The Americans considered improving the firepower of the Medium Tank M4 back in September of 1941. A year later, experiments with installing the 76 mm T1 gun into the stock turret commenced. Even though the gun fit, the military was unsatisfied with this rearmament. A decision was made to equip the M4 with the turret from the Medium Tank T23, which did not enter production. This was not hard, since the turret ring diameter was the same.

Shortly before that, the M4 (known in the USSR under the nickname «Emcha») was equipped with wet ammunition racks. These modernized tanks, whose name received the suffix (76)W, went into production in January of 1944. Among them was the M4A2(76)W, the production of which began in May of 1944. The USSR received these tanks under the Lend Lease program.

Study with a time limit

Dmitriy Loza's memoirs «Commanding the Red Army’s Sherman Tanks» make it seem like the first M4A2(76)W were at the front lines in August of 1944, but that is not the case. Usually, at least several months went by between a new modification going into production and it appearing in Lend Lease shipments. The M4A2 with a 76 mm gun was no exception. Information about the upcoming arrival of Shermans armed with 76 mm guns was made available by the People's Commissariat of Foreign Trade on August 22nd, 1944.

The tanks with new guns arrived much later. The first vehicles of this type arrived in the Soviet Union through Iran in the second half of September of 1944. This can be seen in delivery reports for this time period. The problem was that the tanks were not fully equipped. For instance four tanks that arrived in Baku on the «Shubany» transport had no signal flags, or return springs and brass catchers for Browning M1919 machineguns.

According to the reports, these were the first M4 tanks with 76 mm guns to arrive in the USSR, at least by the southern route. It's possible that individual vehicles arrived with northern convoys, but accounting was less precise there. In any case, these tanks did not arrive in Gorkiy in September of 1944.

