The SU-76M SPG, armed with the ZIS-3 76 mm gun, was the second most numerous vehicle in the Red Army. This gun was one of Grabin's best, and had very respectable characteristics. Nevertheless, the idea of installing a more powerful gun was persistent, and some variants, such as the SU-85B, came close to entering production. However, the Red Army never received its domestic Marder.

Getting rid of an unneeded gun

The idea of creating a tank destroyer came up at the stage of developing the SU-12 and SU-71, the SU-76M's direct predecessors. This vehicle was supposed to receive the M-42 45 mm anti-tank gun. However, the development of this vehicle did not progress past development of tactical-technical requirements. Meanwhile, Grabin's other gun, the 57 mm ZIS-2, appeared and disappeared from SPG armament requirements regularly.

The ZIS-2 and its tank version, the ZIS-4, came up once again in the spring of 1943, after trials of a captured Tiger tank. The ZIS-2 was one of the few Soviet guns that could penetrate the German tank from the front, as well as the side. Even though the range would have to be very close to defeat the Tiger's front armour, the ZIS-2 was put back into production.

The idea of developing a tank version of the ZIS-2 came from the Main Artillery Directorate (GAU). Grabin and factory #92 displayed their initiative. Mass production began alongside production of four prototypes used to arm T-34 tanks. While tanks with the new guns were being tested, the factory built over 150 of these guns. The ZIS-4 was also tested on the experimental SU-74B SPG. Compared with the variant developed in 1941, this ZIS-4 was easier to produce.

The first phase of the Battle of Kursk concluded right as the T-34s with the ZIS-4 arrived for testing. It became clear that the ZIS-4 was no longer suitable as armament for tanks. The Germans brought a number of new vehicle to battle, including the Panther, which had an upper front plate that could not be defeated by the 85 mm AA gun. The future of the ZIS-4 seemed bleak.

ZIS-2 production continued, but ZIS-4 production was shut down. However, factory #92 jumped the gun, and 154 ZIS-4 guns collected dust at factory #183's warehouses in Nizhniy Tagil. 12 more guns produced in 1941 were also stored at factory #183 since its evacuation from Kharkov.

Needless to say, the gun wasn't getting any better with time. Requests were sent to deal with this rusting junk. The GAU and GBTU were in a difficult spot. The 57 mm gun was still valuable in battle, but they had no future in the tank forces. By late 1943 the decision in favour of 85 mm guns had already been made. The solution was using the ZIS-4 to arm SPGs.

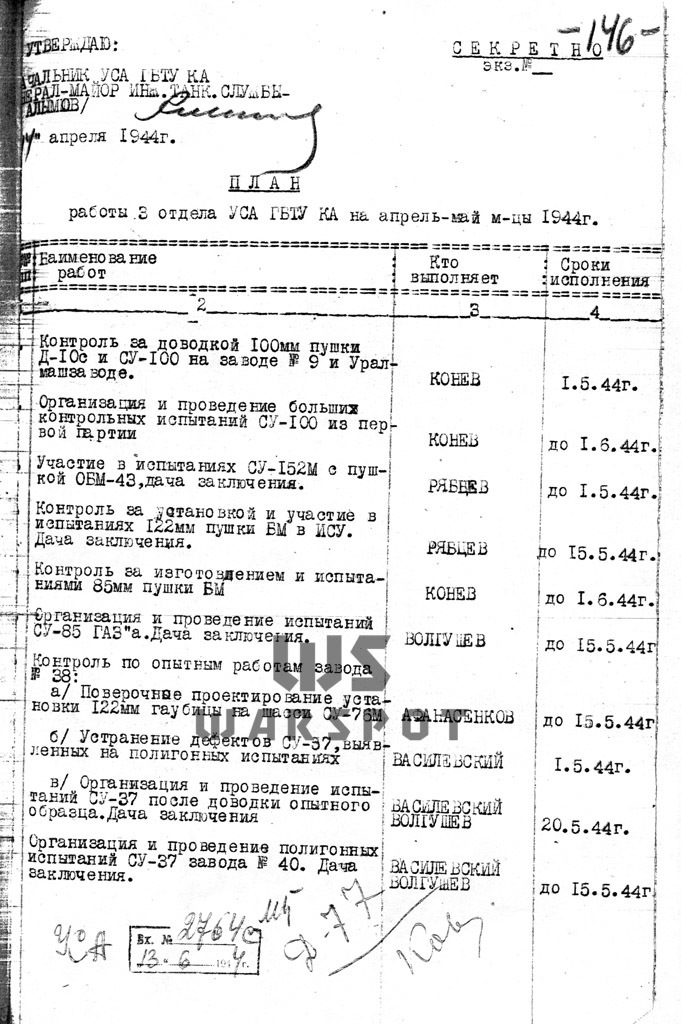

The story of the long-suffering guns continued with more initiative, this time on behalf of the design bureau of the Molotov GAZ factory. This design bureau developed an SPG named «57 mm self propelled gun» in April of 1944. The commonly used index SU-57 appeared much later, in September of 1944. GAZ didn't reinvent the wheel. The SU-76M design was unchanged, only the barrel was replaced. Considering that the ZIS-2 and ZIS-3 had many interchangeable parts, this was not an issue.

Interestingly enough, some documents claim that the SU-57 development was GAZ's initiative, others claim that it was designed in agreement with the GAU and GBTU. There is also a third version of the events. A document dated April 24th, 1944, says the following:

«Based on personal discussion between the Chief of the Main Artillery Directorate of the Red Army, Marshal of Artillery comrade Yakovlev, and the People's Commissar of Medium Manufacturing, comrade Akopov, the Gorkiy Automotive Factory was instructed to build an experimental 57 mm anti-tank SPG consisting of the oscillating part of the 57 mm anti-tank gun model 1943 installed on the SU-76M self propelled gun chassis.

