usually took heavy casualties if the armour was penetrated. Tank crews usually managed to leave their tanks successfully if they were set aflame by napalm from the air, or in some cases leaving as soon as American aircraft were seen. Losses among North Korean tankers were high. The POWs estimated them at around 50-60%.

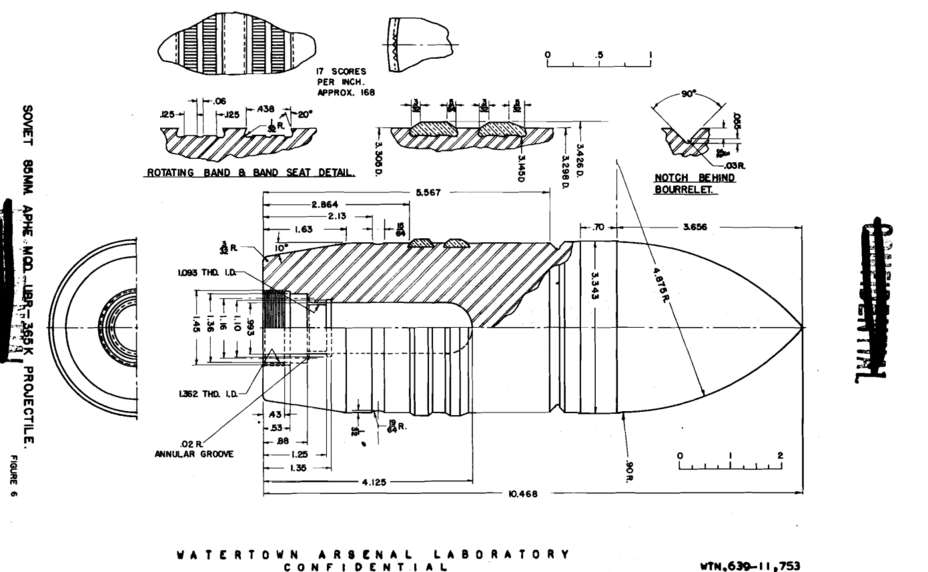

The stock ammunition loadout consisted of 55 rounds: 30 anti-personnel, 20 HE, and only 5 AP, which explains the low losses taken by American in tank duels. All POWs reported this proportion of ammunition issued. The tanks also carried 2000 rounds of ammunition for the machine guns and 25 grenades. POWs usually reported firing at infantry using the coaxial machine gun, the hull machine gun was rarely used.

The KPA tankers recalled that they began the campaign in high spirits. Marches were done without any attempts at concealment. Some POWs reported that they were so sure about their tanks’ supremacy that they drove out to show off in front of the enemy lines to degrade his morale. Tanks often went far ahead of their infantry, only occasionally taking infantry riders.

American aircraft became more and more common starting with June 1950 and it was no longer possible to travel with impunity during the day. A prolonged stay at the front was also risky. Tanks were held far behind the front lines, only driving out to initial positions at night. The Americans also noticed that T-34-85 tanks appeared suddenly at night, writing that they travelled very quietly.

The KPA tankers still believed in their tanks. The POWs considered their tanks the best in the world, or at the very least on par with American medium tanks. At the same time, the knowledge of their own tanks was very poor. Tanks were often lost for technical reasons. There was no time for preventative maintenance during fighting, and tanks were usually used continuously until they broke down. The situation with batteries was the toughest, as there was simply no way to get any aside from taking them off disabled tanks. Tanks often had to be push started.

The radios performed very well, but only in the hands of qualified operators. As a rule, operators who arrived as reinforcements did their jobs poorly. The 9-RS radio had a range of 10-12 km in motion or 18-20 km when stationary. The intercom worked well, but crews preferred to give orders by touch and hand gestures.

One officer, a chief gunner of a tank company, deemed by the Americans to be very smart and eager to cooperate, said that the maximum range of the gun was 2-3 km, but the effective range was only up to 1900 meters. Less exceptional POWs evaluated the maximum range of the gun to be 1300-2000 meters, with shooting usually done at 600-1000 meters.

American research agreed with this figure, stating that 85 mm armour piercing rounds usually penetrated the Sherman from 800 yards (730 meters), but there were other opinions. For instance, Lieutenant Colonel Rogers from the 70th Heavy Tank Battalion estimated the maximum range from which a T-34 could penetrate the front of a Sherman tank to be 500 yards (460 meters). It’s possible that the North Koreans simply couldn’t hit a Sherman from a longer range. The Americans blamed poor training for this, as the POWs reported that only two rounds were fired during training. American impressions of the T-34-85’s gun sight were quite positive.

