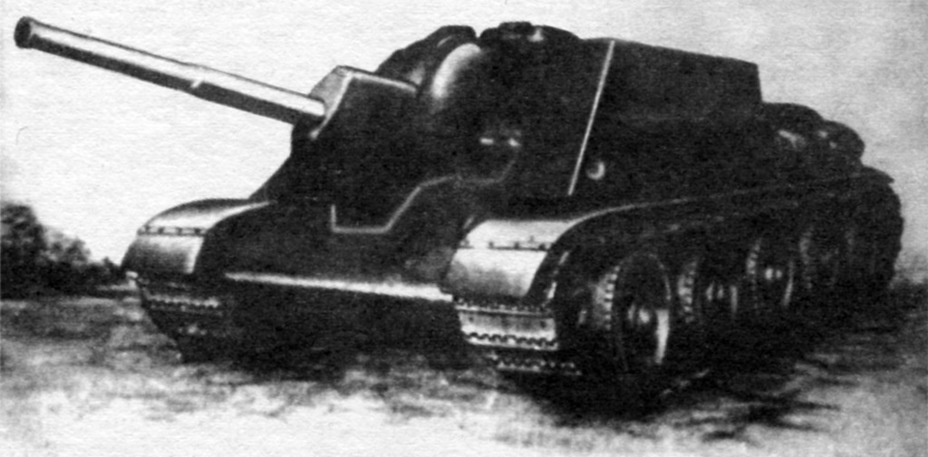

Development of armoured vehicles in many nations proceeds in parallel. A clear example of this is the creation of German and Soviet medium SPGs. Initially, Soviet SPGs were built as tank destroyers. Later, under the influence of the German StuG III Ausf. B, the medium assault gun program was launched, which gave birth to the SU-122. By this time, the Germans had modernized the StuG III and transformed it into primarily a tank destroyer. This SPG was known as the StuG 40. In the USSR this process took longer, as there was no gun to combat German heavy tanks until the spring of 1943. That is when the SU-85 appeared, the most numerous Soviet medium SPG used in the war.

Anti-Tiger measure

Work on an SPG armed with the 85 mm 52-K AA gun stopped in the spring of 1942. Designers moved on to assault SPGs. However, work on 85 mm tank guns continued, but not a single one made it past the point of a sketch.

Sometime in early 1943 (no precise date is available) the factory #9 design bureau headed by F.F. Petrov began working on a continuation to a family of towed guns on the 122 mm M-30 and 152 mm ML-20 gun carriages, which they started working on back in the fall of 1942 as a part of factory #8's design bureau. The following barrels were to be installed on the M-30 carriage:

- 107 mm model 1910/30 (ZIK-30)

- 107 mm M-60 (9S-1)

- 122 mm A-19 corps gun (D-2)

- 152 mm M-10 howitzer (D-1)

The 9S-1 and D-2 reached the trials stage, and the D-1 was even accepted into service with the Red Army and remained in use throughout the world for decades. A system similar to the D-2, the M-5, was created at the factory #172 design bureau. Neither gun was adopted into production, but the results of working on the D-2 were put to good use. The idea of installing the gun on the M-30 carriage was good. Later, this design was used to create the famous D-25T gun.

As for the development of 107 mm guns, it hit a dead end. However, an SPG with this gun was still designed.

No documents survive to this day, not even the name of this SPG is known. Some call it the U-34, but this index was never used. In practice, this was the same SU-122, whose design was finalized only in December of 1942. It is likely that this project is dated early 1943. Its development is linked to the attempt to combine many gun systems on one carriage. It is now known what gun was to be used: the ZIK-30 or 9S-1.

However, by this time the star of the 107 mm guns had set, and even the basic variant of the SU-122 was under question. The SPG was very cramped, and discussion of the SU-35M or SU-122M began. Instead of the M-30, this SPG used the D-11 howitzer, which was much harder to combine with a 107 mm barrel. It is not surprising that this grassroots project without a name disappeared quickly, leaving almost no trace.

The results of trials against a captured Tiger tank in late April of 1943 were like a bomb that fell on Soviet tank design. The 76 mm gun could not penetrate it in the side at even close range, and not a single one of 15 shots fired from the M-30 howitzer resulted in a fair penetration. However, the 85 mm 52-K AA gun proved itself very effective. It successfully penetrated the front of a Tiger from 1000 meters.