Since this task is very urgent, I ask you to order the production of an experimental prototype by May 1st of this year and its immediate delivery to the Experimental Artillery Scientific Research Proving Grounds for trials. The ANIOP has received orders to perform trials within three days.»

Considering that the trials program was signed on April 27th and trials performed on May 1st-4th, it's hard to claim personal initiative.

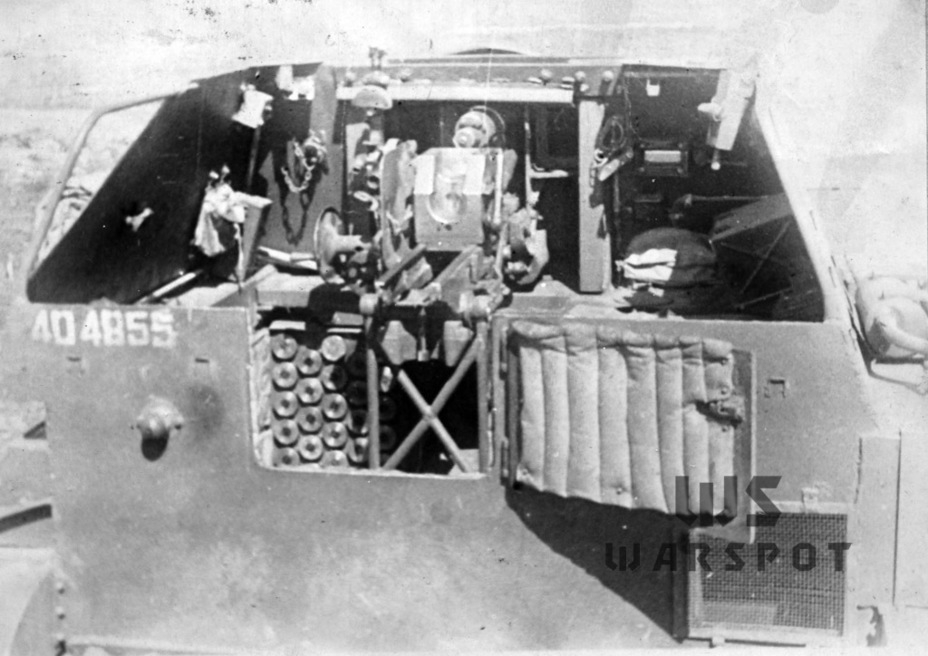

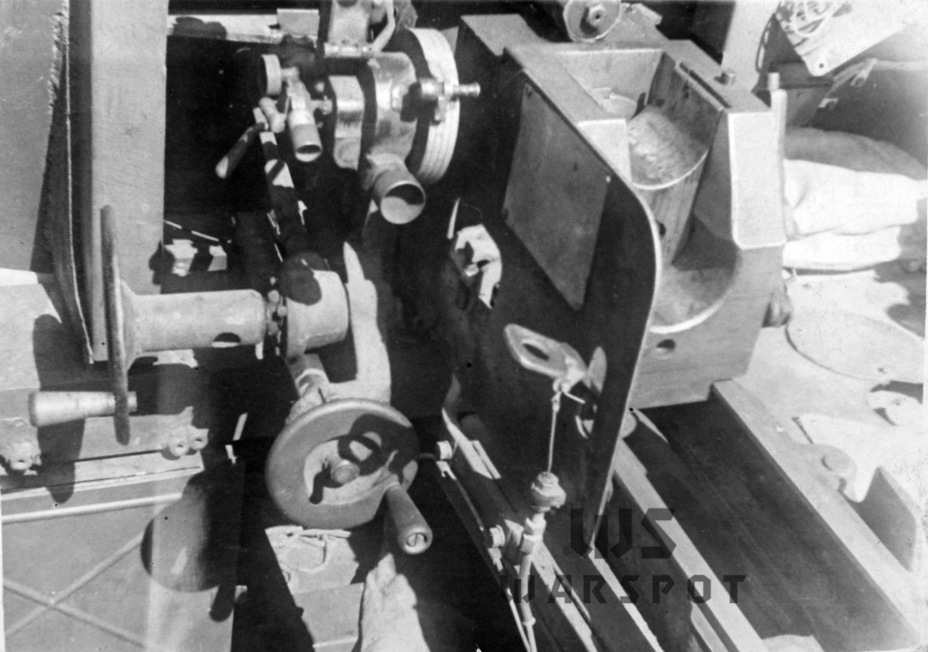

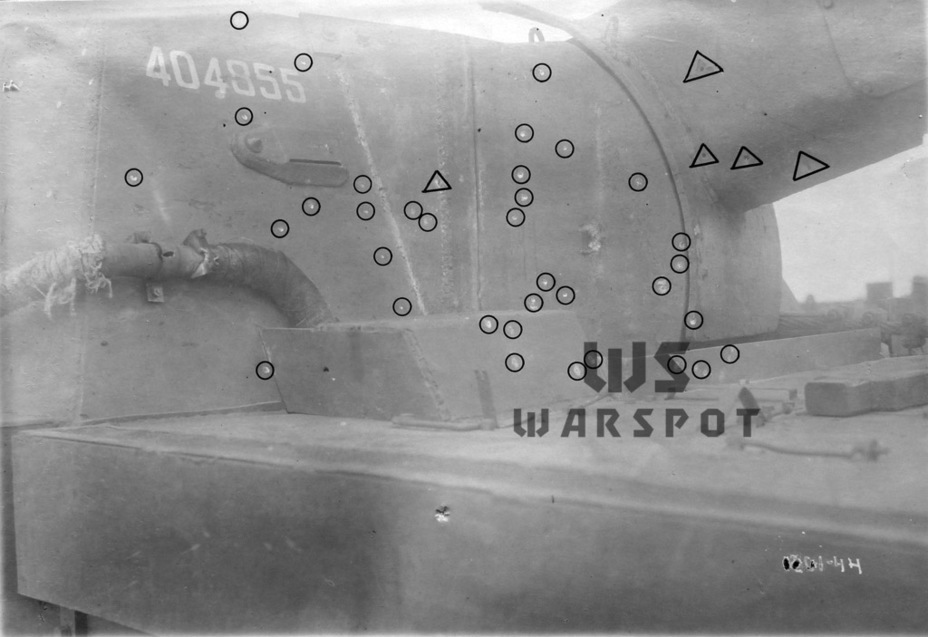

A production SU-76M with serial number 404855, from April 1944 production, was used to produce the prototype. Its first trials took place on April 30th at the factory. 25 shots were fired, 20 of them with increased charge. The ANIOP fired 270 more shots, 107 of them were using the increased charge. The precision of the HE shell was deemed satisfactory, but the precision of the AP-T shell was not satisfactory. This was not the problem with the SPG, but the gun. Similar issues were pointed out at the ANIOP during trials of the ZIS-2 in the fall of 1943. Results with the subcaliber shell was better.

Aimed rate of fire was 10 RPM, maximum rate of fire was 15 RPM. The testers did not like the sights. The SU-76M did not receive the entire ZIS-2 gun, but only the barrel. The ZIS-3 panoramic sight, poorly suited for firing at moving targets, was still used. The fighting compartment, partially open from the rear and the sides, was also criticized.

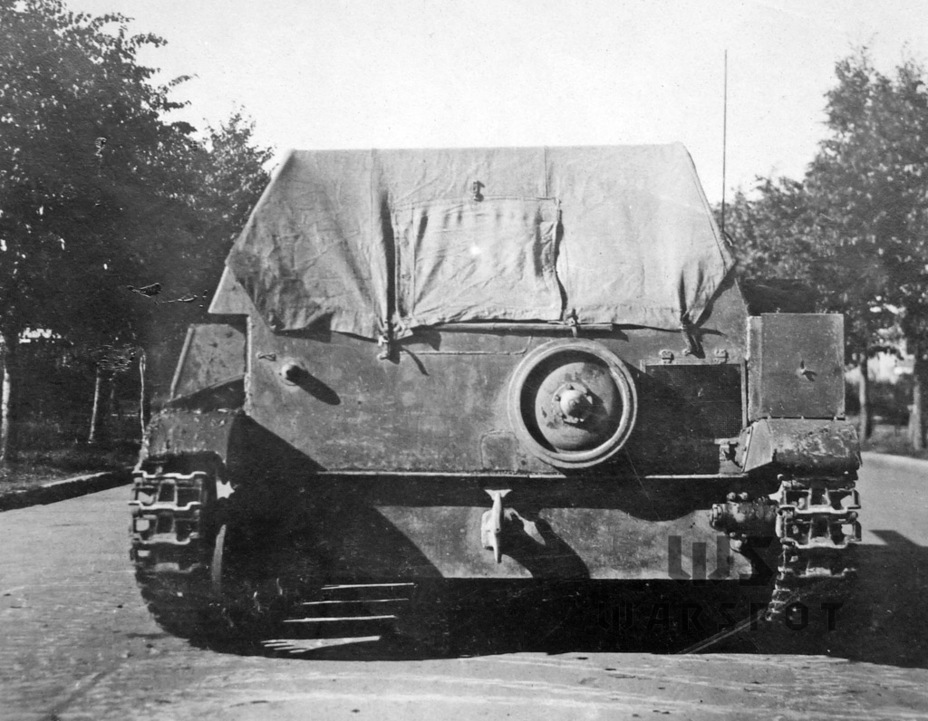

The experimental SPG passed trials, but a number of changes had to be made. Instead of a panoramic sight, the telescopic 10-T had to be installed. An electric firing mechanism with the trigger located on the elevation flywheel handle was needed. The fighting compartment also had to be entirely enclosed. The roof was to be built from 5-8 mm thick steel, the sides would be 15 mm thick. The crew would exit through a two piece hatch in the rear.

The GAZ designed a second prototype, having taken these requirements into account. The existing prototype was converted instead of making a new vehicle. The fighting compartment changed the most. It was now entirely closed. The mass was reported to be the same as the SU-76M, which is doubtful. It likely grew by about half a ton. Periscopic MK-4 observation devices were installed in the roof to improve visibility. The armament was changed in accordance with the requirements.

The prototype arrived at the Gorohovets ANIOP on June 29th, without blueprints or documents. It went though firing trials on the next day, but stopped, since the ANIOP had a more pressing task. Due to issues with fuel, trials were paused between July 5th and 28th, and were only completed on July 30th. The SPG made 358 shots, 113 of them with increased charge. The rate of fire and precision did not change. The precision when firing at moving targets was worse, but this had to do with the fact that the firing was performed according to firing tables for the 85 mm gun, since that was the scale that was applied to the 10T-15 sight.