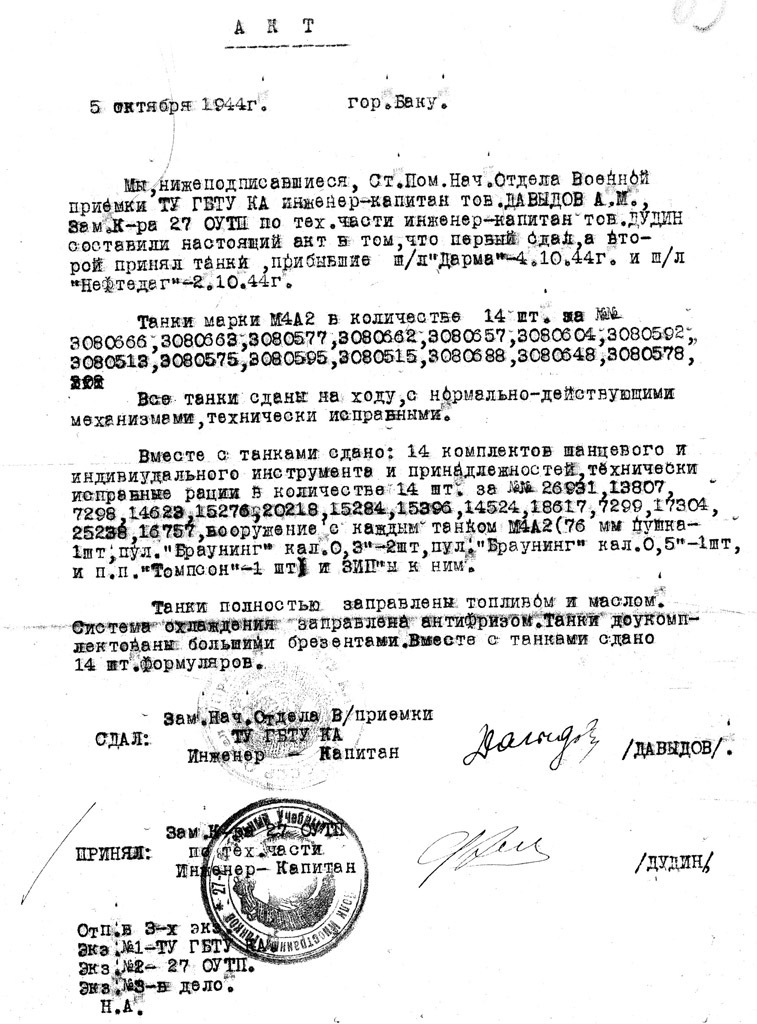

Fully fledged supplies began in October. On October 5th, the «Darma» transport brought 14 M4A2 tanks with 76 mm guns. The same number arrived with «Emba» on October 14th. In total, 131 M4A2 tanks were received in October, only 4 of which had a 75 mm gun. Tanks were sent to Gorkiy, where they were distributed to units. According to reports, Gorkiy military acceptance received 319 M4A2 tanks, which included tanks arriving by the northern and southern convoys in September. 279 M4A2 tanks were distributed into tank units from Gorkiy, including 203 with 76 mm guns. Later, the division between tanks with 75 and 76 mm guns disappears from documents, since supplies of M4A2 tanks with old guns ceased.

The new tank was not only awaited by the military, but by specialists from the NIBT Proving Grounds. By the middle of September, the Red Army GBTU received more precise information about the 76 mm guns that could be installed in the M4A2: the M1A1 and M1A2. Overall, the guns were identical, except for the rifling angle. In the M1A1, it was equal to 40 calibers, but the M1A2 had it at 32 calibers.

On September 20th, the trials program of the «76 mm gun installed on the American M4A2 tank» was completed. According to it, the muzzle velocity of the shell and other data would be obtained. 182 shots were planned, 131 with armour piercing shells and 51 with HE shells. The plan also included studying the compatibility of ammunition for the gun of the M4A2 and the GMC T70, which was tested at the proving grounds prior to that. The ability to use domestic ammunition was also tested, with an emphasis on subcaliber and HEAT ammunition. 5 days were allotted for trials.

The testers had to wait for weeks for a tank to be assigned to them. The tank with registration number U.S.A. 3080832 was only selected for the NIBT Proving Grounds by the Gorkiy Military Acceptance on October 7th. This was only the beginning of problems with initial plans. Instead of testing the gun, the proving grounds specialists were given a different task: the composition of a technical description of the new tank. It was ready by November 14th, 1944.

According to the specialists, this was the fourth modification of the tank. The second variant was the M4A2 with a telescopic sight, «wet» crankcases, applique armour on the sides, a new oil filter, and ammunition capacity reduced to 85 rounds. The testers estimated that these tanks were received by the USSR closer towards the end of 1943. The third modification, according to the description, was the M4A2(75) with an altered hull, but without a wet ammo rack, which was introduced later.

The description was not very in-depth, which led to a scandal in December of 1944. A number of mistakes were made, including ones connected with the parking brake. The thickness of additional armour on the sides was evaluated as 25 mm instead of 38 mm. The purpose of the armour was also incorrectly stated: it was there to protect the crew, as well as the ammunition. The proving grounds staff also missed the fact that the turret basket was gone. The overall verdict was that the technical description had to be composed anew.

Study of the new tank was not going according to plan. Instead of Kubinka, the task was assigned to the Gorohovets ANIOP. A new tank with registration number U.S.A. 3081179 was also sent there. Gunnery trials were not performed, since it was clear that there was not much of a difference between the guns used on the M4A2, GMC M10, and GMC T70. A technical description of the gun was composed, as well as a guide with differences in its service.