The American 76 and 90 mm rounds could penetrate the front of a T-34-85 tank from about 800 yards (730 meters), although the terrain was usually the limiting factor when determining the range of tank duels. The 75 mm guns of the aforementioned Chaffee tank, 60 mm Bazookas, 57 mm guns, recoilless rifles, and 105 mm howitzers were ineffective against the T-34-85’s front armour.

The North Koreans liked the T-34-85. One even claimed that the tank could fight any American heavy tank on even footing, although with the caveat that he has never seen an American tank on the battlefield. There were also complaints about the tank. The issue was generally with the turning mechanism, as it was hard to drive the tank and inexperienced drivers often broke them during training. There were also complaints about the engine, tracks, and transmission, also chiefly attributed to inexperienced drivers.

A souvenir from the Far East

POW interrogations were not the only measure of the T-34-85’s effectiveness. A captured tank was obtained by the end of 1950. The tank was incomplete and there were no spare parts to fix it. Nevertheless, even in this condition the tank was a good sample for study, as the Americans knew so little about even WWII era Soviet tank development that they had to base most of their opinions on German sources.

The Americans identified the tank as a late 1945 production vehicle and gave it the index G812. A brand new 1948 production engine was also obtained.

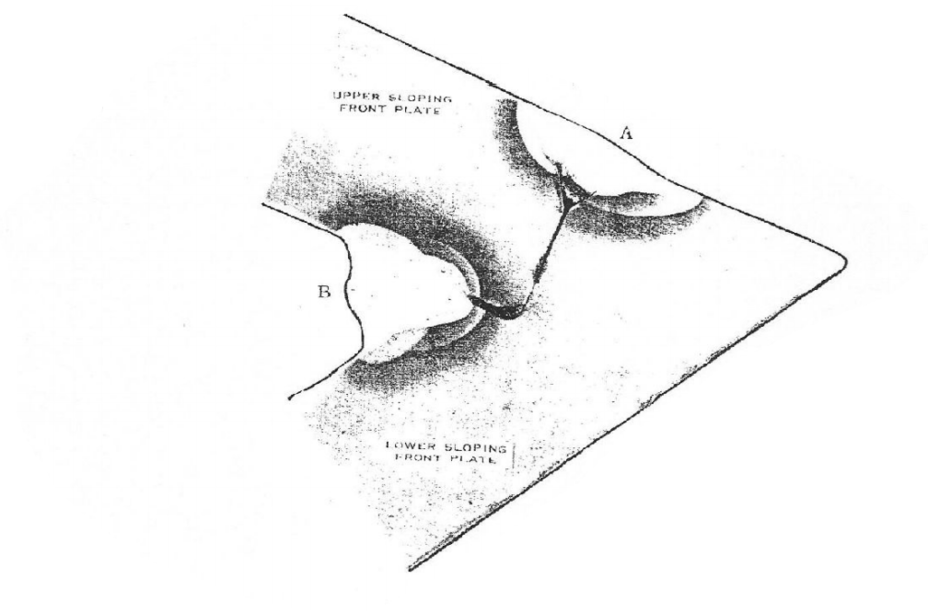

The armour of the captured tank surprised the Americans. Its hardness was 413-460 BNH, about 100 points higher than American armour of similar thickness. The impact strength of the armour was also higher. The hardening of the upper front plate was high quality, but the lower front plate was not as good. The casting, both of steel and aluminium, was high quality, without pitting or shrinkage. The side walls of the turret were an exception, but impact tests showed that the armour’s performance was equal or greater than the American requirement for lower hardness armour.

The quality of the rolled armour ranged from average to very good, and the thicker the plate, the higher the quality. The turret roof had the lowest quality. The automatic welding was of high quality, but the manual welding had some issues. Several of the seams had cracked. The Americans noticed the V-shaped front joint, which differed from the rounded connecting beam used on the T-34 tank tested at Aberdeen earlier. Many mounting points were discovered on the new tank that were not present on the old one.

The tank’s turret was welded together from cast and rolled components. Unlike the T-34 studied at Aberdeen, the radio in the T-34-85 was located in the turret, but only torn wires remained in tank G812.