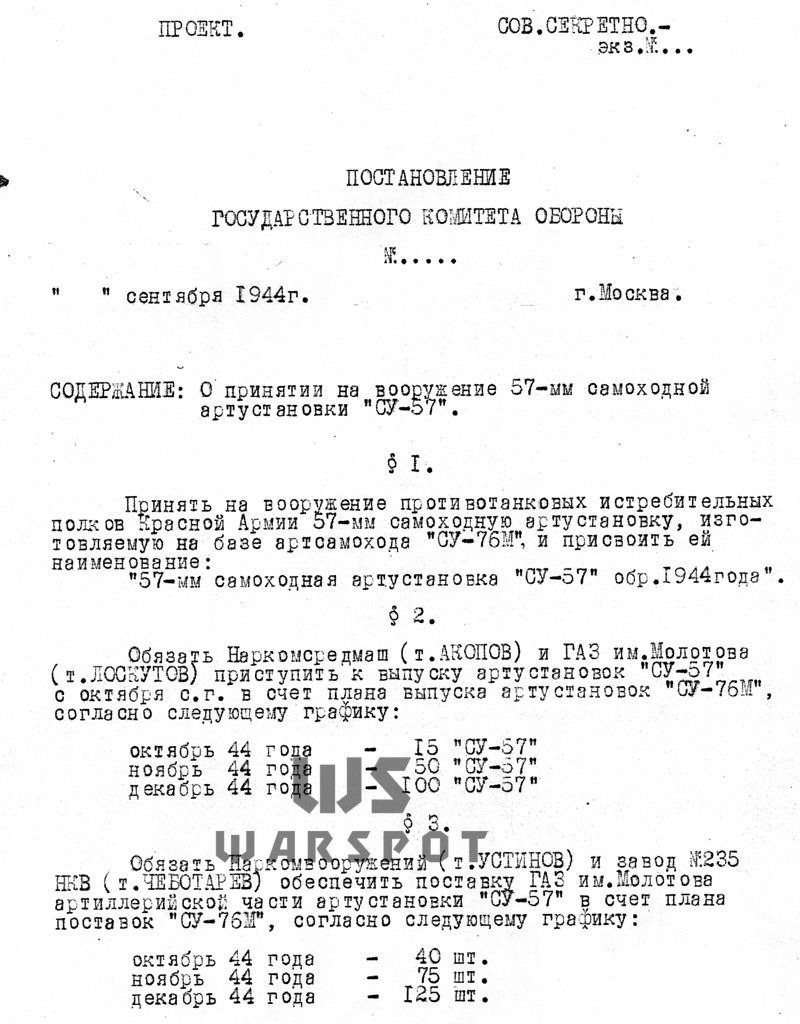

There were few benefits from the conversion. The enclosed fighting compartment was liable to fill up with fumes. Nevertheless, the Artillery Committee decided that the vehicle passed trials. A GKO decree that accepted it into production was drafted in September of 1944. 165 of these vehicles were scheduled to be built at the GAZ in the fourth quarter of 1944.

This was when the Self Propelled Artillery Directorate (USA) of the GBTU started to actively oppose the introduction of the SU-57. A list of drawbacks was composed, for instance the insufficient armour of the vehicle. Attempts to push production through continued until 1945. By then the SU-57 was completely useless, especially considering that the Molotov GAZ factory designed a much more powerful SPG by mid-1944.

Moving to a medium caliber

In the summer of 1943 it became clear that the penetration of the ZIS-2 was no longer enough to combat newest German tanks. The SU-85 GAZ SPG was designed and built at the Molotov GAZ factory under the direction of N.A. Astrov in late 1943. This vehicle was a further development of the GAZ-74 SPG, with not only a more powerful weapon, but thicker armour. At a mass of 14.5 tons, the front armour was 82 mm thick. Trials took place from January 3rd to March 8th, 1944, and completed successfully, but further development did not take place.

This was the consequence of A.A. Lipgart's resistance to Astrov's product. In late 1943, the chief designer began a quiet (and sometimes not so quite) fight against military production at GAZ. Andrei Aleksandrovich was not a saboteur: he merely had the rebuilding of the factory for peacetime needs in mind. Furthermore, the GAZ-75 was a radically different vehicle, and the factory would have to be seriously reconfigured to build it. Since SPG production had to be increased, implementing the GAZ-75 into production would not have been possible.

Attempts to continue improving the armament of light SPGs did not die with the GAZ-75. The factory's design bureau decided to design an improvement to the SU-76M instead of a whole new vehicle in May of 1944. This work became possible due to the attitude of the Military Acceptance department, chiefly Engineer-Colonel Okunev. The new project was indexed SU-15A. The index GAZ was not used, since the chassis was the SU-15M, which was developed by factory #38's design bureau.

SU-15A development was headed by Astrov, I.V. Gavalov became the lead engineer. Igor Valentinovich often had to solve difficult engineering issues in his career, and this was no exception. A gun that was initially designed for medium and heavy tanks had to fit into a light SPG.

