In 1942 the British asked the Americans to develop a tank based on the Sherman with improved armour. The Americans gave them the Assault Tank T14, but didn’t take much interest in the idea themselves. However, the idea of such a tank returned in 1944 and eventually culminated in the M4A3E2 or Sherman Jumbo.

Assault tank in a hurry

Until 1944 the American army was certain that the ordinary Sherman was more than capable of facing German medium tanks. Sure, the Germans had Tigers and Panthers, but based on experience in Africa and Italy these dangerous tanks were very rare. Nevertheless, the Americans decided to play it safe and develop a heavily armoured tank. It was clear that the Heavy Tank M6 was not suitable for battle and the Medium (future Heavy) Tank T26 would not be ready until the end of 1944 at the latest. US Army Ground Forces command proposed three temporary solutions in February of 1944.

The first idea consisted of a basic Medium Tank M4 with thicker armour. An extra 2 inches (50 mm) was welded to the front and 1 inch (25 mm) to the sides. This kind of modernization took 200 man-hours to complete and increased the weight of the tank by 6870 lbs (3.1 tons). This conversion could be performed in a field workshop.

The second variant called for not just adapting an existing tank, but development of a whole new hull and turret. This tank would have 4.5-5 inches (114-127 mm) of cast armour or 4 inches (102 mm) of rolled armour in the front. The upper hull sides were thickened to 3 inches (76 mm), the lower sides would be 2 inches (50 mm) thick, half an inch (12.7 mm) was added to the rear. Such a tank would weigh 37 tons. This was not quite enough for a fully fledged heavy tank, but its armour would be better than a Panther’s at a much lower weight, and in some places even better than a Tiger’s.

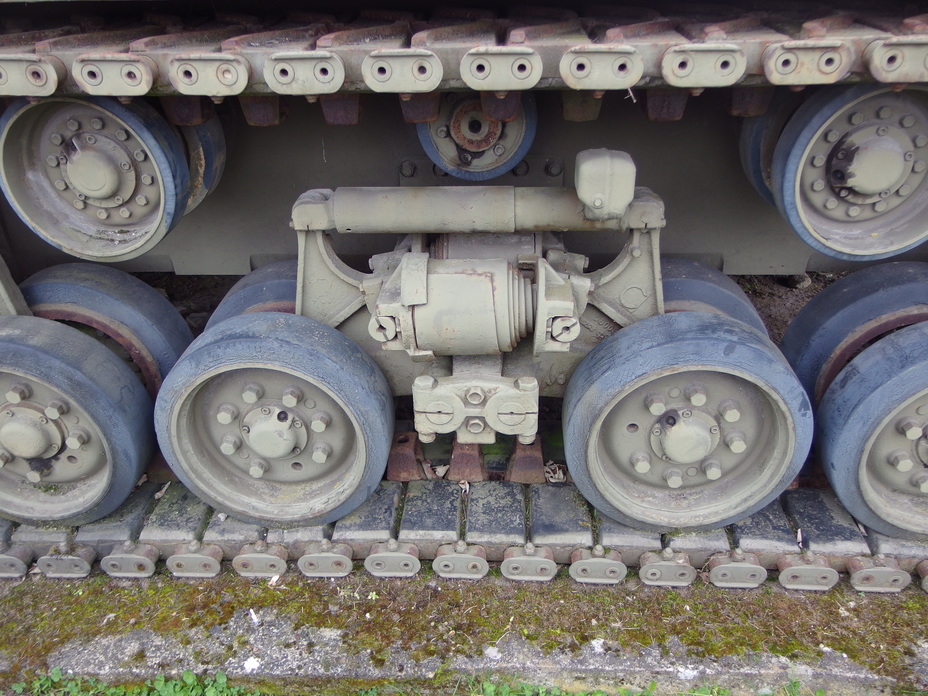

There was also the issue of the drivetrain. The AGF advised a change in gearing to reduce the top speed from 24 mph (38.6 kph) to 18 mph (29 kph). This idea was tested on February 18th. An ordinary Sherman was loaded up to 37 tons. Small auxiliary springs were added to the suspension in order to deal with the extra weight. The tank completed a 500 mile (804 km) circuit without much issue, with the exception of road wheels that had to be changed every 50 miles. Even with extended end connectors, the ground pressure of the tank increased from 0.76 to 1 kg/cm². The idea of using the new HVSS suspension with wider tracks was considered, but even that would be a half-measure as the new suspension was designed to handle a 34.5 ton vehicle.

