The StuG III and StuG 40 were the most numerous armoured vehicles in the German army during WWII. Together with the StuH 42 assault howitzer, 11,300 such vehicles were built. The front lines needed more of these assault guns, and so Germany began to develop these vehicles on other chassis. The fighting in 1942-43 made it clear that the Marder tank destroyers needed to be replaced. The Wehrmacht wanted something lower and better protected. This began the development of the Jagdpanzer IV tank destroyer. The sum total of its characteristics made this vehicle the best German medium tank destroyer of the war.

An alternative from VOMAG

The StuG did not become common immediately. These vehicles were primarily meant for infantry support and went to artillery units, not tank ones. The StuG could be considered a «budget» Pz.Kpfw.IV : the tank without armament cost 103,500 Reichsmarks, while the StuG without armament cost 82,500.

The situation changed in late 1942. The 7.5 cm StuK 40 L/43 made the StuG an effective countermeasure to Soviet tanks, even the well protected KV-1. Later the 48 caliber version was developed. In late 1942 the monthly production rate of StuGs finally surpassed 100 vehicles, and in December of 1942 the most numerous vehicle in the history of German armour came to life: the StuG 40 Ausf.G. MIAG joined Alkett in producing the StuG 40 in February of 1943. Together, these two companies produced as many as 300-350 StuGs per month.

The Pz.Kpfw.IV received a similar long barrelled 7.5 cm KwK 40 L/43 gun as the StuG. Unlike the Pz.Kpfw.III Ausf.K, which remained on paper, the Pz.Kpfw.IV with long guns went into production. The first tanks of this type called Pz.Kpfw.IV Ausf.F2 were built in March of 1942. In July they were renamed Pz.Kpfw.IV Ausf.G. 1927 Pz.Kpfw.IV Ausf.G were built until June of 1943.

The increase in Pz.Kpfw.IV production took place even before such an increase with the StuG. In addition to Grusonwerk, VOMAG began building the Pz.Kpfw.IV Ausf.F in August of 1941, and the Austrian Nibelungenwerk company joined in during November of 1941. The latter was built especially to produce the Pz.Kpfw.IV, and in June of 1944 it turned out to be the only factory still making this tank. VOMAG (Die Vogtländische Maschinenfabrik AG) was a major producer of trucks and buses before the war.

VOMAG never built tanks until 1941, but in 1942 they completely stopped building trucks. This allowed the factory to double its output in tanks by 1943.

By September of 1942 the armour of armoured vehicles needed to be increased as well as the armament. One of the consequences of this was the development of the Pz.Kpfw.IV Ausf.H or the 9.Serie/B.W. This tank was supposed to get sloped front and side armour, but the idea had to be discarded as the mass of the modernized tank increased to 28.2 tons. The idea of installing the 75 mm KwK 42 L/70 into the turret also ended up failure.

The work on improving the characteristics of SPGs went on in parallel. An SPG with the L/70 gun on the chassis of the Gefechtsaufklärer Leopard was developed in the fall-winter of 1942. Alkett received an order for modernization of the StuG III in December of 1942. The new StuG would have a 7.5 cm KwK 42 L/70 gun and sloped casemate armour. This work only reached the full sized model stage, completed in 1943. Later the work was applied to the Jagdpanzer 38 project.

Only VOMAG reached the prototype stage. The requirements they received were similar to those received by Alkett, the only difference is that the Pz.Kpfw.IV Ausf.F was used as a chassis. The SPG initially used an L/70 gun, but the requirements later changed. Such a long gun would have inevitably overloaded the front wheels, as happened later with the Panzer IV/70.