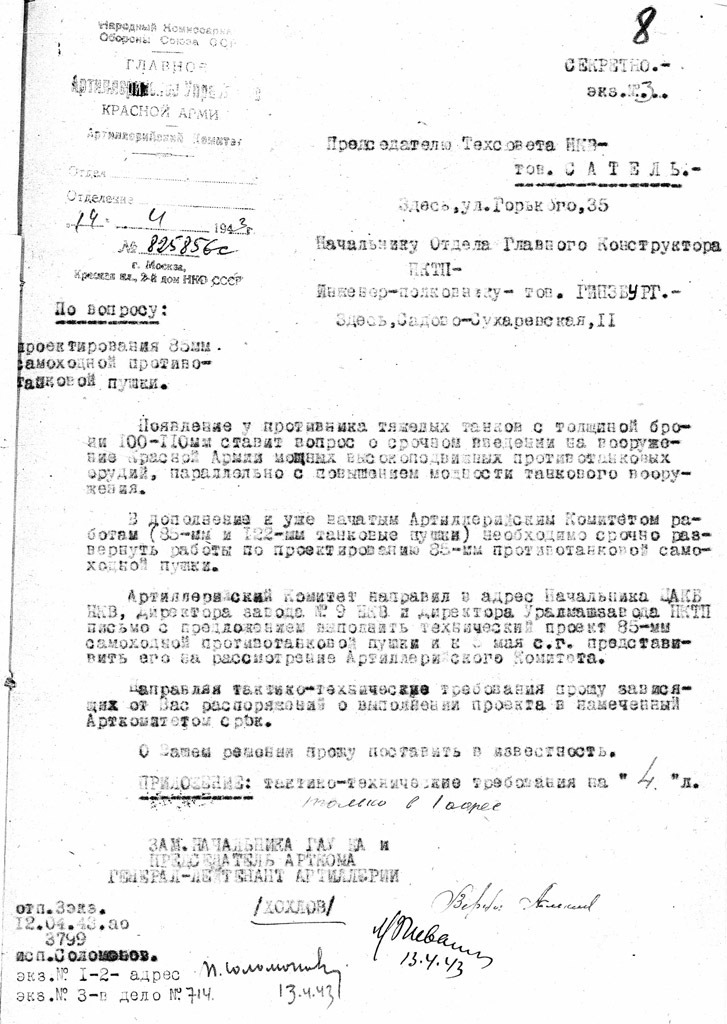

Work on installing this gun on the chassis of the SU-122 began immediately after obtaining the results of the trials. To be precise, work that was already ongoing was retroactively approved. The Red Army Main Artillery Directorate (GAU) developed technical requirements for an 85 mm self propelled gun/tank destroyer on April 12th. This development was directly linked with the appearance of the Tiger. The main enemy of this tank destroyer would be enemy heavy tanks with 90-120 mm of armour, which the 85 mm gun confidently penetrated at a range of 500-1000 meters. According to requirements, the gun would be installed in the chassis of a SU-35M (SU-122M) SPG, which would have to be lightened by 1-1.5 tons. The gun would carry 60 rounds of ammunition, either vertical or horizontal ammunition racks were permitted. Interestingly enough, captured German PzIII and PzIV tanks were suggested as an alternative chassis.

The requirements were approved by the GAU Artillery Committee on April 14th. On the same day, they were sent to the Kaliningrad, where the Central Artillery Design Bureau (TsAKB) was located. The letter from the chair of the Artillery Committee, Lieutenant General V.I. Hohlov, instructed the head of the design bureau, V.G. Grabin, that the 85 mm gun was the highest priority. It would be created by combining a barrel with the ballistics of the 85 mm 52-K gun and the recoil elements of the ZIS-5 gun. This layout was no accident, as it was based on the earlier development of the ZIS-25 gun. The gun itself was rejected based on a number of drawbacks, but the overall idea was deemed correct.

The GAU composed requirements for an 85 mm tank gun that would be the successor to the ZIS-25 on March 6th, 1943. This was the starting point for the design of the new SPG. In addition to the TsAKB, the requirements for an 85 mm SPG were sent to Sverdlovsk to factory #9 director L.R. Gonor, and director of the Ural Heavy Machinebuilding Factory (UZTM) B.G. Murzukov. Factory #9's design bureau would develop the gun, the UZTM would develop the chassis.