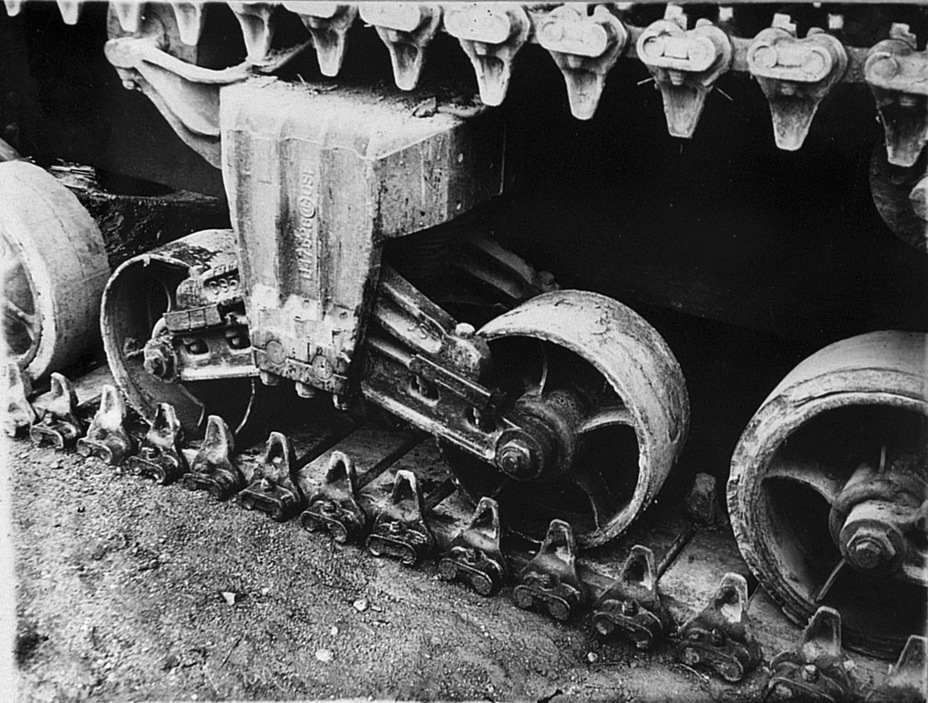

It's worth mentioning that the tank that arrived at the ANIOP was somewhat different from the one that arrived in Kubinka. The former had T54E1 track links, with chevron type cleats. The second one had the earlier T49 track links, with three bar cleats per track link.

More than a new gun

The dismissive reaction on behalf of the NIBT Proving Grounds staff was caused by an overload with work. They had to simultaneously study and test a large number of vehicles. Suffice it to say that trials of the British Cromwell IV and German Tiger II were going on at the same time. Romanian and Hungarian tanks were also being studied. Compared to this, the description of the M4A2 with a 76 mm gun (as it was often called in the report, «M4A2-76 mm») was routine.

Another piece of evidence was the length of the second study of the tank, which lasted from early 1945 to the end of July. By the time that trials were coming to and end, superior M4A2E8 tanks began arriving in the USSR. The lengthy trials were connected with the fact that instructions were given from the top to perform a full set of reliability trials. The tank would not just be studied, but thoroughly tested. Such a radical change in requirements had a reason behind it: the mass of the tank increased from 30.9 tons to 34.1, which had to have an impact on mobility and reliability.