There was another variant proposed. The front turret armour reached 8 inches (203 mm) in thickness, the sides were 3-5 inches (76-127 mm) thick. This tank would weigh 41 tons and have a ground pressure of 1.12 kg/cm² with extended end connectors or 1.31 without them. It was never built.

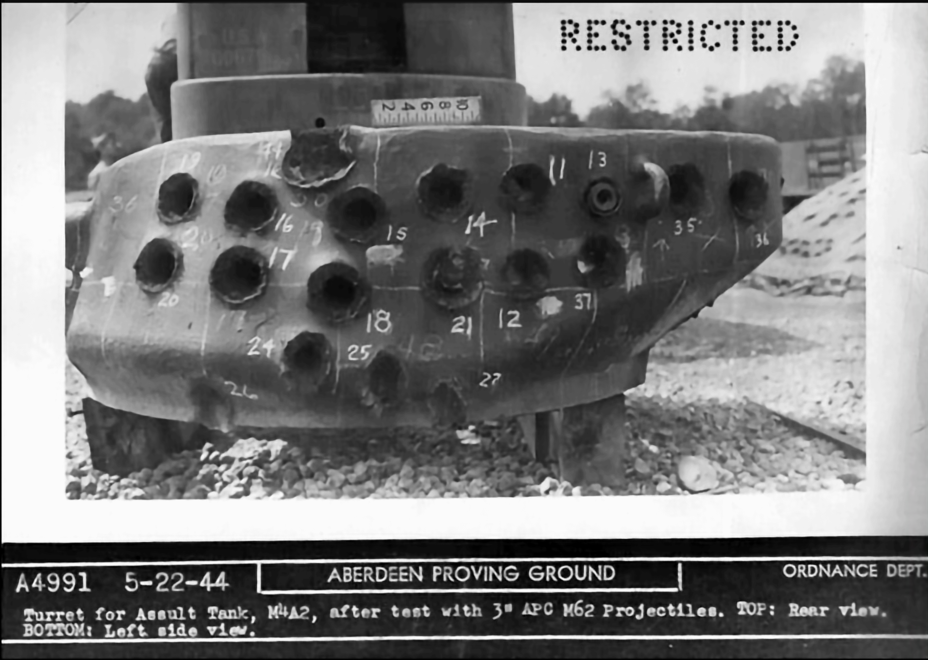

The concept of the new assault tank was formed by March of 1944. The turret was developed from scratch based on the T23 tank’s turret. The difference was thickness: the turret armor was 6 inches (152 mm) thick all around, even in the rear. A bulge with a ventilation fan was located in the back. The roof was made from ¾ inche (19 mm) thick rolled armour and welded on separately. Unlike T23 turrets where openings were cut in the turret basket floor to allow access to ammunition, this turret kept it as is. Other new features of the T23 turret such as a loader’s hatch and commander’s cupola migrated over as well. The pistol port was absent.

The gun mount, indexed T110, was similar to the M62 mount used in the T23 tank, but it carried a 75 mm gun. The mantlet thickness was much greater: a 5 inch plate was welded to the 2 inch mantlet for a total of 7 inches (178 mm) of armour. Cuts were made in the sides of the mantlet to allow the driver and assistant driver to open their hatches. Despite the massive counterweight welded to the mantlet, the gun was breech-heavy. Theoretically, a 76 mm gun could be installed in this mount, but then it would be muzzle-heavy. The turret with armament and the turret basket weighed 20,510 lbs (9303 kg).

The ammunition stowage was the same as on the regular M4A3(75)W. Six rounds of 75 mm ammunition were stored on the turret basket floor. There were 100 rounds in racks under the floor, but to access them the turret had to be traversed to the correct position and doors in the floor had to be opened. This took a lot of time.

The 5.5 inch (140 mm) thick cast differential cover was also designed anew. 1.5 inch plates were welded to the sides and front of the tank. The front armour was 102 mm thick (positioned at an angle of 47 degrees) and the sides were 76 mm thick. The dry weight of the tank was 36 tons, when fully stowed (sans crew) it weighed 38.3 tons. The ground pressure with extended end connectors reached 1 kg/cm². The new tank was indexed M4A3E2.

An M4A3(76)W tank was tested to see how it would be affected by this weight. One tank was loaded to 37.6 tons and ran through 474 mile (763 km) long trials. The tank worked well and oscillated less than an ordinary M4A3(76)W. One road wheel tire peeled off after 70 miles (113 km) of travel, but this was the only failure of this type.

A 1225 kg weight was added to the turret to test the traverse mechanism. The weight of the tank reached 38.8 tons. It was taken through 6 mile long special trials, which it completed successfully. Trials showed that the 7 ton turret could be traversed without issues. It took 8-9 kg of effort to turn it on a 16.7° slope and 11-13 kg on a 21.8° slope. The Oilgear powered traverse worked normally.

