In December of 1936, the German military signed a contract with the Krupp conglomerate for a batch of 35 Begleitwagen tanks. This tank was designed to fight as a direct fire support tank, as its name suggests. The tank's main targets were going to be enemy infantry and light fortifications. Ironically, this vehicle became Germany's most numerous medium tank by the start of WWII. Later, the PzIII became more numerous, but only for a short time. By 1943, the Begleitwagen, known as the PzIV, retook the lead. The Pz.Kpfw. IV was the only German pre-war tank that never went through a radical chassis modernization.

Many Small Improvements

The contract didn't mean that the B.W. I Kp would go into production without changes. Trials showed that many small improvements had to be made to the entire design. This is a perfectly normal situation; history knows few cases where a mass production tank did not differ from its prototype. However, the B.W. I Kp had no major differences from the production tank. The overall concept of the tank proved successful and did not require serious changes.

Despite a lack of major changed, 1.Serie/B.W. officially indexed Pz.Kpfw. IV Ausf. A, retained only 7 components that were completely unchanged. Among them were the radiator, engine compartment bulkhead, brakes, and transmission elements. Everything else had to be changed in one way or another by Krupp engineers.

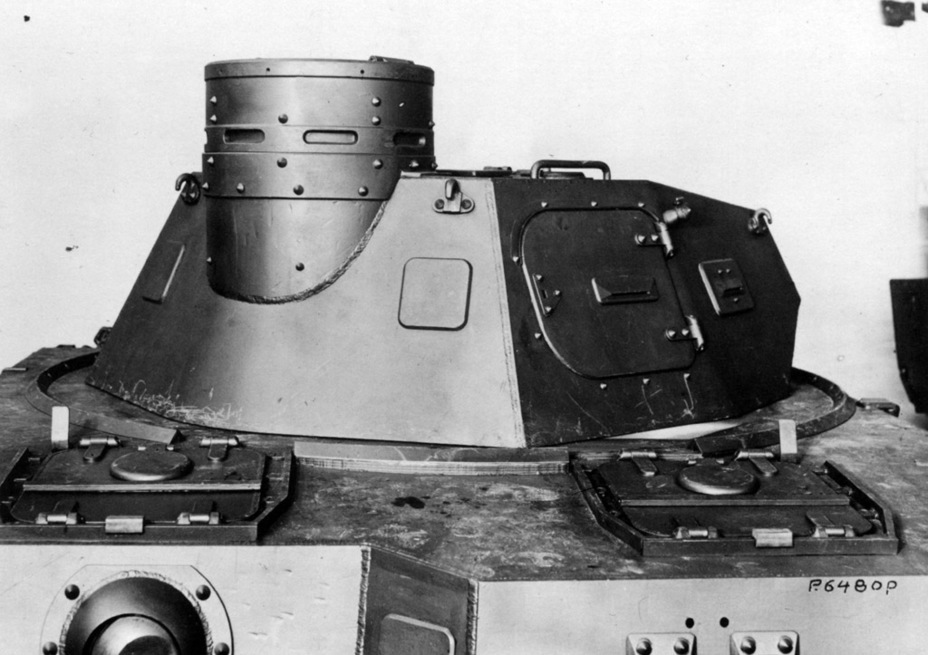

Usually, the problem wasn't that the old components were bad, but that new ones were easier to produce. One example is the turret. The B.W. I Kp turret had many riveted connections that were replaced with welds on the production turret. Rivets were left only on the hatch hinges and the commander's cupola. The cupola was replaced with the one from the PzIII Ausf. B, which was also designed by Krupp engineers.

The hull was also slightly changed. It's worth pointing out new observation devices, taken from the PzII Ausf A. The armour was left at the level of the B.W. I Kp and protected only from rifle bullets. The floor was reinforced slightly. Most of the changes to the design were aimed at making the crew's job easier.

There were many more changes inside the tank. Instead of the 10 L Maybach HL 100, mass production tanks used the 10.8 L Maybach HL 108 TR 230 hp engine. The tank also received a ZF SFG 75 gearbox. The new engine raised the maximum speed of the 18 ton tank to 32.5 kph. This wasn't a lot, but enough for a support tank. The running gear was also changed a little. The drive sprockets and idlers were altered.

The first two PzIV Ausf. A tanks with serial numbers 80101 and 80102 were received by the customer on November 29th, 1937. By December there were already new design changes after specialists from the 6th Waffenampt studied the tanks. In his report, Engineer-Senior Lieutenant Olbrich lists 30 defects, some of which Krupp engineers disagreed with. Nevertheless, the ammunition capacity was reduced from 140 to 122 shells, which required a redesign of the ammunition racks.