The deadline was set at May 5th. By April 29th the TsAKB was already completing the preliminary project, but factory #9 had not even officially accepted the order. Nevertheless, a telephone call transcript indicates that work already began. By the time GKO decree #3289 «On improvement of artillery armament of tanks and SPGs» was signed on May 5th, 1943, Soviet designers already had a certain backlog of work.

Three competitors on one chassis

Decree #3289 was an odd one. It didn't mention the TsAKB at all, and only the People's Commissariat of Tank Production, factory #9, and the Uralmash factory were identified as responsible for 85 mm guns. The decree ordered the production and delivery of two SPGs called SU-85 by July 1st, 1943. The start of the trials was postponed to July 10th. Factory #9 and Uralmash were instructed to prepare for production before trials ended.

Representative of the Artillery Committee Engineer-Major P.F. Solomonov arrived at factory #9 on May 3rd. The director of the factory declined to develop the gun on that day, as the factory was busy with the D-11 and D-12. Things changed only on May 5th after Stalin signed decree #3289. On that day a meeting was called at factory #9 where a direction was decided upon. The D-11 gun was taken as the starting point. Guns for SPGs had a higher priority: the 85 mm gun received the index D-5 and the 122 mm gun was called D-6. The tank variants of these guns were called D-7 and D-8 respectively. Interestingly enough, the design bureau of factory #8 was working on an 85 mm tank gun as well. This strange because when factory #9 split off from factory #8 the latter no longer had a responsibility to design tank guns.

Judging by Solomonov's report, the reality was different. Little data about factory #8's project survives, but it is known that it used the cradle from the F-34 gun, and the changes to the barrel would allow the armour piercing shell to achieve a velocity of 930-960 m/s. By May 8th work was well underway and working blueprints were even prepared. However, an order arrived from the NKV on May 10th to stop this work. The NKV reminded the factory that its job was to focus on towed guns.

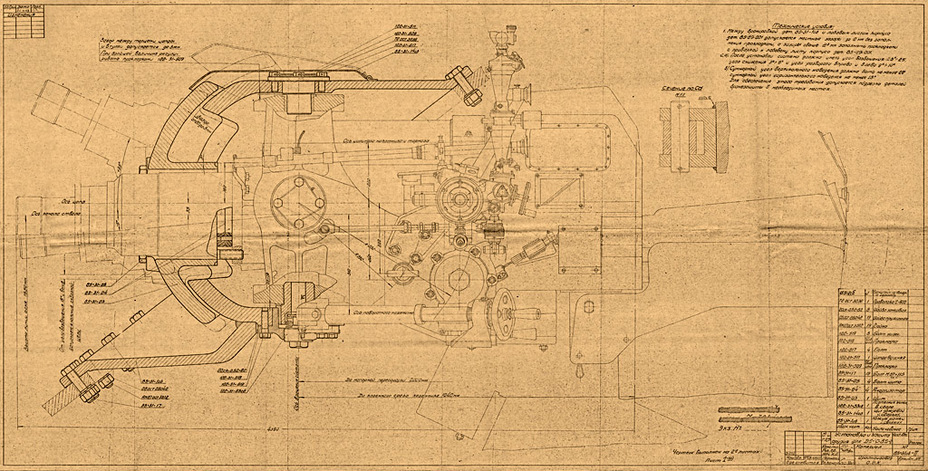

Factory #9 gave new names to its guns: the D-5 became the D5-S-85, and the D-6 became the D5-S-122. The idea of using the ZIS-5 cradle vanished, and F.F. Petrov's bureau ignored some other requirements as well. The new gun was a further development of the U-11 gun, work on which began in the fall of 1941.

Recall that the U-11 was designed as a duplex. In addition to the barrel of the M-30 howitzer the U-12 with the ballistics of the 52-K 85 mm AA gun was later developed. The new gun was a reincarnation of this project, especially since the task of replacing the M-30 in the SU-122 still had to be done. In May of 1943 work on a very similar system with a 122 mm barrel began, the D-2. This work ended with the D-25, the most powerful Soviet tank gun mass produced during the Great Patriotic War. Also the D-15 gun with the barrel of the D-1 152 mm howitzer was designed in the fall of 1943. Unlike the D-25, it was never built. Nevertheless, its design alone demonstrates the versatility of the design.