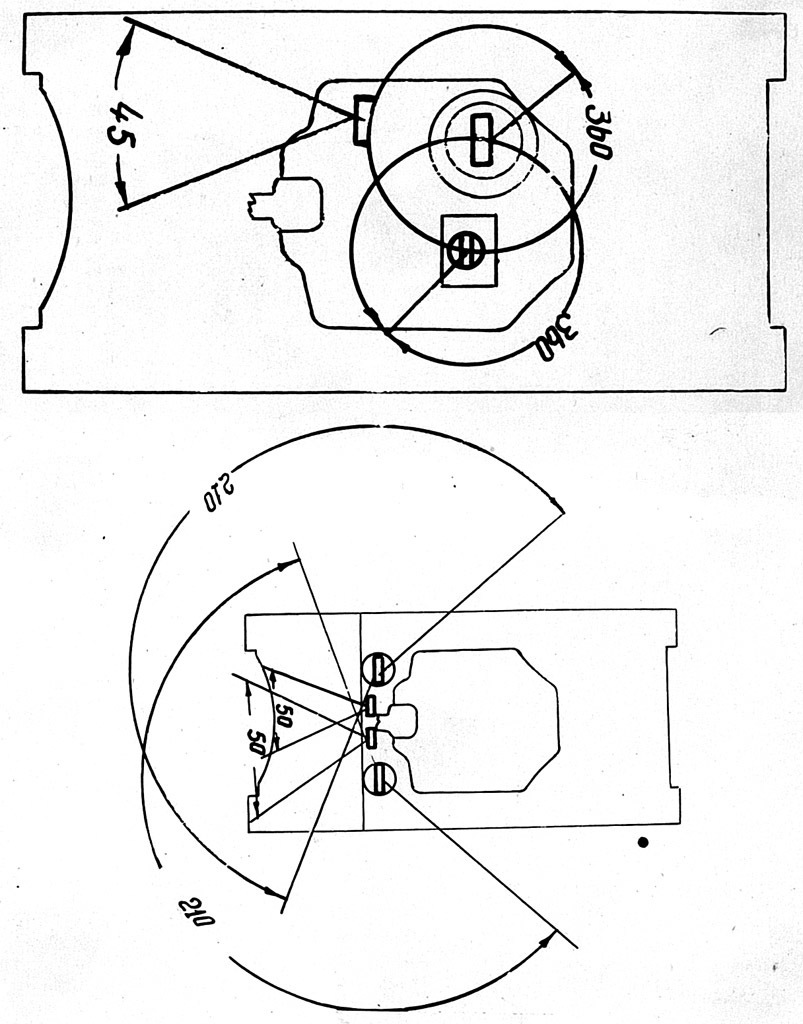

The GBTU was interested in other aspects of the tank, in addition to its increased mass. As with the T-34-85, the tank was not simply an old tank with a new gun. The tank had a completely new turret, which had a number of features aside from its increased size. For example, the D82183 commander's cupola interested the specialists so much, that a separate report was prepared about it in late December of 1944. Each observation device provided 145 degrees of horizontal range and 90 degrees of vertical range. The conclusion of the report illustrates how much Soviet specialists like the cupola.

«1. Recommend the installation of the commander's cupola of the modernized American M4A2 tank into domestic tanks, as it is the most suitable for modern tactical-technical requirements for commander's cupolas on tanks.

2. The inner and outer dimensions of the cupola allow it to be used on T-34 and IS tanks."

Even though the cupola did not directly migrate to our tanks, its design had an impact on domestic tank design. This is especially true of the observation devices, which granted good visibility. One prototype of the IS-7 used an almost direct copy, they were also used on the BTR-152.

The overall visibility from the modernized American tank was good. In addition to two periscopes installed in the roof of the driver's compartment, there as also another periscope in the hatches of the driver and assistant driver. The dead zone when looking forward was only 6 meters, which is not a lot for a tank. In addition, the seats could be elevated, and the driver could look out of his hatch while driving. The gunner and loader, also equipped with observation devices, could also see well.