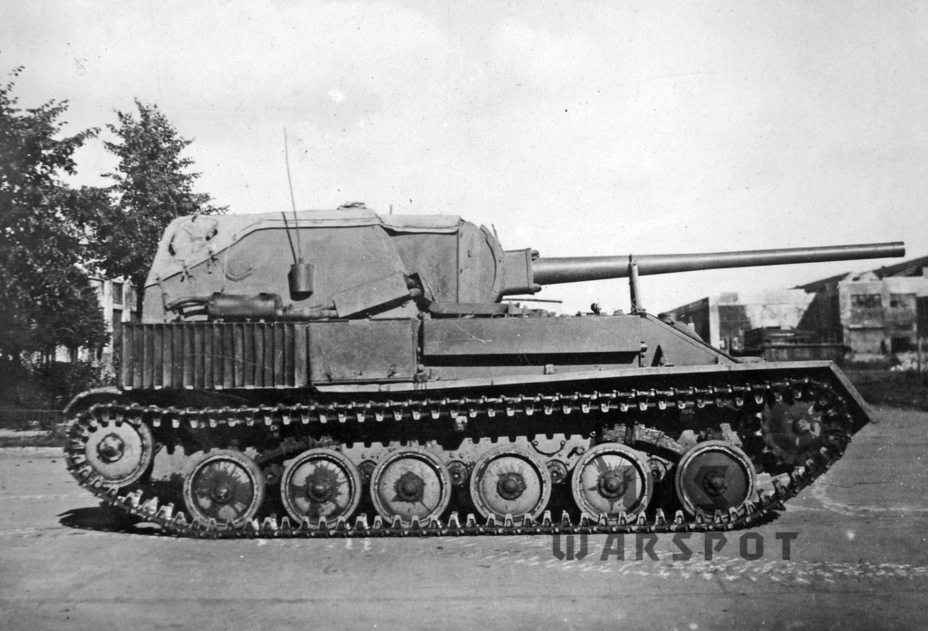

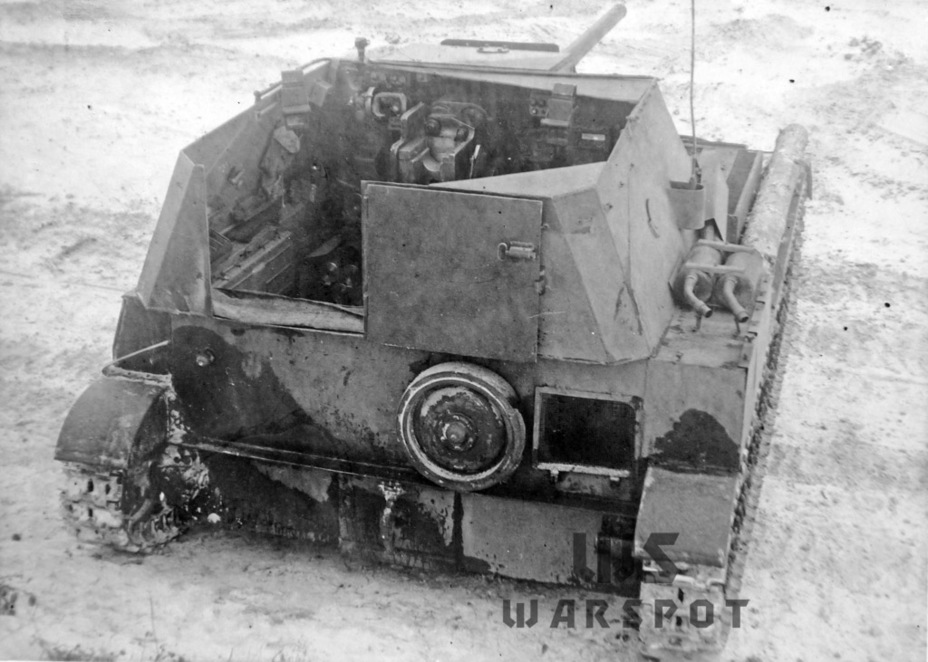

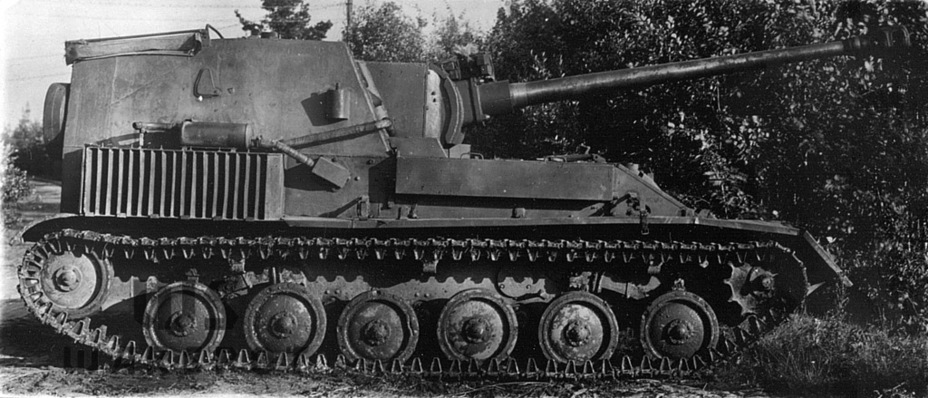

Several variants were laid out in May of 1944. The simplest was chosen: the 85 mm D-5S-85 was installed into the existing SU-15M hull. The gun mantlet was similar to the one used on the GAZ-75. The rear of the vehicle was changed. The lower rear plate became vertical to increase the space inside the fighting compartment. Since the mass increased to 12 tons, the suspension would have to be reinforced. The front and rear road wheels received leaf springs for additional cushioning. Rails were installed instead of return rollers.

To ensure the ability of the light chassis to carry the D-5S-85, this system was installed on an ordinary SU-76M in May of 1944. Firing trials showed satisfactory results. This vehicle was shown to the Marshal of Armoured Forces, Fedorenko, who approved it.

Lieutenant-General Vershinin asked the Molotov GAZ and factory #9 to develop another SPG in late May of 1944. The 122 mm M-30 would be installed in the SU-76M. Instead of GAZ, factory #38 took on this project, as they had been working on a similar topic since April. Alas, the work was cancelled in July of 1944 in connection with the move of factory #38 from Kirov to Kharkov, to the grounds of factory #75. Not even a draft was completed, unlike the OSU-76 and ZSU-37, which were transferred to factory #40. The light self propelled howitzer died before it was properly born.

However, the SU-15A was built, and lived a turbulent life. However, this vehicle had every chance of vanishing before its completion. The GBTU suggested that the work on the «SU-85 on the SU-76 chassis» be stopped, since the SU-76M satisfied all requirements for this type of SPG.

The fate of the vehicle, now named SU-85A, was precarious indeed in June-July of 1944. A torrent of correspondence flowed between the People's Commissariat of Medium Manufacturing and the GAU. The fate of the SU-85A was decided in late July of 1944, when the chairman of the Artillery Committee, Lieutenant-General Hohlov, indicated that this direction was an important one in his letter. The GBTU gave up. An order was signed on August 2nd to perform factory trials.