Due to various changes, the departure of the first PzIV Ausf. A tanks to the army dragged on. In February, the AA machinegun mount, initially attached to the left side of the turret platform, was removed. The design was inconvenient: you could only fire while standing on the ground, and the range of movement was very limited.

There is an interesting story with the last few tanks from the 1.Serie/B.W. On January 31st, 1938, the Grusonwerk factory that was building these tanks reported that the subcontractors building hulls, Harkort & Eicken GmbH and Eisen- und Hüttenwerke AG, were behind schedule. Meanwhile, preparations were underway at Magdeburg to begin production of 2.Serie/B.W., or PzIV Ausf. B. The solution was simple: the last five 1.Serie/B.W. tanks were built with 2.Serie/B.W. hulls.

The last tanks built at Grusonwerk had new hulls, but old turret platforms and turrets. For example, tank #80134 had hull #80206. The result was a comical situation where the hull could protect the tank from 20 mm cannons and high caliber machineguns, but the turret could only withstand rifle bullets.

Machinegun, begone!

The Spanish Civil War, where the Germans were actively supporting the rebels, made a series of changes in German tank building. It turned out that 14.5 mm of armour was not enough for modern war. According to the Germans, the main enemies of tanks were high caliber machineguns and autocannons. The fact that both sides actively used 37-45 mm anti-tank artillery slipped by them. Nevertheless, the requirements for tank armour changed in 1937.

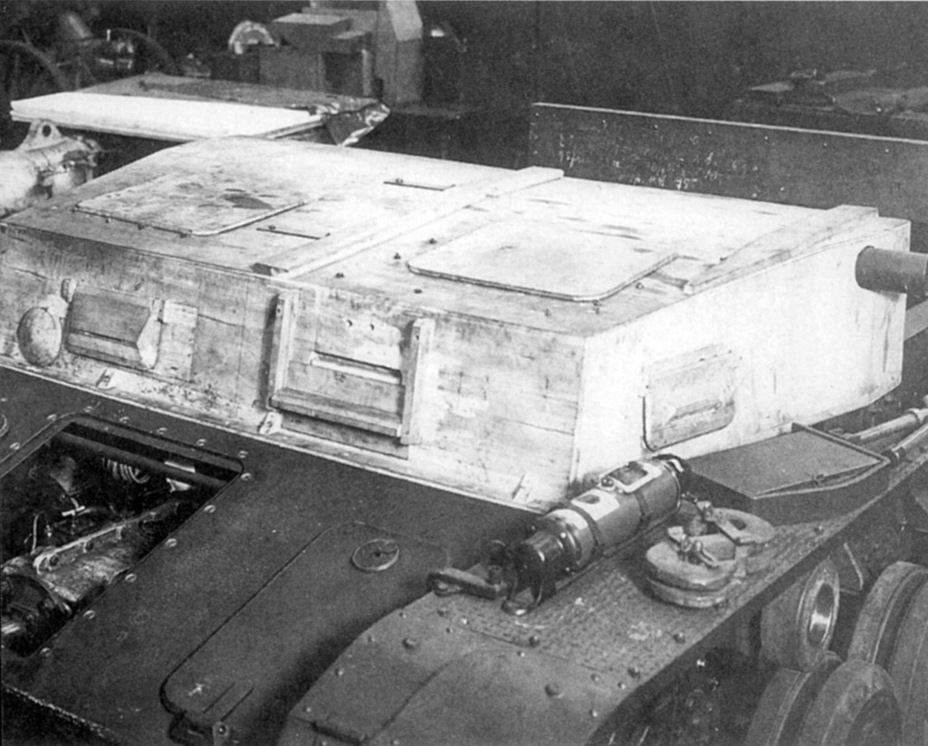

In October of 1937, Grusonwerk received a contract to built 42 2.Serie/B.W. tanks (PzIV Ausf. B). The turret platform for this tank was tested on the B.W. II Kp. Due the improvement of the front armour to 30 mm, it was decided that the hull machinegun would be removed. Instead, the radio operator received an observation port and a pistol port to the right, as well as an MP-38 submachinegun. The 6th Waffenprüfamt considered this a small price to pay for thicker front armour. The central front plate was also thickened to 30 mm, the upper and lower parts to 20 mm. The side armour was untouched. The driver received an improved observation device.