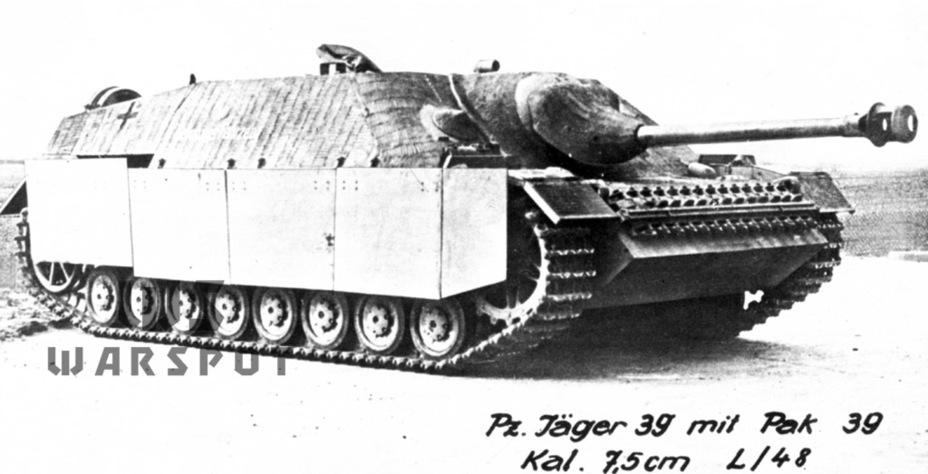

The final requirements listed the 7.5 cm Pak 39 L/48. This gun was a 7.5 cm StuK 40 L/48 with a different mounting. The StuG's gun was installed on a pedestal mount, while the 7.5 cm Pak 39 L/48 was held on a frame. This reduced the mass of the system and improved protection. The frame allowed the designers to get rid of the bulges in the casemate that were a big weakness of the StuG.

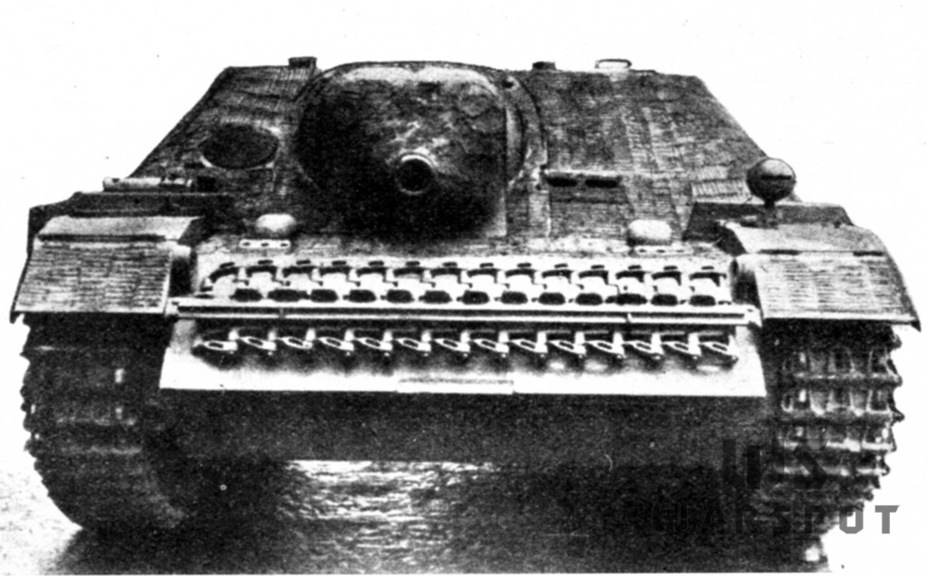

The casemate turned out to be rather original. The sides were sloped in addition to the front. The front armour, sloped at 40 degrees, provided the equivalent of 110 mm of protection at 90 degrees. The sides installed at 60 degrees were 40 mm thick. Unlike the StuG, the width of the casemate was equal to the width of the entire vehicle. The sponsons were used to store ammunition, as a result of which the SPG fit 79 75 mm rounds.

The rational layout resulted in the SPG being lower than the StuG, which was not that tall to begin with. The kleine Panzerjäger der Firma VOMAG was only 1.7 meters tall.