The exterior finish of the tank’s components was rough, but the quality was high everywhere that it had an impact on the tank’s performance. Components were easy to access and service, which was made easier by small maintenance instruction labels scattered throughout the tank. The Americans determined that even a moderately skilled tanker would be capable of repairing the tank. It was easy to remove the engine or transmission due to a widespread use of light alloys and no shortage of lifting eyes. The quality of the paint was also high. The tank spent several weeks exposed to the elements after arriving from Korea, but few signs of corrosion were detected.

Traces of old components were detected. For instance, the engine had a mounting point for the old Pomon air filter, and the dashboard had an empty slot for the tachometer, which had since been moved to another location.

The engine on the tank was in good condition. According to the tank’s instruments, it had travelled for 741 km, but the level of wear on the engine was minimal. The quality of casting and finish was deemed high. The Americans noted that many symmetrical components were produced from the same blanks. Judging by the number of inspection stamps on each part, the quality control process at the factory was thorough. The Americans described the engine as similar to their Hispano-Suiza, but adapted for use on tanks. The German opinion that the fuel filter was copied from a Bosch design is also present in the report.

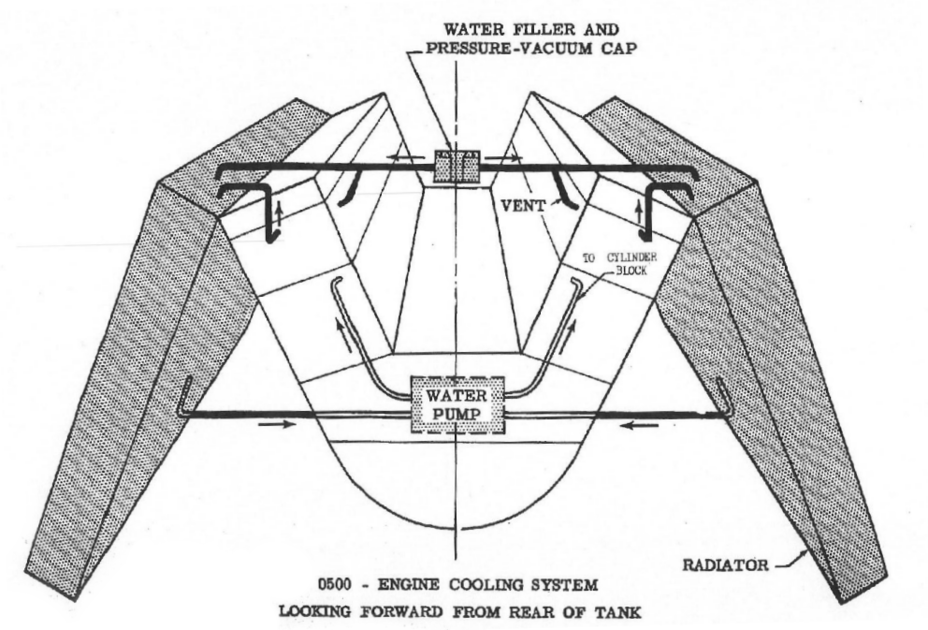

Specialists noted that the use of a diesel engine improves fire safety, but the two hand operated fire extinguishers filled with carbon tetrachloride present in the tank were judged insufficient. It was estimated that the poisonous fumes would force the crew out of the tank even if the fire was successfully put out before the ventilation system had a chance to clear the air. The air intake on the engine cooling system would have also helped.

The air filters also did not impress the Americans. The tank used a “tractor type” Cyclone filter, which replaced the “mushroom” Pomon filter seen on the Aberdeen tank. The new filter was well built, but its design was considered ineffective, as it would have to be cleaned daily, which the Americans deemed unacceptable.