Trials did not uncover any serious defects. Despite the success, testers recommended installing an experimental running gear with extended end connectors on both sides of the track. Another interesting variant was also proposed. The British heard about this tank and considered it possible to install a 17-pounder gun in it. In this case, the turret basket floor would be removed, as it got in the way of loading the long and heavy 17-pounder rounds.

Since the vehicle had a specific purpose and was considered a temporary measure, only 250 units were ordered. The British showed interest in this tank in the summer of 1944, but their order was denied. The Americans expected to finish production in July and no more tanks of this type were planned.

A treadmill for an overweight tank

One production tank was sent to Utica in June of 1944 for trials. A suspension bogey broke after just 60 miles (100 km) of travel. Testers noted that the tank should be driven very carefully. The top speed was limited to 12 mph (19 kph). Testers tried to improve the lifespan of the suspension springs, but fruitlessly. Even bogeys with heavy duty volute springs and auxiliary coil springs broke quickly. For instance, after a 474 mile (763 km) drive five of the 12 auxiliary springs had broken. American specialists wrote that it was impossible to design a satisfactory suspension for such a heavy tank with vertical volute springs, but it was too late to make any changes. Production already ended.

A tank arrived at Fort Knox for trials by August 18th. The tank was measured and weighed. The empty tank weighed 36.8 tons, with equipment and crew it weighed 39.2 tons. There was no rush to perform trials. Mobility trials finished only by February 18th, 1945, and even then the course was shortened to 580 miles (933 km). The top speed of this tank was claimed to be 23 mph (37 kph), but the real top speed was just 18-20 mph (29-32 kph).

In practice, the M4A3E2 turned out to be much slower than its predecessors. It took 5 minutes and 18 seconds to finish a course that an M4A3 could do in 4:17.5 and an M4A1 in 4:44. Mobility in mud and on slopes was low. The top reverse speed (2.3 mph or 3.7 kph) was deemed insufficient. Six road wheels broke during the trial. Gunnery trials were completed successfully. It took 2-3 times more effort to turn the turret than on an M4A3(76)W tank, but this was still acceptable. The Ordnance Board evaluated the vehicle as overweight, but acceptable for service at low speeds. Development of a tank with an HVSS suspension, thicker side armour, and higher reverse speed was recommended.

Further trials showed that the Ordnance Board was completely correct. The designers should not have disregarded the HVSS suspension. Trials of M4A3E8 tanks loaded to 41.7 and 46.3 tons were completed by November of 1945. The lighter tank drove for 4000 miles (6437 km) on frozen dirt over the course of 273 hours, giving an average speed of 14.6 mph (23.5 kph). To compare, an ordinary M4A3E8 driving through the same course reached an average speed of 15.8 mph (25.4 kph).

The 46.3 ton tank drove for 1366 miles (2198 km) with the stock transmission, after which it was replaced with one that had a higher gear ratio. The average speed grew from 12.8 mph (20.6 kph) to 13.8 mph (22.2 kph). The heavier tank travelled for 3950 miles (5777 km) in total. The lighter vehicle lost 8 road wheels during these trials and the heavier lost 17. Even though the heavy tank had heavier duty volute springs, both tanks lost 6 springs during the tests. 12 shock absorbers broke on the first tank and 16 on the second. This reliability is not impressive, but keep in mind that both tanks were heavier than the M4A3E2 and their average speed was comparable with that of an unmodified Sherman.

The HVSS suspension was used on one variant of the vehicle designed for the Pacific theatre of war: the Assault Tank T33. This tank also received a new turret with a flamethrower mounted alongside the 75 mm gun. Since the war ended, this tank was not mass produced. Only three vehicles were converted.