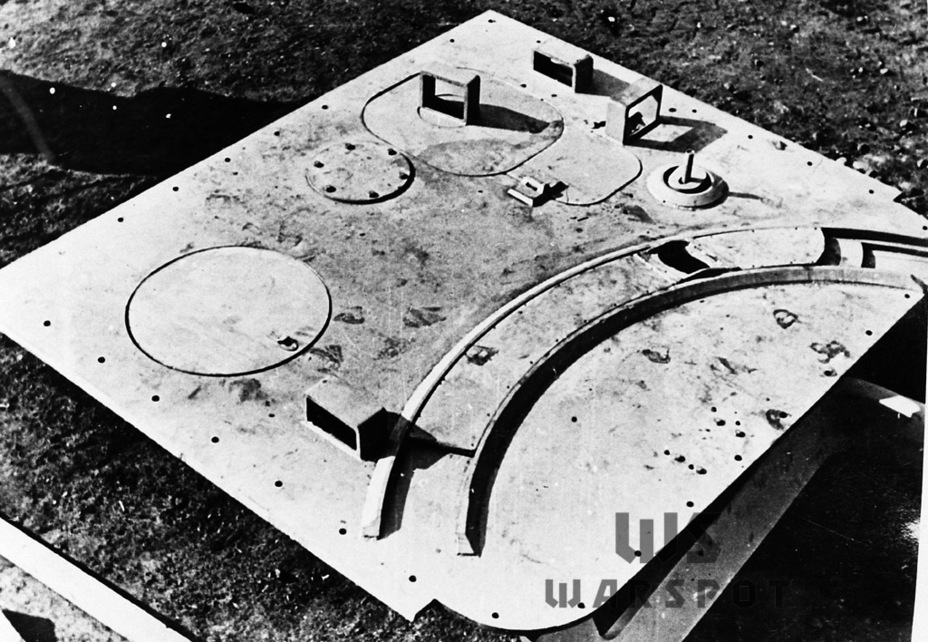

This design also had its drawbacks. Instead of a commander's cupola, the commander just had a rotating periscope in his hatch with two more periscopes looking forward and to the left. However, a cupola could have also added an extra weakness.