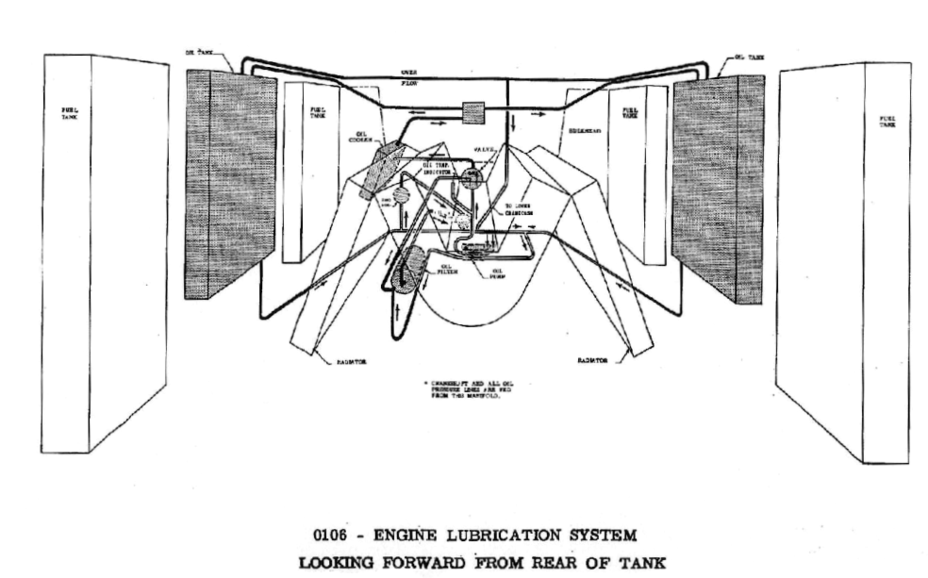

The cooling system was also judged as poor, mostly due to the quality of soldering on the radiators. The design of the radiators also left much to be desired. The cooling fins were made from copper and aluminium without any pattern, as though the radiator was put together out of scraps. The Americans concluded that these tanks could not fight in hot or dusty conditions. Nevertheless, this system was considered more effective than the one used on the Aberdeen tank, as the T-34-85 had an oil radiator, which the T-34-76 did not. The water pump drive that broke on the T-34-76 during the Aberdeen trials was also reinforced. The model 1948 engine electric generator had three additional cooling fans.

Compared to the T-34-76, the electric generator was reinforced. The Americans guessed that this was done to prevent damage from vibrations. Looks like this change worked, as the generator on the captured tank was in excellent condition. The report lauded the quality of several components, such as the starter relay, ohmmeter, and voltmeter. The dashboard was better laid out than on the T-34-76. The switches that used to be scattered all over the driver’s compartment were now all located on one panel. The batteries were in very poor condition by the time they arrived on the proving grounds and it turned out to be impossible to revive them.

The turret traverse mechanism allowed for coarse adjustments, with manual traverse for fine aiming. The gun elevation could only be adjusted by hand. The aiming mechanisms in the tank were high quality. There was no backlash when traversing the turret or elevating the gun. The quality of the electric motor was high, there were no signs of scorching. A clutch in the traverse mechanism protected the motor if the turret was pushed from the outside, for instance if the gun barrel hit a tree.