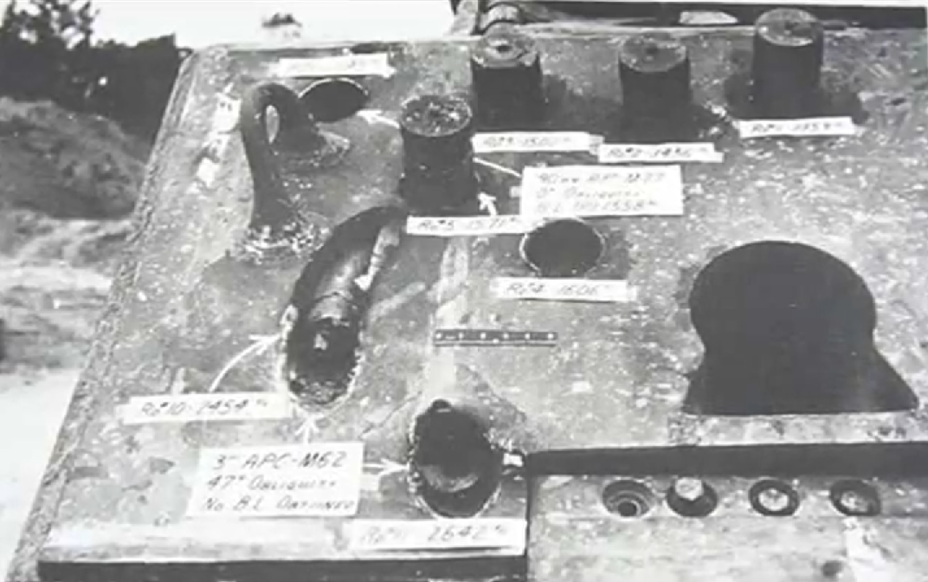

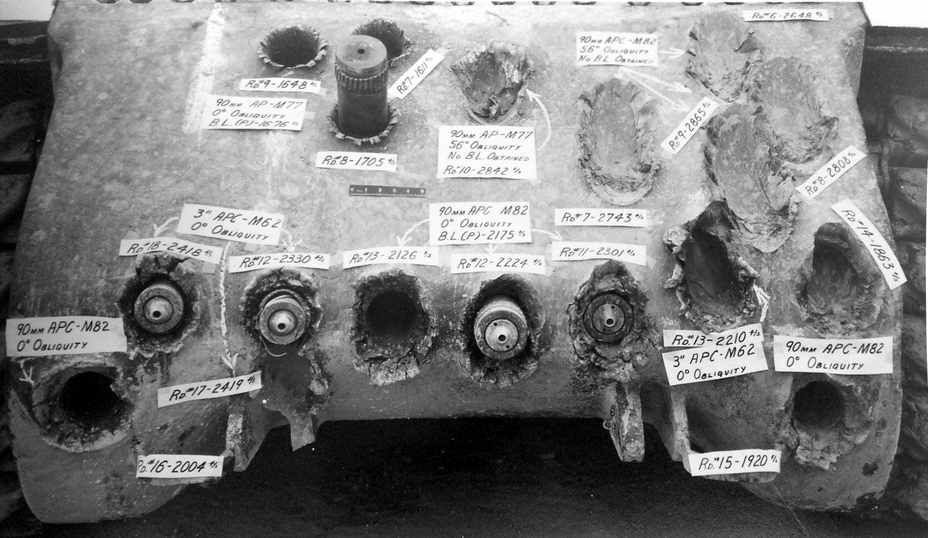

The tank’s main feature, the armour, was also tested thoroughly. The turret was put through trials by the end of 1944. The M4A3E2’s armour turned out to be tough, but not impenetrable. The armour was thick, but not as hard as it could have been at 201-212 BNH. Specialists at Watertown laboratories considered this to be a consequence of casting such thick armour with necessary ductility. Crystalline fractures were detected in lab tests, but they were not frequent. The specialists considered the armour to be satisfactory in regular conditions, but prone to cracks at temperatures of −40°C. Impact toughness was deemed low. Overall, the testers deemed the armour quality sufficient for its thickness, predicting that if the hardness was increased it would quickly become brittle.

Trials showed that the sides of the turret could be penetrated from 300-400 yards (274-366 m) with the American 76 mm gun or up to 1400 yards (1280 m) with the 90 mm gun. Hits from 90 mm shells at angles of 30 and 45 degrees resulted in minor damage to weld seams. Firing at the gun mantlet with 90 mm rounds at a velocity of 2300 fps (700 m/s), which corresponded to a range of 2100 yards (1920 m), resulted in partial penetrations. The trunnion bearings were destroyed and the gun became difficult to elevate. The weld seams that held the counterweight in place cracked.

The rear of the turret also had its weaknesses. 37 and 75 mm shells could ricochet off the bustle and penetrate the hull roof.

The bolts holding the turret ring and turret traverse mechanism burst under fire from 90 mm guns. Replacement bolts were installed which bent under fire, but did not break.

The front of the tank gave similar results. The ballistic limit against the 90 mm gun was equal to 2677 fps or a range of about 500 yards (457 m), while the 90 mm gun would not have been able to penetrate a monolithic 102 mm thick plate at 47° from any range. The 76 mm gun only achieved a partial penetration when firing at point blank range, the same result as for a monolithic 102 mm plate. The glacis plate deformed when hit and a 76 mm gap formed between it and the differential cover. The horizontal weld seam burst, but the vertical ones held.