The turret changed along with the hull. The removable gun mantlet had to be deleted, and the gun armouring changed slightly. The pistol ports were redesigned and were not more resistant. The tank received a new, significantly more protected, commander's cupola. As with the hull, the thickness of the turret armour was increased to 30 mm.

The changes didn't stop at armour. The Maybach HL 108 TR turned out too weak, and it was replaced by the 265 hp Maybach HL 120 TR, which later became the most numerous German tank engine. Working with the ZF ZZG 76 transmission, the 12 L engine accelerated the tank to 42 kph. The ammunition capacity of the 7.5 KwK L/24 was reduced to 80 shells. This was partially motivated by an aim to «slim down» the tank (the changes increased its mass by half a ton), but there were other reasons. It turned out that shells from the large 40-shell ready rack had a tendency to fall out, which was rather unsafe.

The first PzIV Ausf. B (serial numbers 80201-80242) were received by the customer in May of 1938. Interestingly enough, these tanks used hulls from PzIV Ausf. A tanks. This was the consequence of the aforementioned hull switch. Now the situation was reversed: the turret and turret platform could resist 20 mm guns, but the hull was vulnerable.

In September, another complaint came from Magdeburg that subcontractors are taking their time with the hulls. This time, the contract was changed. Harkort & Eicken GmbH built hulls numbering 80213-80224 and Eisen- und Hüttenwerke AG built hulls 80225–80242. These hulls wren't used on the PzIV Ausf. B. Instead, tanks with serial numbers 80213–80242 received hulls 80301–80330, which were meant for the PzIV Ausf. C. The armour mix-up was avoided, as both modifications had identical armour. The last PzIV Ausf. B tanks were delivered in October of 1938.

Production of 3.Serie/B.W. (PzIV Ausf. C) tanks could not have happened at all. In early 1937, Heinrich Kniepkamp decided to standardize German medium tanks, leaving just one out of the two. The idea was not without merit: Germany had two medium tanks, similar in characteristics, and differing mostly in armament.

Kniepkamp's plan involved installing the B.W. turret on the 4.Serie/Z.W., the future PzIII Ausf. E. In June of 1937, Krupp was informed that 2.Serie/B.W. would be the last batch of the PzIV. Here is when the excellent plan shattered on harsh reality.

The experimental prototype of the 4.Serie/Z.W. was only sent to Kummersdorf in the spring of 1938. Erich Wolfert, Krupp's chief engineer, raised a protest. The medium tank production quotas would not be met, and it was impossible to wait any further.

As it turned out later, Wolfert was right. The PzIII only passed the ten tanks per month mark in July of 1939, and proper mass production began in October, after the start of the war. In these conditions, the only reasonable option was to keep producing the PzIV. Nevertheless, Krupp managed to get the 3.Serie/B.W. approved much earlier, in October of 1937.

The PzIV Ausf. C (serial numbers 80301–80440) was similar to its predecessor. The biggest external change was the armour of the coaxial machinegun. Other changes include altered locks on the engine compartment roof and altered ventilation on the turret roof.

New changes were introduced in production. Starting with tank #80331, Ausf. C tanks were equipped with the same commander's cupolas as the PzIII Ausf. E, and starting with tank #80341, a modernized Maybach HL 120 TRM with improved ignition. The 58th turret platform and onward had special visors above the driver's observation devices.

The first PzIV Ausf. C were produced in October of 1938, with 30 tanks receiving 2.Serie/B.W. hulls. The production rate was quick, especially when compared to the PzIII. The last 10 tanks were completed at Grusonwerk in August of 1939, and production of the PzIV paused for a month.

Out of 140 3.Serie/B.W. vehicles, 134 were built as tanks. In February of 1939, Krupp sent 6 chassis (80435–80440) to the 5th Waffenprüfamt, which used them to build Bruckenleger IV bridgelayers (same as what the B.W. II Kp was converted into). The Magirus company made the conversions. Trials showed that the designs were flawed. Later, two chassis (80435 and 80438) were used for experiments. The remaining bridgelayers were converted back to tanks and sent to the army.

These weren't exactly ordinary tanks. Since turret platforms of tanks ##80436, 80437 and 80439 were already used for bridgelaying equipment, they had to be replaced. Since this was already in June-July of 1940, there were no spare 3.Serie/B.W. turret platforms. The result was another hybrid with PzIV Ausf. C turrets and chassis and PzIV Ausf. E turret platforms.

First Time's the Charm

Various changes to improve combat effectiveness and ease the crew's jobs were made to the tanks almost as soon as they entered the army. One of the first changes was the appearance of smoke grenade launchers in August of 1938. They were installed in the rear of the tank. The launchers began appearing on the PzIV Ausf. B as standard equipment, but tanks built earlier only received them in the army.