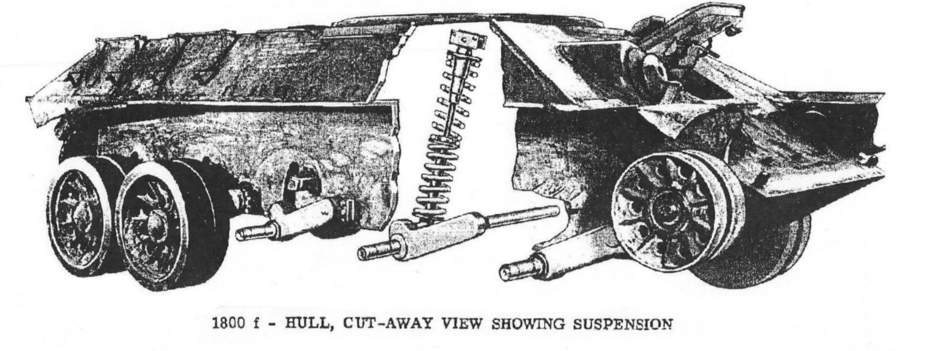

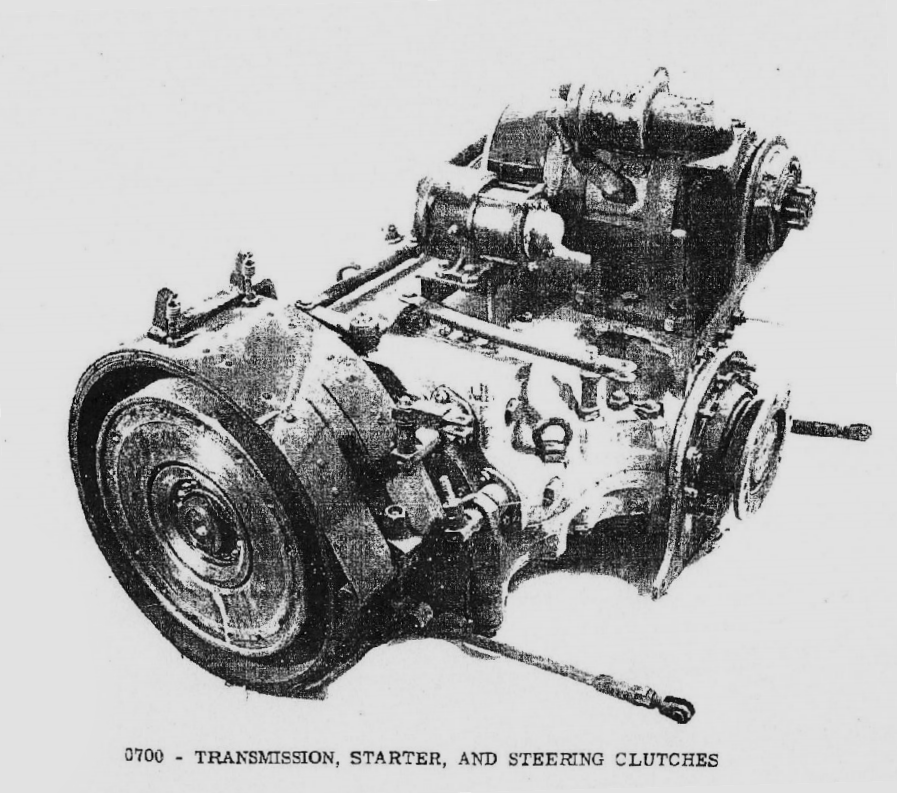

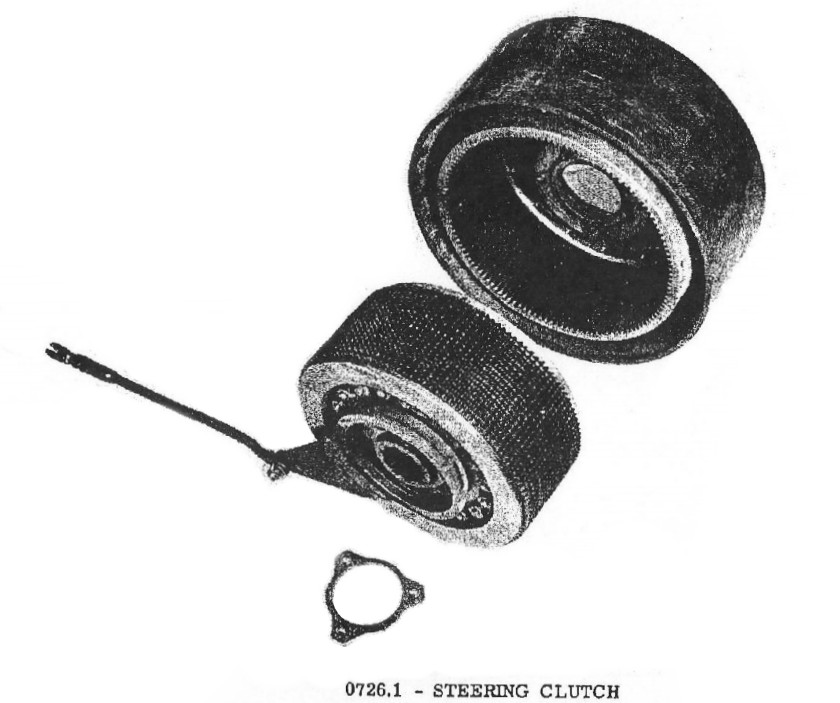

The steering of the tank was judged to be difficult due to having to control the tank using dry clutches in the final drives and a main clutch. The Americans noted that there were no signs of issues with clutch slipping as noted on the T-34 tank tested at Aberdeen. The clutch pedal also had an extra spring, which made it easier to operate. Unlike the Aberdeen T-34, the final drive clutches did not have ferodo liners. The gearbox gears were heavily worn, partially due to a lack of synchronization. The Americans noted that this heavy wear was only due to a defect in the lubrication system. The transmission was deemed to be the weak spot of the T-34-85.