The D5-S-85 was a further development of the 122 mm D-11 gun. As with that gun, the development was directed by deputy chief designer A.N. Bulashev and deputy design bureau chief N.V. Kastryulin. During the development of the SPG duplex the designers took into account their past mistakes. The new gun was more compact and the mantlet was not as massive. A large casing in the front of the gun was done away with due to a redesign.

The elevation mechanism was borrowed from the F-34 for the sake of unification. All four guns had a common recoil brake, recuperator, and cradle. The D5-S-85 and D5-S-122 also had the same sight, frame, turning mechanism, and sight illumination. The D-5S-85 and D-5T-85 had the same recoil guard and brass catcher. Since the casing of the 52-K was longer, the guard had to be longer than that of the D-5S-122. Calculations showed that the recoil length of 350-370 mm was impossible, so it had to be increased to 430 mm

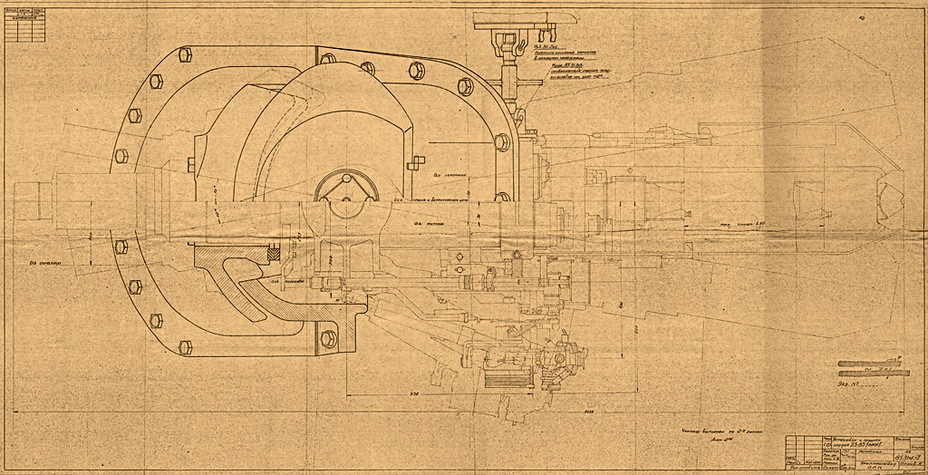

Design documentation for the D-5 family was ready by May 26th, 1943. At the same time, the competition from the TsAKB was working much faster. An SPG design with the S-18 gun was ready by May 16th, 1943. It turned out that 60 rounds would not fit, and only 50 would be carried. Unlike the factory #8 design, this gun was not a duplex. The project, headed by the head of the 3rd department of the TsAKB E.V. Sinilshikov, was developed only for installation into an SPG and only took an 85 mm barrel. Like with the D-5, the TsAKB did not use a pedestal mount, instead using a frame. The bore axis height increased from 1400 to 1600 mm, but the mass dropped from 30 to 29.5 tons. As required, the TsAKB maintained parts commonality with the ZIS-5 gun. Over 70% of the parts were reused. One of the biggest issues of the S-18 was the recoil length. At 470-570 mm it was nearly 1.5 times longer than required.

First place loser

The opposition of factory #9 and TsAKB followed a course that would later be repeated with tank guns. Grabin's group had time on their side, but the designers from Sverdlovsk had the advantage of a more developed system and physical closeness to the SPG factories.

The glacial pace of D-5 development led to the TsAKB taking an early lead by the end of May 1943 both in tank and SPG guns: first the S-31 gun for tanks, then the S-18 for SPGs. Factory #9 received blueprints of the S-31 by May 20th. Nearly all documentation for the S-18 was also delivered by then, aside from the traverse mechanism, sight adapter, and toolkit. Final documentation arrived on May 31st, in time for the deadline set by NKV and NKTP order #283ss/260ss given on May 8th, 1943.

A number of issues were identified with the TsAKB's SPG during development. The commission remarked on a lack of communication between the TsAKB and UZTM, which resulted in some shortcomings of the design. According to conclusions made on June 8th, 1943, the SU-85 with the S-18 gun had decreased visibility from the driver's and commander's positions. Removal of the breech operator, which the TsAKB thought unnecessary in a vehicle with one piece amunition, was also criticised. Finally, moving the center of mass forward by 14 cm added stress to the front road wheels. The UZTM design bureau suggested that the TsAKB should change its gun by altering the ammunition racks and moving the gun back. At the same time, the oscillating part of the system would have to be narrowed. This variant was approved, but the TsAKB insisted on the initial design.