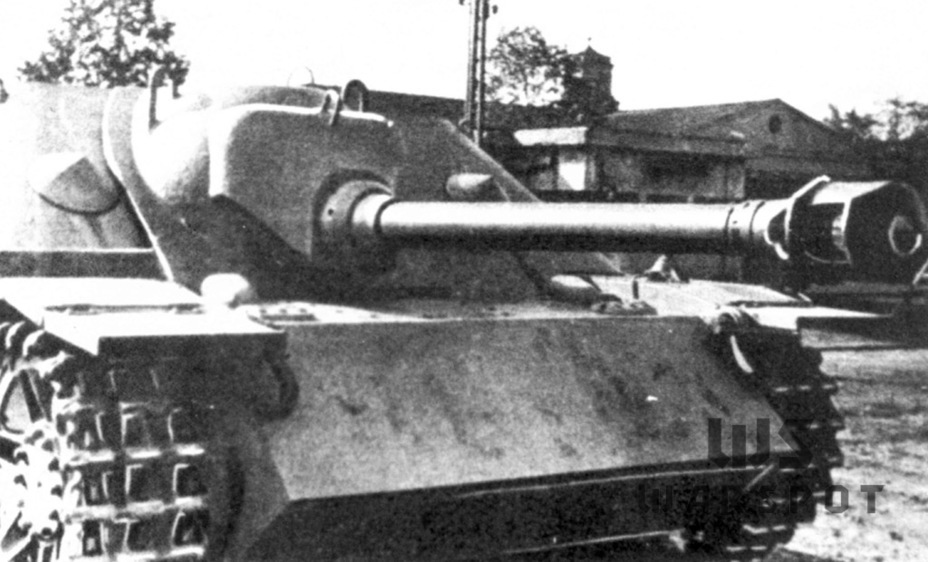

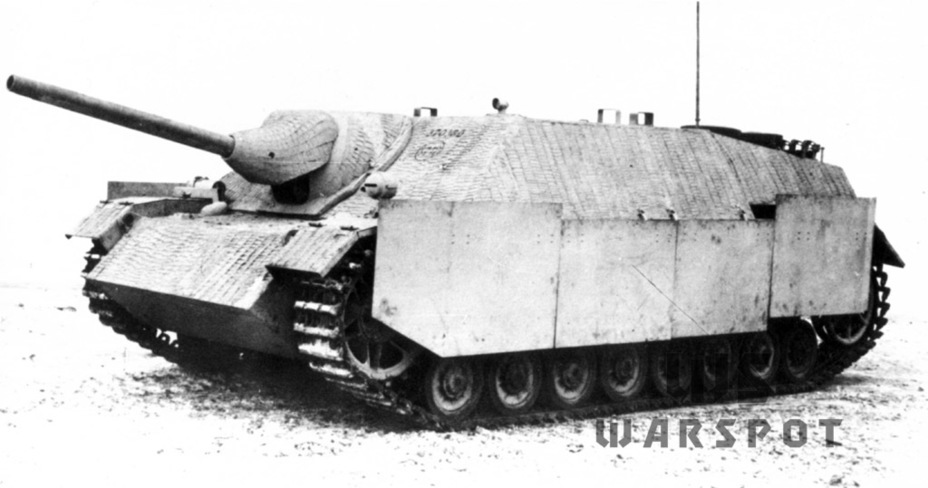

Requirements for the SPG were approved in February of 1943. A model built on the chassis of a Pz.Kpfw.IV Ausf.F was ready in the spring. The wooden casemate had interesting features: rounded joints of the front and sides. Some changes were implemented after the model was built. The driver's observation device was changed. Defensive armament was added: two MG 42s in the front plate covered by conical shutters. They were only useful for scaring off enemy infantry, but this was better than nothing. This was the form in which the kleine Panzerjäger der Firma VOMAG was shown to Hitler.

The project continued to evolve. The front of the hull was changed. Even the thickened front of the Pz.Kpfw.IV Ausf.G turned out to be vulnerable to guns bigger than 76 mm. As the mass of the vehicle already threatened to cross reasonable limits, the solution was slightly unexpected. Instead of one 80 mm plate at 78 degrees, two were used: the upper was 60 mm thick at 45 degrees, the lower was 50 mm thick at 35 degrees. The horizontal part with transmission access hatches remained. The medium SPG maintained protection comparable to that of a heavy tank at a mass of only 24 tons.

The first experimental prototype was named Panzerjäger aus Fg.St. Panzer IV (tank destroyer on the Pz.Kpfw.IV chassis). It received a new gun mantlet, an even larger one. As an aside, the name of the SPG changed at least three times in 1943 alone. The new vehicle also received side skirts. Unlike the skirts used on the Pz.Kpfw.III, Pz.Kpfw.IV, and StuG 40, these only covered the running gear. They were an addition to the spaced armour initially used to cover the engine compartment.

Hitler inspected the prototype on October 20th, 1943. Permission was given to put it into production.

Tank destroyer with room to spare

The acceptance of the Panzerjäger aus Fg.St. Panzer IV into service was timely. British and American bombers began to make their own corrections to German manufacturing programs in the spring of 1943. The Alkett factory was bombed on November 26th and 28th. The work in Spandau froze and a reserve production base for SPGs was urgently needed. This is where an SPG with a superior design to the StuG 40 came in very handy.

Factories which built the Pz.Kpfw.IV tank, including Grusonwerk, were pressed into building SPGs after Alkett was bombed. One could expect that Grusonwerk would start building VOMAG's design, but instead they quickly developed the StuG IV, a hybrid of the StuG 40 casemate and Pz.Kpfw.IV chassis. A «centaur» with the Pz.Kpfw.IV chassis and a Panzer IV/70(V) chassis called Panzer IV/70(A) was also developed at Alkett. Production of the Panzer IV/70(V) began in August of 1944.

The situation was bordering on the absurd. Between August and November of 1944 the Germans were producing five different SPGs on three different chassis in the same weight class with 75 mm guns. This is not including the Jagdpanzer 38, a budget alternative to the StuG 40.

VOMAG was the only factory that managed to design a good vehicle, however it was not immune from the «wonders» of German tank industry. The Armament Directorate couldn't think of anything better than to order the armour from VHHT (Vítkovické horní a hutní těžířstvo, modern day Vítkovice Steel) in Ostrava, Czechia. This was clearly a poor move. The brittle nature of Czech armour was known even before WWII, and the arrival of the Germans did nothing to fix this. The protection of the German SPG dropped before it even went into production.