Even a 76 mm round managed to penetrate the 5.5 inch (140 mm) thick differential cover at normal with a velocity of 2330 fps, which corresponded to a range of about 650 meters. The same section could be penetrated with the 90 mm gun from over 2.5 kilometers. Thinner parts of the armour could be penetrated from even further away. The bolts holding the differential cover burst when it was hit, andthe cover shifted inside the tank.

The sides were also far from invulnerable. The 76 mm gun could penetrate them from 1500 yards (1370 m) at an angle of 45°, which was much further out than the range at which it could penetrate a 3 inch monolithic plate at the same angle. Cracks were wound even in cases where there was no penetration, although the hull never fell apart.

The armour could be penetrated, but trials showed that the tank was much better protected than the Sherman. For comparison, the front of a Sherman tank (51 mm at an angle of 56°) could be penetrated with the 76 mm gun from 640 meters and the 90 mm gun from 2.5 kilometers.

Better late than never

Tanks produced in the summer of 1944 didn’t make it in time for the Normandy landings. M4A3E2 tanks only started reaching the front lines in the fall of 1944.

The tactics used by these tanks were usually as follows. As the ground was saturated with the fall rains, Sherman tanks could only drive along narrow roads. The loss of the head tank could result in the death of the entire column, as the rest of the tanks would have nowhere to hide from German anti-tank guns. This is where the M4A3E2 came in handy. These tanks could easily survive a hit from the 88 mm Flak 36 AA gun, let alone much more common 75 mm Pak 40 guns. Putting these tanks at the head of tank columns gave excellent results.

The tanks proved that they could hold a hit from even 88 mm guns in practice. For instance, in November of 1944 the 743rd Tank Battalion recorded 3 hits from an 88 mm gun at a range of 800 yards (731 m). One round ricocheted from the front plate, two more bounced off the turret, and only the fourth hit the sight opening and destroyed the tank. On November 14th, 1944, one tank from the 6th Armored Division took 6 hits from an 88 mm gun without a single penetration.

Even senior commanders were impressed by the tank’s performance. Patton’s Chief of Staff reported that every tanker wants a tank like this. The commander of the 6th Armored Division recommended reallocating 2/3rds of tank production to the M4A3E2 and the remainder to Shermans armed with 105 mm howitzers. Eisenhower telegraphed Washington with an exceptional review:

“The M4A3E2 assault tank has proved itself in combat and has been most favourably received. The theater has an immediate requirement for the maximum number that can be produced without materially reducing the flow of tanks to the continent.”

Alas, there would not be any more of these tanks. Production ended after the first batch of 250 vehicles (plus 4 prototypes) and was never restarted.

The tanks were good, but not ideal. For instance, crews complained that the armament remained the same as a regular Sherman’s. Thankfully, 100 spare 76 mm guns were on hand, 45 of which went to re-arm M4A3E2 tanks in Patton’s 3rd Army. Other tanks also received the E4-5 flamethrower instead of the bow gun, but this conversion proved unpopular as the flamethrower was ineffective.

Every soldier wants a tank with a bigger gun and thicker armour. The M4A3E2 realized at least one of these wishes. The US Army received a tank with the weight of a medium but armour superior to that of the Panther. Reliability had to be sacrificed, but American repair workshops worked flawlessly and crews did not complain about it.

Unfortunately, there were just too few of these vehicles built. Compared to tens of thousands of M4 tanks, the M4A3E2 was just a drop in the bucket. Cancellation of strange projects like the Assault Tank T14 in favour of the Heavy Tank T26 was a reasonable move, but it’s hard to tell why the much more promising M4A3E2 was built in such small numbers. Attempts to improve the tank’s mobility were also lethargic: the HVSS suspension, specifically designed to support heavier Shermans, was only installed on three tanks, and the much simpler E9 running gear was not even tried.

It is often asked why there were so few Pershing tanks in Europe. The cause of this shortage is much more obvious, as shipping the heavy and untested tank to a different continent was a risky proposition. However, the M4A3E2 was much lighter than the Pershing and built using tried and true components. Unfortunately, no one could predict the future, and it just so happened that a quite successful vehicle was only produced in miserly quantities.

Sources:

- Watertown Arsenal Laboratory: Memorandum Report No.WAL 710/681

- Steven J. Zaloga M4 (76 mm) Sherman Medium Tank 1943-65

- Steven J. Zaloga Armored Thunderbolt: The U.S. Army Sherman in World War II

- Archive of the Canadian Military Headquarters, London (1939–1947), RG 24 C 2