By that point, the SU-85A prototype had been completed. Its mass was slightly higher than calculated, 12.2 tons. Instead of the D-5S-85, the SPG had another gun: the D-5S-85A, built at factory #8. Since the 85 mm rounds were bigger, the SPG only carried 42 of the. However, this was all relative. The SU-85, which was much larger, carried only 48 rounds. The SU-85A used a refracting TSh-15 telescopic sight, which was easier for the gunner to use. The wheel base of the experimental SPG was widened by 40 mm, and the torsion bars were thickened.

The vehicle travelled for 612 km in factory trials, 360 with a standard engine and 252 with a turbocharged one. The new engine was needed, since the mass of the SPG increased by 1.5 tons. The average speed was 30 kph on a cobblestone highway and 20.8 kph on dirt roads with the original engine. The turbocharged engine did not change the speed on a highway, but the speed on dirt roads increased to 21.3 kph. The installation of leaf springs was the correct decision. It was especially necessary at high speeds. Where the SU-85A could reach a speed of 30 kph, the SU-76M could not accelerate past 20-22 kph.

Initially, the vehicle suffered from growing pains. Some elements of the running gear had to be replaced. However, they were replaced to increase reliability, not because they broke. The exception was a splitting of a road wheel tire on the right side due to a vulcanization defect and tearing off the rivets on the front right track stop.

The next stage was proving grounds trials, which took place from September 8th to September 20th. It was planned that the vehicle would travel for 1000 km, but the actual distance was 1.5 times as much. The issue was that the right final drive broke after 570 km of travel as a result of poor thermal conditioning of the gears. Trials restarted after the repairs. As a result, the overall distance was 1570 km. 690 km was travelled on a highway, 880 more on dirt roads.

Instead of a turbocharged engine, the SU-85A used an ordinary GAZ-203. The top speed was 44.3 kph. On a highway, the average speed was 32.1 kph, and 18.4 kph on a dirt road, about the same as the SU-76M. Fuel expenditure was also within normal range: 97 L per 100 km on a highway and 169 L on dirt roads. Off-road performance was also the same as on the SU-76M.

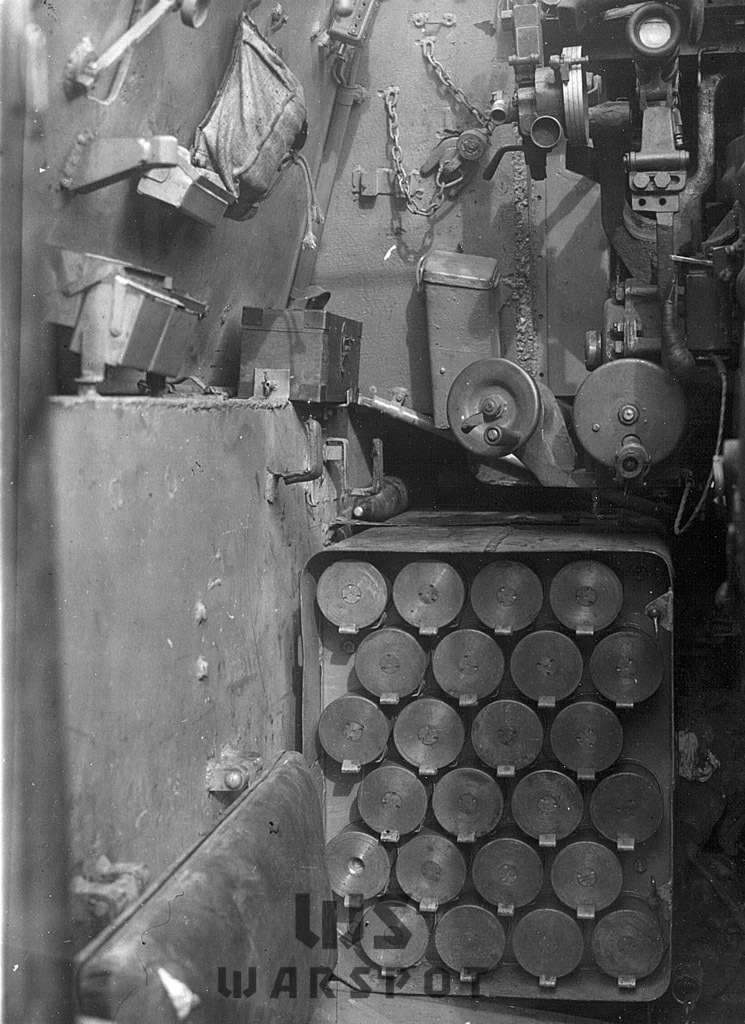

The fighting compartment was worse. The layout of the commander's station was not the best. The observation device was moved forward and up, making it hard to see to the left and the right, and impossible to look backwards. The observation slit in the front of the hull was sealed, which made it harder to see. The gunner's new workspace was much more comfortable, but due to the new layout of the ammo racks, he got in the way of the loader. The front rack (which was the main one) was positioned in front of the gunner, and the loader could not access it without his help.

The gun was also poorly balanced. Dust raised by the vehicle got inside the fighting compartment and made it impossible to work. The system to disengage the gun clamp without existing the vehicle worked poorly.

Nevertheless, the commission deemed that the SU-85A passed trials and recommended it for adoption into service. However, changes would have to be made to the gun and fighting compartment to correct the drawbacks that were revealed.