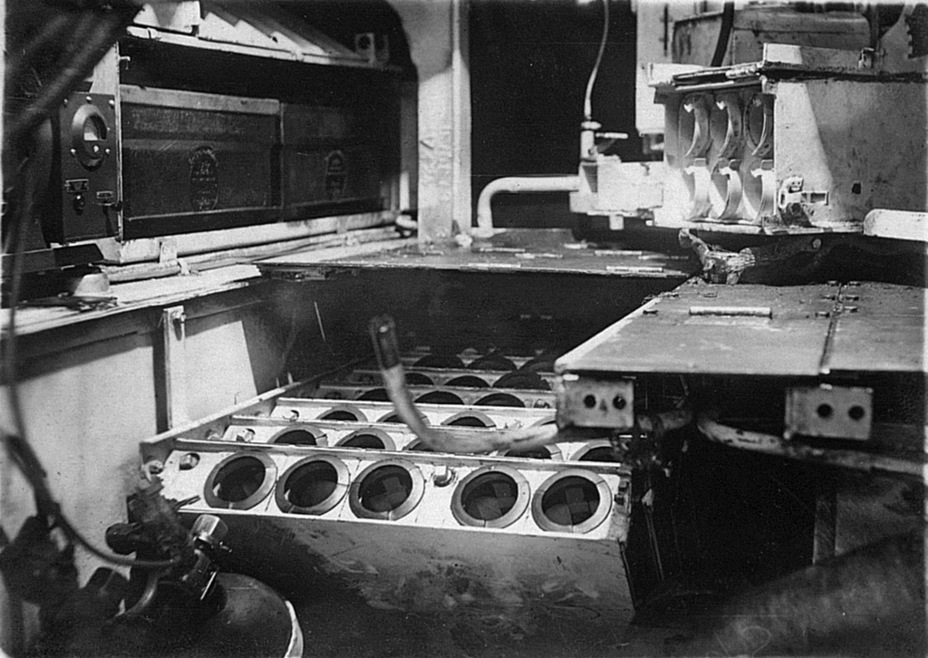

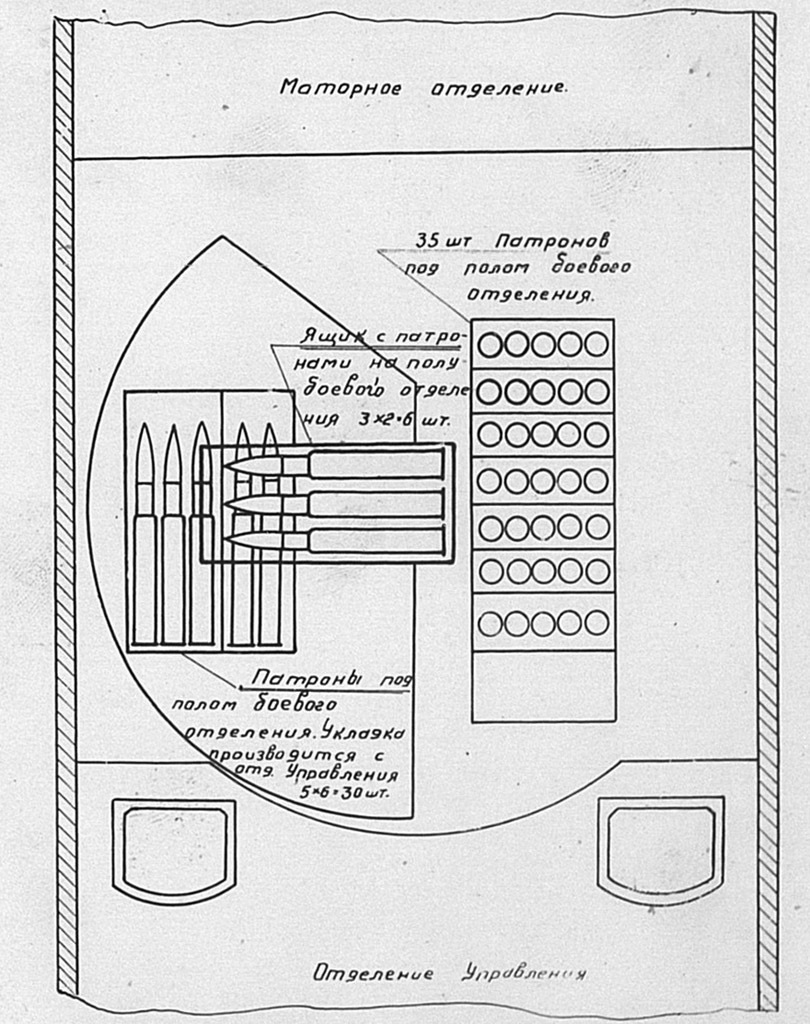

The layout of ammunition inside of the tank was also given a thorough description. The ammunition capacity decreased to 71 shells. Of them, six were located in a rack on the floor, and were used up first. The rest of the ammunition was stored in cassettes underneath the turret floor. On the right side, 35 rounds were held in slanted cassettes of 5 each, and it was easier for the assistant driver to reach them. Another 30 rounds were stored to the left, the loader's main rack. The ammunition racks were called «wet» because there were special containers in between the racks, filled with water in the summer and antifreeze in the winter. This reduced the odds of ammunition detonation when hit by an enemy shell.