The difference in quality was seen when hit by 85 mm shells and larger. Pretty graphs shown in many books should be treated with scepticism, as the penetration displayed is almost always theoretical. In practice, the armour of German SPGs often behaved very differently.

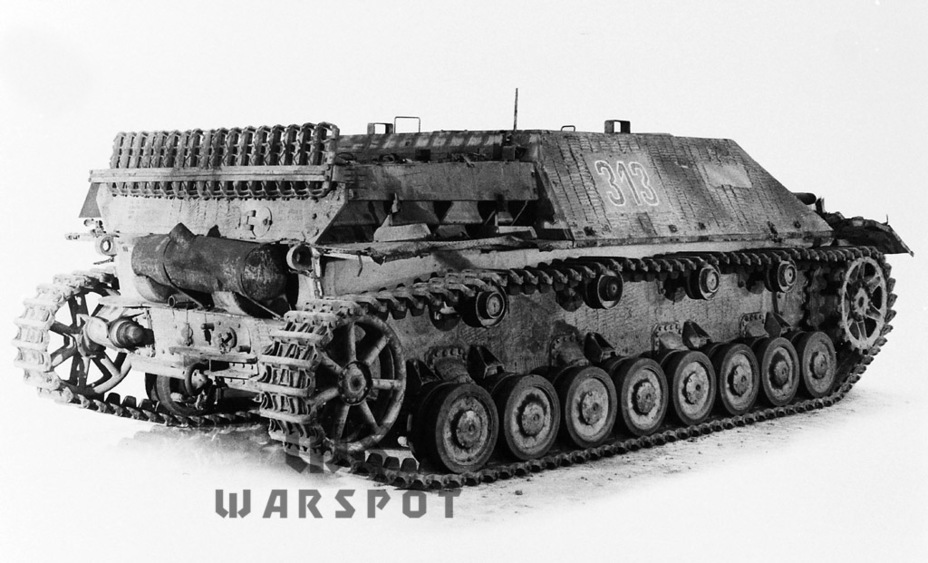

Delays with hull production were the limiting factor. Plans made in June of 1943 called for the delivery of 10 vehicles in September of 1943, 20 in October, 30 in November, and 40 in December. In practice, the second prototype was only finished in November. The hull changed little, but the gun mantlet was noticeably different. The vehicle received a coat of Zimmerit.

The mess with indices led to the vehicle being named Panzerjäger 39 mit Pak 39 kal. 7,5 cm L/48. This name later transformed into a rumour of an E-39 tank destroyer, which never existed. There was also a version of the SPG with 6 road wheels per side based on the Pz.Kpfw.III/IV chassis. It was redone several times but never built in metal.