A trials program was approved on June 24th, 1942. The document listed three guns: S-18, D-5S-85, and the S-18 with changes requested by the UZTM. However, in June and even early July the chassis were not available. The S-18 was only tested in a jig on June 18th. Gun #5 made 23 shots, of which 1 had a reduced charge, 11 had a regular charge, and 11 were supercharged. Firing was done at various angles. The trials completed successfully, extraction happened without issues.

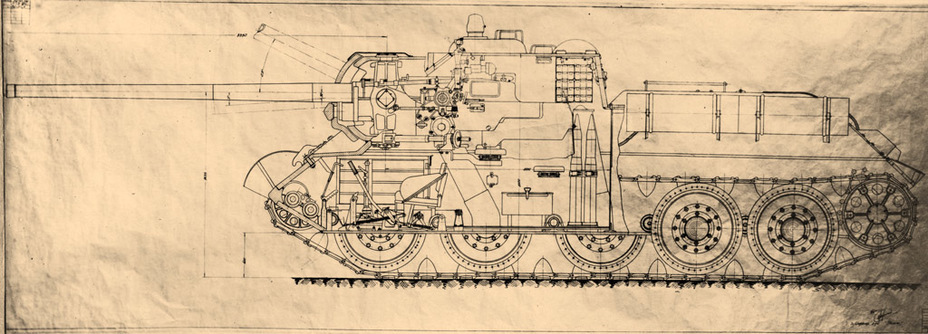

The initial TsAKB variant received the name SU-85-IV. It was still subject to some changes: the gun mount changed slightly, and a cap was introduced to protect the frame from water and dirt. The gun itself was also improved. The driver's working conditions became more comfortable. The changes in the fighting compartment were more radical. The TsAKB's idea to make a large ammo rack in the rear right corner was rejected, as it would have been uncomfortable to use. Ammunition was placed around the sides of the fighting compartment, under the gun, and in the left sponson. The ammunition capacity was reduced to 48 rounds, but it was now much easier to use it. The number of crewmen increased to 5, and the commander received a cupola in the roof. The cupola contained periscopic observation devices. The vehicle was accepted for trials in this configuration.

The biggest issue with the S-31 at this time was a lack of potential for improvement. The GAU wanted to increase the muzzle velocity of the gun. On May 4th the Artillery Committee began a project on 85 mm guns with a barrel length increased by 12 calibers and muzzle velocity increased to 950 m/s. The S-31 was incapable of such results. This was the cost of parts commonality. The same was true for the S-18.

The UZTM began working on converting the S-18 in early July of 1943. Experience of the D-5 family was considered when working on this gun, indexed S-18-1. As a result, it ended up having some parts in common with the D-5S-85, including elements of the frame and mantlet. The biggest change was the gun shield. The shape changed and a small hatch for access to the hydraulic system was added in the center. The height of the bore axis increased to 1635 mm.

The fighting compartment of the SU-85-I was identical to that of the SU-85-II. Nevertheless, the more rational design of the SU-18-1 had an effect. The mass dropped from 30 to 29.66 tons. Thanks to the more compact gun mount the overall length of the SPG shrank from 8320 to 8310 mm. The thickness of the gun mantlet grew from 30-45 to 52 mm, but its mass was reduced from 860 to 500 kg. The S-18-1 weighed 1160 kg without a shield. To compare, the S-18 weighed 1310 kg and the D-5S-85 weighed 1215 kg.