The NIBT specialists had split opinions about the rack. On one hand, moving the ammunition from the sides of the fighting compartment to the floor, as well as the wet ammo rack, made it less vulnerable to enemy shells. The racks were also simple and more convenient to use. On the other hand, it became very difficult to use the racks at certain turret positions, and the assistant driver had to be distracted from his job to help load from the right racks.

Either way, this rack forced the American engineers to discard the turret basket. This was an advantage, since the sides of the basket could serve as a deadly trap for crewmen that were unable to get out of a knocked out tank. The testers considered this an advantage of the new design.

As mentioned above, the tank's trials program was changed significantly. This was caused by the fact that the GBTU decided to test the reliability of the tank, claimed by the manufacturer at 300 engine-hours or 2000 km. The trials would span for 3000 km, 100 on a highway, 1700 on dirt roads in winter conditions, and the remaining 1200 on dirt roads in the summer.

The trials also measured the top speed of the tank, pegged at 51.4 kph, or even more than the claimed top speed (48 kph). To compare, the M4A2 on rubber-metallic tracks reached 50 kph in the summer of 1943. The average speed of the tank on a highway was 26 kph, and the fuel expenditure was 330 L per 100 km. This was twice as much as a regular M4A2, but it could be explained by difficult road conditions. That also explained the low average speed, which was 39.7 kph on a regular M4A2.

This explanation is confirmed by the data gathered on dirt roads. For the M4A2, the average speed was 20 kph and fuel consumption was 246 L in the summer. In the winter, this was 22.4 kph and 268 L, respectively. As for the M4A2(76)W, its average speed was 19.2 kph in the spring, and 15.8 kph in the winter, on a dirt road covered in up to 0.8 m of snow. Considering the terrain, this is decent performance. Fuel expenditure was 371 L for 100 km in the winter, and 410 L in the spring. As you can see, there was not much difference between the highway and dirt road.

The trials program also included climbing hills. In the winter, a 22 degree slope stopped the American tank. In the summer, it managed to climb a 26 degree slope. The tank could drive while tilted up to 12 degrees in the winter, and 20 degrees in the summer. The limiting factor was often the T49 track links, which did not grip the ground well. The double differential turning mechanism also resulted in slipping. Trials in towing a T-34-85 showed that the M4A2(76)W could tow it in second or third gear with an average speed of 9.5 kph, but the fuel consumption increased to 490 L per 100 km.

The reliability of the tank was in line with the claimed values. However, trials did not go without incident. The right engine broke down on the 949th kilometer. This happened because the engine was heavily tasked: the tank was driving along a dirt road covered with heavy snow. The second engine worked for 2126 km, after which it needed minor repairs. The suspension also had problems. Road wheel rims began breaking up starting with the 1339th kilometer, mainly the ones in the rear part of the tank. The track links were much more reliable: it took until 3120 km before tearing became common. The drive sprocket crowns and springs also needed replacing.

Overall, the trials showed that the American tank's reliability was not any worse after modernization, with the exception of some suspension elements. On the other hand, the more powerful gun radically increased the effectiveness of the new tank on the battlefield. To compare, the 75 mm gun could penetrate the side of a Tiger tank from 500 meters. The improved gun could do it from 2.5 km. Improved visibility also helped. Gunnery trials showed that the gun has high precision and accuracy. The testers also liked the hydraulic turret traverse. The gyroscopic stabilizer improved the gun's precision on the move at a speed of 15 kph by 2 times, and 5-6 times at a speed of 25 kph. The modernization was a success.

Workhorse of the last year of the war

Even though real supplies of M4A2(76)W tanks only began on October of 1944, this tank was the most numerous type supplied under the Lend Lease program. According to American data, 2095 tanks with 76 mm guns were sent to the USSR, a little higher than half of all M4A2 tanks sent, and more than 2/3 of all M4A2(76)W tanks. However, this number includes M4A2E8 tanks, which began arriving in April of 1945. They deserve a separate article.