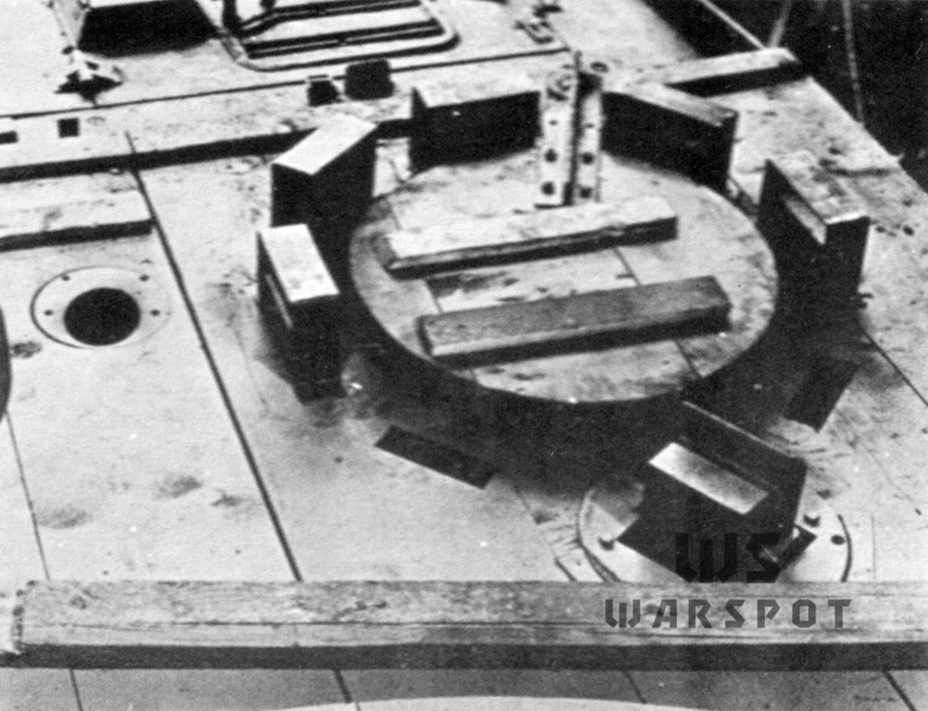

The production vehicle received the name le.Pz.Jg.IV in January of 1944. Work on production SPGs began in December, but they were slightly different. The rounded joints had to go, and there were issues with cast components. Although VOMAG received 46 hulls and 25 turret platforms by the end of 1943, only 10 le.Pz.Jg.IV were built and none were delivered to the customer.

Issues with hulls continued to slow down production. The plan was to build 50 vehicles in January, 60 in February, 90 in March, 120 in April, and 140 in May. In practice, only 30 were finished in January of 1944, 10 of which were the ones built in December. 45 were delivered in February, 75 in March and 106 in April. The supply issues were not just with hulls. There was supposed to be a bomb thrower in the roof, but no vehicles built in January had one, as they were not delivered. They did begin arriving later, but a part of the vehicles never had them.

The vehicle continued to change even after it was put into production. Initially, spare tracks were attached to the upper front plate, but they were moved to the back as of February 1944. Attachments for two spare road wheels were installed on the engine deck. The machine gun port on the left of the front plate was removed, as there were many issues with that mount, and the opening was welded shut on those hulls where it was cut.

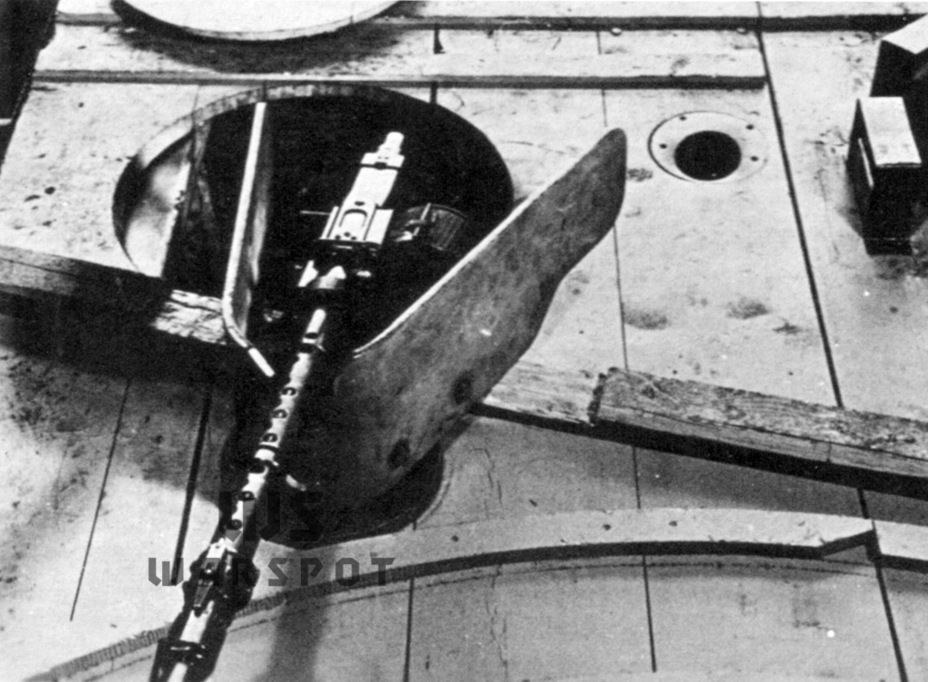

The right hand machine gun mount used by the loader was also pretty pointless, but it seemed like a bad idea to leave the SPG without any defensive armament at all. Experiments with alternative armaments began in the spring of 1944. In March-April a number of vehicles were equipped with remote control machine gun turrets, but these proved poor. The right machine gun port remained.