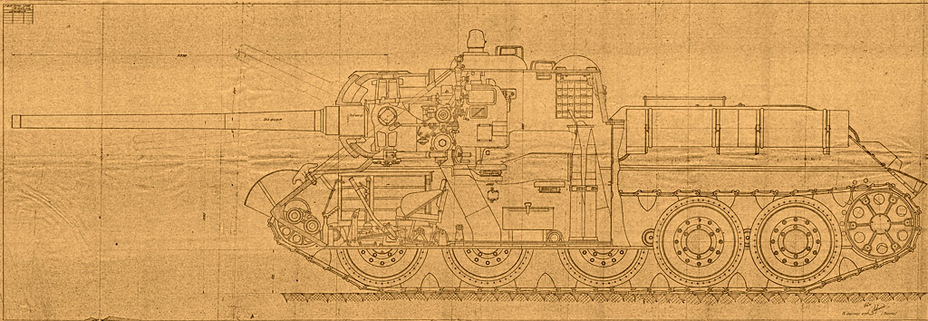

The commission found no serious drawbacks with the D-5S-85. The smaller size and mass allowed the gun to better fit into the SU-85. The SU-85 with factory #9's gun received the name SU-85-II. It was very similar to the SU-85-I and SU-85-IV. The crew consisted of 5 men. The mass was 29.15 tons, the lightest of all.

The deadlines set by GKO decree #3289 were not met. The development of the SU-85 went well into July. Experimental prototypes were completed by July 20th, and the vehicles arrived at the Gorohovets proving grounds on July 25th. Trials began that same day. First, the SPGs were inspected and loaded to full combat weight. Each one travelled 485 km from July 29th to August 1st, 373 km on a highway and 112 off-road. The SPGs drove from Sverdlovsk to Chelyabinsk and back.

The average speed on the highway was 22-24 kph, and 16-18 kph off-road. This was almost the same as a standard T-34. After long marches at a speed of over 25 kph the road wheels would take damage. This was a problem not only with the SU-85, but with the T-34. The mobility of the SU-85 was about the same as of the T-34. The new driver's hatch was nearly identical to that of the T-34 and provided good visibility. The exception was the SU-85-IV, where the massive gun shield covered up vision to the right. A common drawback of all SU-85s and the SU-122-III was the shifting of the driver's seat to the right of the hatch center, which reduced visibility somewhat.

The guns were inspected after the trials. It turned out that the vertical looseness of all of them increased, especially of the S-18-1.

Firing trials were conducted on August 3-4th. The D-5S-85 almost immediately took the lead, chiefly due to superior crew comfort. Thanks to its smaller recoil length and loading height, the rate of fire was the highest. The S-18 and S-18-1 achieved a rate of fire of 6-7 RPM, the D-5S-85 could fire at 8 RPM. However, none of the guns passed trials. The D-5S-85 was in the lead, but it had issues with the trigger mechanism and 30% of extractions did not happen cleanly. The recoil brake began leaking after 10 shots. After 266 shots the brake lost about a liter of hydraulic fluid. The gun short-stroked on the 267th shot and the recoil brake broke. The gun had design flaws as well: the trigger mechanism was in an uncomfortable place and was hard to operate.

However, the issues with the D-5S-85 were nothing compared to what the TsAKB gun produced. Problems began with the 5th shot and continued throughout the trials. Over 80 shots the semiautomatic mechanism failed 15 times. The breech would often close itself. The pressure in the recuperator reduced from 28 to 23 atmospheres after 40 shots. The fluid hydraulic also heated up quickly. There were many short strokes, and harsh returns with knocking began after the 70th shot. After 200 shots the mechanism broke completely. This gun had serious design defects, for instance the mantlet had to be removed to refill the hydraulic fluid.

The S-18-1 fared somewhat better, but many issues of the S-18-1 were also present. The recoil length gradually increased, after 173 shots the hydraulic fluid began to leak. Harsh with knocking began after 31 shots. Of the last 110 shots fired, 47 had the breech close itself.

After comparative trials work on the S-18 and S-18-1 ceased. The D-5S-85 was a clear winner. However, the final verdict was conditional on the resolution of defects with the gun. The chassis was also not fully satisfactory. A wider fighting compartment like on the SU-122M was proposed, but in practice the fighting compartment was not radically altered. The SU-85-II was accepted into service nearly unchanged. It happened on August 8th, 1943, when Stalin signed GKO decree #3892ss «On organization of 85 mm SPGs on the T-34 chassis at the Uralmash factory». The first production SPGs were built in August of 1943.

The SU-85 was the first mass produced Soviet SPG that was designed entirely in Sverdlovsk. UZTM staff received awards from the government for this project, the highest of which was the Stalin Prize. Factory #9 staff received high awards as well.

Translated by Peter Samsonov. Read more interesting tank articles on his blog Tank Archives.

Sources:

- Central Archives of the Russian Ministry of Defence;

- Russian State Archive of Socio-Political History;

- Russian State Archive of Economics.