The first Soviet unit to receive the new tanks was the 27th Independent Tank Training Regiment, located in Baku. It encountered the same issue that units with M10 tank destroyers: a shortage of shells. A telegram sent on September 30th, 1944 by the regimental commander, Lieutenant-Colonel Vylegzhanin, demanded shells for his tanks. On October 28th, the regiment received 19,277 HE and 6952 AP shells. Clearly, this was not enough to solve the issues, since another large order followed in December. Each tank needed 10 ammunition loads, 80% of which must be HE. It was noted that there were no reserves at the front or in warehouses.

It's possible that this was the real cause for investigating the possibility of using domestic ammunition. The shortage caused the removal of gunnery trials from the trials program. The issue was solved quickly, and 33,920 shells were shipped to Murmansk in December, 22,044 HE and 11,876 AP.

There were also instances of not fully equipped tanks. For example, 10 tanks that arrived in Gorkiy had to be equipped with Soviet radio stations. Another 8 tanks came in November with no sights. These incomplete deliveries happened in December, and in 1945. A frequent defect was the breakdown of the lock on the driver and assistant driver's hatches. 4 cases of wounds due to this breakdown were recorded in Baku.

Another issue was rather unusual. Due to the long barrel, the gun was turned backwards 180 degrees during transport. There was no rear travel lock, which caused the elevation mechanism gears to break.

A known issue of the M4A2 was the poor traction between the tracks and the ground. This issue cropped up more often in the winter. For this reason, tanks that went through the 27th training regiment received additional cleats, welded onto every fifth track link. This modernization was applied starting in November of 1944.

The first 76 mm M4A2s were sent to the 1st Mechanized Corps. The deliveries began in October and continued into November. The corps, commanded by Lieutenant-General S.M. Krivoshein, was a part of the 2nd Tank Army (starting with November 20th, 2nd Guards Tank Army) of the 1st Belorussian Front. By the start of the Vistula-Oder offensive, the 1st MC had 175 M4A2 tanks, all in working order. The measures taken to equip units with ammunition had an effect: on average, there were 1.5 ammunition loads available per tank.

The 8th Guards Tanks Corps, a part of the 2nd Belorussian Front, had even more M4A2s. As of January 14th, 1945, it had 185 of these tanks. The tanks were also a part of the 9th Guards Mechanized Corps from the 2nd Ukrainian Front. All of these units retained «ordinary» M4A2 tanks with 75 mm guns.

New American tanks took an active part in the fighting of winter-spring of 1945. The fact that these battles happened in much better road conditions was a definite plus. In situations where it wasn't necessary to drive through snowbanks or mud, the high reliability of American tanks made a difference.

The tanks of the 1st Guards Mechanized Corps were the first to enter Vienna. M4A2 tanks from the 1st Mechanized Corps also played an important part, encircling the ring around Berlin from the northwest. American tanks also took part in the liberation of Prague. The 9th Guards Mechanized Corps excelled here. The war was not over for the tanks in this unit, as the M4A2 tanks from 9th Guards MC fought against Japan.

The M4A2(76)W was the best tank out of all of those that were delivered to the USSR in large numbers under the Lend Lease program. Its characteristics were comparable to those of the T-34-85, making it a very modern tank.

Unfortunately, time did not spare them, and until recently, not a single complete tank of this type was known. However, misfortune sometimes turns to fortune. On March 20th, 1945, a German torpedo fired by U-968 sank the SS Thomas Donaldson, a part of convoy JW-65. It sank near the island of Kildin, just a little bit short of Murmansk. The transport sank at a small depth, only 60 meters. In 2014, the first M4A2(76) was recovered, and another tank was recovered in 2016. These are likely not the last tanks to come from SS Thomas Donaldson.

Translated by Peter Samsonov. Read more interesting tank articles on his blog Tank Archives.

Sources:

- Central Archives of the Russian Ministry of Defence;

- Russian State Archive of Film and Photo Documents.