However, the GAU Artillery Committee had a different opinion. According to their conclusions made on October 31st, 1944, the SU-85A failed the trials. It was pointed out that the vehicle (called SU-85-GAZ) had a number of issues with the fighting compartment and the D-5S-85A gun. A good number of the complaints were fair. There were indeed substantial problems with firing, especially at moving targets. The vehicle was not sufficiently stable during firing. The gun also had its problems, offering excessive resistance to recoil.

The verdict was to continue work on the SPG, but launch a parallel program to develop a gun that was more suitable for such a light chassis. Astrov questioned this decision on November 5th, 1944. According to him, the issue was not with the chassis, but with the gun. Astrov called a number of conclusions made simply ridiculous. For instance, the «ineffective» firing on the move was better than what the SU-76M showed. The complaints about low precision during peak rate of fire trials also seem strange. A gun can either display peak rate of fire or peak precision at any given time. Astrov asked to re-examine the conclusions in his letter, since according to him they had a large number of mistakes. He brought «heavy artillery» with him, the GBTU USA, which was pro SU-85A.

The fighting between two organizations did not change the fact that the vehicle needed work. The D-5S-85A system that was installed in the prototype also ceased production along with the SU-85M. The second SU-85A prototype was built with the drawbacks corrected and the use of the ZIS-S-53 gun.

Meanwhile, work on the initial prototype continued. The vehicle had travelled for 2635 km by the end of 1944. The gun made 844 shots, 473 of them with increased charge. The gun was redesigned and balanced. A number of changes were made to the chassis. The casemate was fully enclosed from the rear and sides. A large rear hatch was added, but it was not very comfortable to use. The new casemate did not radically improve protection, but helped with dust getting into the fighting compartment. The commander also received a front observation device. The gunner's observation devices changed as well. The mass grew to 12.3 tons as a result.

The running gear changed too. The crown of the drive sprocket had 13 teeth instead of 15. The track stops changed. The left final drive with an increased rate of critical turns received a tubular half-axle. The rear plate was reinforced near the area where the tow hook was attached. A bracket for holding an unditching log was added.

The converted SU-85A was sent to the NIBT proving grounds in Kubinka for trials, where it was tested from January 6th to January 19th. There, it drove for 1028 km (511 on a highway, 330 on dirt roads, and 187 off-road). Even in winter conditions, performance was similar to that of the ordinary SU-76M. The increase in mass did not noticeably impact reliability. The average speeds were recorded as 29.2 kph on a highway, 22.1 kph on a dirt road, and 17.1 kph off-road. These characteristics were similar to the ones demonstrated by the SU-76M. The highest grade the SU-85A could climb was 25 degrees. After that, the tracks could not grip the frozen dirt.

Firing trials did not go as well. The Artillery Committee's complaints were well founded. The D-5S-85A gun was suitable for the SU-85, KV-85, and IS-85, but not for the light SPG. It was not easy to solve the problem with high recoil resistance. The result of firing trials was predictable. While the SU-76M and SU-85 suffered nearly no displacement in the axial plane, the SU-85A was moved back by 380-457 mm if brakes were not applied. The amplitude of oscillations was also high. The vehicle slightly turned to the left after firing. The precision remained satisfactory. The aimed rate of fire was 6 RPM, same as on the SU-85.

Firing at moving targets 1.5 km away was possible, but difficult due to issues in correcting fire. There were also issues with the gun mount. The Belleville springs deformed after 200-300 km of driving, which increased the force needed to aim it to 12-15 kg. Backlash in the aiming mechanisms was still present. Splash entered the fighting compartment as a result of firing on the gun mantlet with an MG-42.

The conclusions of the NIBT proving grounds were similar to those given previously. The SU-85A chassis was reliable, but the gun needed to be replaced. A radical change to the SPG was unavoidable.

Too late for mass production

A decision to build a second experimental SU-85A was made in late 1944, but factory management was not in a hurry to carry it out. A whole new gun needed to be designed for this SPG out of the ZIS-S-53 tank gun. In addition, the factory carefully reviewed the results of the trials at the NIBT proving grounds. There were plenty of complaints regarding the SU-85A, not just the D-5S-85A. It was clear that the SU-85A was at its end. The vehicle carrying the new gun would have to be radically different.

Work on a new vehicle began in March of 1945. However, «new' is a strong word. The SU-85A chassis was taken and merely changed. Since the end of the Great Patriotic War was drawing closer, factory management decided to save some money. Tension between the «peaceful» and «military» factions at the factory was also rising. Astrov was being given work that had nothing to do with the army. An indicator of this relationship was the drilling machine based on the GAZ-67B chassis meant for planting trees.

The SU-85 had already travelled for 4320 km since the start of its trials. The SU-85B weighed in at 12.4 tons, and thus demanded the more powerful GAZ-15B engine. The power output was 160 hp, giving 12.9 hp/ton. The power to weight ratio of the SU-76M was 12.96 hp/ton. The engine also received a T-70 style removable bulkhead. Changes were made to the transmission as well. Due to new control rods, the effort on the levers was reduced from 27 to 15 kg. Reinforcing the final drive gears increased reliability.

Another factory from Gorkiy took part in the development: factory #92. The design bureau, led by A.I. Savin, produced a number of guns, including tank guns, such as the LB-1 100 mm tank gun. The gun designed for the SU-85B was initially indexed ZIS-1s, and later received the name LB-2.

It was proposed that the gun would be based on the ZIS-S-53, but the design changed during its composition. The biggest visible change was the introduction of a single chamber muzzle brake. Its addition resulted in the gun being more noticeable when firing, but it was the lesser of two evils. Trials showed that the muzzle brake reduced the recoil resistance by 5.2-6.4 tons. Considering that excessive recoil resistance was one of the problems with the SU-85A, a reduction of nearly three fold was a significant improvement. The length of the recoil decreased to 500 mm.