Another issue with the le.Pz.Jg.IV was poor visibility from the commander's station. His observation devices were insufficient for proper vision. SPG #320036 was used to test a semblance of a commander's cupola with a rotating periscope in one of the hatch flaps. Trials held in April of 1944 showed that the results were mixed. The commander's vision improved, but there was still an impressive dead zone. A decision was made to keep the hatch as is.

The third issue was easily solved. Firing the gun raised a large cloud of dust due to the gases coming out of the muzzle brake. The muzzle brake was removed from the le.Pz.Jg.IV in April-May of 1944. A reinforced recoil brake cylinder was added to compensate.

90 vehicles named Panzerjager IV (Sd.Kfz.162) were built in May of 1944. By the spring of 1944 it was clear that 60 mm of front armour was not enough. The thickness was increased to 80 mm starting with vehicle #320301. The diameter of the machine gun port cover was increased at the same time. The mass of the SPG increased slightly.

Production of the Panzerjager IV reached planned levels only in the summer of 1944. Cessation of production of the Pz.Kpfw.IV at VOMAG helped. As planned, 120 Panzerjager IV were completed in June. In July, 125 were built out of 130. This was the peak of production.

The idea to install an L/70 gun into the SPG remained, and the result was the Panzer IV lang (V). Production began in August of 1944, but production of the Panzerjager IV continued since there was a backlog of parts. 92 vehicles with L/48 guns were finished with a plan for 80.

The Panzer IV/70 (V) and the older vehicle that changed its name to Jadgpanzer IV Ausf.F in September were produced in parallel. The last changes to the Jagdpanzer IV were introduced in September. Straight exhaust pipes with flash suppressors replaced the muffler. They had a big drawback: water could enter the vertical pipes during rain. Because of this, special attachments were installed.

Additionally, the Germans finally figured out that the Red Army had no magnetic mines. Application of Zimmerit ended. 38 Jagdpanzer IV were built in September, 46 in October, and the last two were delivered in November. A total of 769 Jagdpanzer IV were built (not including the 2 prototypes). Production vehicles received serial numbers ranging from 320001-321000. This range also includes 231 Panzer IV/70.

Support for tank divisions

The StuG III and StuG 40 were sent to assault artillery battalions that were subordinate to infantry units. This was not the case with the Jagdpanzer IV. Even though its characteristics were very similar, the Germans had another task in mind. It was meant to replace the Marder II and Marder III tank destroyers, especially in tank divisions. These vehicles worked well as tank destroyers, but they were too small and had very thin armour.

The first 45 Jagdpanzer IV were issued in February of 1944. The first recipient was the Panzer Lehr division. The Jagdpanzer IV were supposed to be issued in anti-tank batteries within anti-tank battalions. According to TO&E KStN 1149 issued on February 1st, 1944, a battery could include 10 or 14 SPGs. 14 SPGs were sent to the 2nd Tank Division in April of 1944. 12th SS division Hitlerjugend received 10 in April of 1944, as did the 6th and 19th Tank Divisions in July of 1944.

The Panzer Lehr received 31 vehicles. Initially they expected to form a battery of 14 Jagdpanzer IV and 14 Jagdtiger, but heavy tank destroyer production stalled. The result was a new type of formation: a tank destroyer battalion. 4 vehicles were included in the HQ and 9 more spread out across three batteries.

The most common unit to use this vehicle was the battalion with 2 batteries of 10 each and a commander's vehicle (21 in total). The aforementioned 2nd Tank Division received such a battalion. In addition to the initial 14 SPGs they received another 7. The 12th SS, 6th, and 19th Tank Divisions eventually received 11 additional vehicles to form a 21-SPG battalion. Battalions containing 21 Jagdpanzer IV were also issued to Panzergrenadier divisions within both the Wehrmacht and the SS.