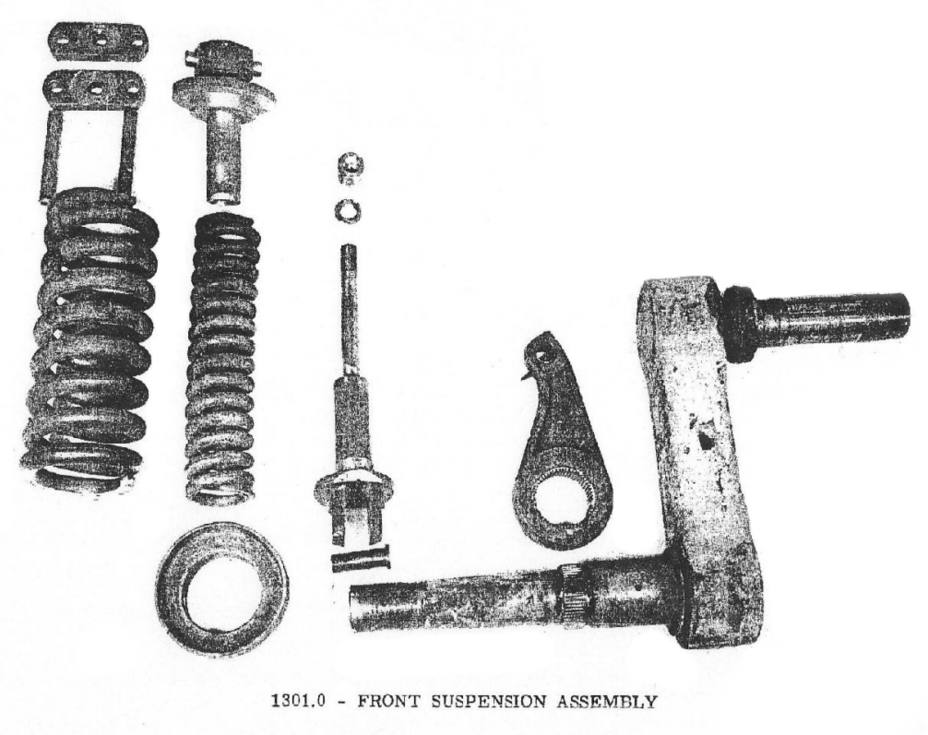

The tank had no shock absorbers, which would have made driving off-road a bumpy ride. A defect in this tank, missed by QA, led to a bend in the front suspension spring guide rods, which could have led to the tracks slipping off. The tank’s clearance of 16 inches (406 mm) was considered too small.

The quality of the fuel and oil tanks was considered high. The Americans noted that the total volume of fuel carried increased from 120 gallons (450 L) to 147 gallons (560 L). The quality of the fuel pump was considered high, but lower than an American equivalent. Its lifespan was judged to be 1000 hours.

As the T-34-85 was compared to more modern vehicles, some drawbacks described in the report look somewhat odd. For instance, the tank was criticised for not having a fume extractor or a turret basket, even though the M4A3E8 tank, the T-34-85’s contemporary, also did not have these features.

The Americans noted many positive qualities as well. Many aspects of the design were different from the tank that was inspected at Aberdeen, and the changes weren’t only done to simplify production. Most attempts to correct issues with the T-34-76 were successful. The combat effectiveness of the tank increased noticeably. The average ground pressure of 10 psi (0.7 kg/cm²) was considered optimal. American engineers themselves had issues getting to this number with their medium tanks.

The report also noted that the tank had an 85 mm gun, yet was much lighter than American tanks with similar armament. The report concluded that the T-34-85’s reputation of a reliable and resilient tank was understandable. Many of the components and assemblies of the tank were built from high quality materials, sometimes even higher than analogous components built in the USA. Some solutions were liked by American tankers, such as the sloped sides that were preferred over the vertical sides of their own tanks.

The analysis of the T-34-85 tank only served to highlight the low degree of training received by North Korean tankers. It was also noted that the tanks sent to North Korea were worn out in WWII, which had an impact on their effectiveness. The Americans knew that the USSR already had far superior tanks in service with better trained crews. It was clear that Soviet engineers were capable of sober evaluation of what qualities a tank needed to have on the battlefield and could create a worthy opponent for American tank.

Sources:

- Operations Research Office. The Employment of Armor in Korea. Volume 1

- Operations Research Office. US Armor in the Antitank Role. Korea, 1950

- WAL File No.710/930-4. Review of Soviet Ordnance Metallurgy

- CIA Information Report Number 00-T-00061. Engineering Analysis of the Russian T34/85 Tank