Another piece of equipment added by the army was a special railing that was installed on the gun. The issue was that there was a serious risk of shooting off your own antenna with cannon or machinegun fire, as it was not always lowered in combat. This issue was known to Krupp even when the first B.W. was undergoing trials, but initially there was no solution for it.

It's worth noting that far from all tanks received this guard. There are photographs of tanks (both in peacetime and in combat) that do not have them. Using prior experience, an improved guard with a complicated, yet effective, shape was introduced on the PzIV Ausf. C. The PzIV met the start of the war in this modification.

Due to the delays in the Z.W. program, only 51 PzIII tanks were among the units that entered Poland on September 1st, 1939. Out of 211 «support tanks», 198 were in Poland, or almost four times as many as the tank they were supposed to support. It's not surprising that in January of 1939, the structure of a light tank battalion included 8 PzI tanks, 6 PzIVs, and only 3 PzIIIs. The medium tank battalion structure looked even stranger, 5 PzIII and 14 PzIV. Due to a lack of PzIV tanks, their number in light tank battalions was lowered to 3-5 in practice.

Overall, these «support tanks» became the best German tanks in the Polish campaign. Good mobility was combined with the firepower of a 75 mm gun. The idea of increasing the armour to 30 mm was correct.

However, it appears that the Germans did not learn their lesson from the fighting in Poland. It turned out that the Polish army was armed with 37 mm wz.36 anti-tank cannons, a licensed version of the Swedish Bofors Infanterikanon M/34. This gun made its debut in Spain, and by the start of WWII, Poland had about 1000 of them. 30 mm of armour proved no trouble for the gun, and it could be penetrated from over half a kilometer away.

The 6th Waffenprüfamt also underestimated the chances of a tank being hit in the side. A 20 mm autocannon destroyed the PzIV tank commanded by Wiktor IV Albrecht on September 18th, 1939. Sergeant Roman Orlik's TK-S tankette with a 20 mm gun shot the tank in the side, which detonated its ammunition. These cases were far from extraordinary. In total, the Germans lost around 20 PzIVs irreparably.

It's worth focusing on the ammunition rack detonation closely. One of the PzIV's main problems was that its ammunition racks were located around the entire perimeter of the fighting compartment. It was difficult to avoid hitting the ammunition. Since most of the tank's shells were of the high explosive variety, the odds of detonation were high. Because of this, the PzIV is the uncontested leader in the gloomy parade of destroyed German tanks. Flying turrets, frequently detached from the hull along with the turret platform, were a common sight.

Despite the widespread use of anti-tank guns by the Poles, the only change made to the PzIV by the Germans was the increase of the side armour to 20 mm on the PzIV Ausf. D. May of 1940 was sobering as it suddenly turned out the the French also have anti-tank guns, thousands of them, and 30 mm of armour was no great obstacle.

In addition, the cannons of German tanks were powerless against the Char B1 bis, and the PzIV clashed with it many times. Even after this experience, the question of improving armour moved to the practical stage only in early 1941.

Even then, no deep modernization of the pre-war PzIV was made. Some tanks received additional 30 mm of armour in the central front plate, increasing it to 60 mm, but leaving the front of the turret platform and turret at 30 mm, despite a high percentage of shots hitting those parts. Armoured in this fashion, PzIV tanks were sent first to the Balkans, then the Eastern Front.

After 1941, pre-war production PzIV tanks were sent to training units. Some amount of them ended up in the 21st Tank Division, located in Normandy. That is where they last saw battle. Unfortunately, not a single pre-war «support tank» survived to this day.

Overall, one can safely say that Krupp made a good tank. Yes, there were some complications in production. However, even at the start of its mass production, the tank had significantly fewer growing pains than other German tanks. Nobody in the 6th Waffenprüfamt could guess that the «niche» tank would end up outliving not only other pre-war tanks, but several tanks that were designed during WWII.

Translated by Peter Samsonov. Read more interesting tank articles on his blog Tank Archives.

Sources:

- Panzer Tracts No.4 Panzerkampfwagen IV, Thomas L. Jentz, Hilary Louis Doyle, Darlington Publication, 1997, ISBN 0–9648793–4–4

- PzKpfw IV and its Variants 1935–1945. Book 2, Walter J. Spielberger, Thomas L. Jentz, Hilary Louis Doyle, Schiffer Publishing, 2011, ISBN 978–0–7643–3756–7

- Author's photo archive