Even though the first Jagdpanzer IV arrived in March of 1944, they were not used in battle for some time. The vehicles were attached to units are they arrived either in France or in the deep rear on the Eastern Front to refit. The Luftwaffe field divisions, namely Hermann Goering, were the first to use these vehicles in battle. This happened on May 24th, 1944, in Italy. The division had 21 Jagdpanzer IV. By June 1st 5 vehicles were permanently lost and only 9 remained by July 1st.

Judging by diagrams that migrate from book to book, the front armour of the Jagdpanzer IV was immune to American 75 mm guns, and the 76 mm guns used on the M10 and M18 tank destroyers could only penetrate them from 100 meters.

The result of the fighting in Italy was somewhat different than the diagrams would suggest. A number of these vehicles were penetrated frontally, and it was unlikely to have been from point blank range. Theoretical calculations are often different from practice.

Similar penetrations can be seen in vehicles lost in Normandy. The aforementioned Panzer Lehr initially fought very well and lost only one vehicle. Fortune came up short in July, when total losses numbered 19. American GMCs and now even Sherman tanks penetrated the front of the Jagdpanzer IV with envious regularity.

This problem was solved only by thickening the front armour of the vehicle to 80 mm, but this helped only partially. The information that the D-25 gun in the IS-2 heavy tank could only penetrate the Jagdpanzer IV from 600 meters looks laughable, as the D-25 could penetrate the Panther (the same 80 mm at a similar angle) from a range of up to 2.5 km.

The thickening of the front armour did not rid the Jagdpanzer IV of all of its weaknesses, as the machine gun port and the driver's vision block remained. A hit to the vision block was often fatal for the SPG and its crew.

Despite its issues, the Jagdpanzer IV was one of the best medium SPGs on both sides of the front in the summer of 1944. Of course, the poor quality of armour reduced the effectiveness of the frontal protection, but context is key. The Jagdpanzer IV's peers, the GMC M10 and SU-85, had similar guns but thinner armour, especially from the sides. Another advantage of the Jagdpanzer IV was the low silhouette, an important factor for a tank destroyer. The mobility also remained at the level of the Pz.Kpfw.IV, which was sufficient.

If one treats the Jagdpanzer IV as a replacement for the Marder III, then VOMAG's designers did their jobs well. The problem was with the German leadership who decided to produce these vehicles at VOMAG alone. It was the Jagdpanzer IV and not the Jagdpanzer 38 that could have made the work of Soviet, American, and British tankers much more difficult in the concluding period of the war.

A second mistake was the replacement of the Jagdpanzer IV with the Panzer IV/70(V). This SPG deserves a separate article. Here, let's just say that the L/70 gun was not the best option. The new gun came with a whole bundle of issues, including overloading of the front wheels and a drastic drop in mobility. The «fishing rod» was also excessive when it came to fighting medium tanks.

The fact that this was a mistake is highlighted by post-war use of VOMAG's SPGs. The Panzer IV/70 was hardly used anywhere (a few vehicles were used by the Bulgarian army), but the Jagdpanzer IV's career was much more interesting. 15 of these SPGs were used by Bulgaria, one of them survived to this day as a pillbox. 6 vehicles sold by the French to Syria lived interesting lives and were last used in battle in 1967. The remains of one of Syria's Jagdpanzer IVs still gather rust on Golan Heights.

Translated by Peter Samsonov. Read more interesting tank articles on his blog Tank Archives.

Sources:

- Panzer Tracts 9-2 Jagdpanzer: Jagdpanzer IV, Panzer IV/70 (V), and Panzer IV/70 (A) development and production from 1945 to 1945, Thomas L. Jentz, Hilary Louis Doyle, 2012;

- Light Jagdpanzer: Development — Production – Operations, Walter J. Spielberger, Hilary L. Doyle, Thomas L. Jentz, Schiffer Pub Ltd, 2007, ISBN 978-0764326233;

- National Archives and Records Administration.