The SU-85B could have ended up with a different gun. The NKV assigned work on designing an 85 mm gun for the SU-76M to the Central Artillery Design Bureau (TsAKB). In turn, they requested a production SU-76M. It is not clear what happened, but the TsAKB did design a gun in the end. This project was indexed S-68. Sadly, no blueprints survive, but judging by the description, the S-68 differed little from the SU-76M's stock gun mount. A number of changes were introduced into the casemate to house the enlarged gun. The S-68 also had a muzzle brake, but the recoil length was much greater, 900 mm. One advantage was its lighter weight. The oscillating part of the S-68 weighed 895 kg, the same part of the LB-2 weighed 1390 kg. The LB-2 was installed in a frame, but the S-68 was installed on a pintle. Instead of a TSh-15 telescopic sight, the 10T periscopic sight was planned. The S-68 was supposed to carry 40 85 mm rounds.

The project remained on paper. The GAU and GBTU rejected it in the summer of 1945, as it was inferior to the LB-2.

Like the SU-85A's gun, the LB-2 was shifted to the left. However, the shift was lesser: 125 vs 175 mm on the D-5S-85A. The sight was the same: TSh-15 refracting telescope. The gun mount and casemate were changed again. The changes were more noticeable from the rear. Instead of a short hatch, a proper door was added, which also doubled as a five round ammo rack.

The visibility also improved. The commander received a new observation device in the front of the casemate with a prism similar to the one used in the American M4A2(76)W tanks. The periscopic observation devices also changed. Finally, the complaints about the ammunition rack were taken into consideration. Out of 43 rounds of 85 mm ammunition, 24 were located in the main rack in front of the gunner. The rest lined the right side of the casemate and the rear. This improved the loader's work.

The transformation of the vehicle into the SU-85B was complete by March 28th, 1945. Factory trials followed. The vehicle travelled for 300 km between March 28th and April 5th. Its gun fired 30 shots. 70 more were made at the ANIOP proving grounds on April 7-8th. The reduced recoil resistance did its job. Now the shaking experienced during firing no longer bothered the commander and gunner. The situation with shifting aim during firing was improved. The precision was deemed satisfactory. The peak rate of fire was 11 RPM, practical aimed rate of fire was 10 RPM. The protection of the fighting compartment against frontal machinegun fire improved.

The next stage also took part at the Gorohovets proving grounds, on April 20-25th, 1945. 604 shots were made in this period and the vehicle travelled 502 km. The practical rate of fire was established to be 8-11 RPM, depending on which rack the loader used. Maximum rate of fire was measured as 12 RPM.

It turned out that, unlike the SU-85A, the SU-85B could successfully fire at moving targets at ranges of 900 meters and greater. The SU-85B also fired on the move well, although the fumes that exited the muzzle brake made it more difficult. A 20% hit rate was achieved when firing at the move and 85% from short stops. The stability when firing was 1.5-2 times greater than on the SU-85A.

The SU-85B passed trials. No serious defects were discovered. Trials that took place at the NIBT proving grounds between April 25th and May 3rd were also successful. The vehicle drove for 1004 km and fired 800 rounds. It was remarked that the SU-85B was easier to steer than the SU-76M, easier to work in, and had slightly higher speed. Even a defect in a drive sprocket did not mar its image. The SU-85B was recommended for mass production.

Discussion regarding starting production at the Molotov GAZ factory began in early April. Factory management expected it to take 1.5-2 months to prepare for production, which would mean starting to put out the SPG sometime in June. However, the Molotov GAZ factory began nothing short of a purge of «tankers» on May 9th. The SU-85B essentially died in the early summer. A report by senior military representative Okunin describes the situation in colourful words.

«This month, the composition of the tank design team continued to change. Deputy chief designer, comrade Astrov, left GAZ and moved to the position of chief designer at the KIM automobile factory. The core of tank designers left the design bureau. There are only a handful of designers left to support present production. Factory management ended all experimental work on combat vehicles. For instance, a group from factory #235 that arrived with a prototype 85 mm gun to test its installation into a SU-76 was not even permitted to enter the factory. The factory categorically refuses to continue any experimental work on SPGs.»

The visitors from factory #235 came because production of the gun for the SU-85B was planned at the factory. However, this was not a gun with a monobloc barrel. Factory #235's equipment did not allow for production of this type of barrel. The problem was solved on a third project for installation of an 85 mm gun into the SU-76M. The design bureau at factory #235 produced several guns for SPGs by March of 1945, including the 85 mm B-13. The system, designed under the supervision of K.F. Fedorenko, had similar characteristics to the LB-2, including recoil length. The project was approved, but frozen after successful trials of the LB-2. Now it was needed once more.

Trials of the SU-85B with the V-13s gun began on August 4th, 1945, and continued until September 6th. 1195 shots were fired, 550 of which had increased propellant charge. A monobloc barrel arrived at the Gorohovets proving grounds, and used to make another 424 shots. Both showed satisfactory lifespans.

However, the time was spent in vain. The GAZ did not wish to hear a word about SU-85B production. Factory #40 was slowly wrapping up production of the SU-76M. The GBTU was already dreaming of something more. Requirements for a 25 ton SPG that would be impenetrable to the 88 mm Pak 43 were composed in late 1945. It would be armed with an 85 mm gun with a muzzle velocity of 900 m/s. Presumably, a 400 hp engine was being designed at factory #40 for this SPG specifically. However, this wishlist ended up with nothing. After nearly a decade and a half, on August 6th, 1958, the Soviet Army adopted the light SU-85 SPG, most frequently known by the unofficial name ASU-85. It was designed at factory #40 under Astrov's direction.

Translated by Peter Samsonov. Read more interesting tank articles on his blog Tank Archives.

Sources:

- Central Archives of the Russian Ministry of Defence.