Many tanks received significant upgrades after they first saw battle. Practice often trumps theory, especially during WWII where military vehicles quickly became obsolete. The IS-2 heavy tank was no exception. It was built with enough armour to protect it from the German Tiger tank, but it turned out that there were more dangerous opponents on the battlefield. As a result, a modernized IS-2 tank entered production in Chelyabinsk in late summer of 1944. It is sometimes call IS-2M or IS-2 model 1944, but neither designation was used in reality.

Away with the step!

The idea of improving the IS-2's armour was first considered in February-March 1944. The result was a not very successful debut of the tank's predecessor, the IS-85. The first battle at Lisyanka showed that the front armour can be penetrated by the 75 mm KwK 42 L/70 gun used on German Panther tanks. Manufacturing defects were partially to blame for insufficient protection, but it was clear that the front of the new tank was too weak against the Panther's gun. The IS-2 had the same hull and turret armour.

Work was aimed in two directions. GKO decree #5583ss «On production of experimental prototypes of new heavy tanks at the Kirov factory» was published on April 8th, 1944. The third item mandated necessary actions to reinforce the armour of the IS-2 to be taken within three months. It was also necessary to improve the transmission and running gear using elements developed for the Object 701 heavy tank. The IS-2 would go through a deep modernization. This work was done by both the SKB-2 of the Chelyabinsk Kirov factory and experimental factory #100. The experimental factory gave this work the highest priority. This resulted in the creation of several projects, however none of them made it out of the draft stage.

ChKZ's SKB-2 chose a different direction. Unlike the experimental factory, which had little ties to manufacturing, this design bureau understood the manufacturing process. Work on the Object 701 tank, the IS-2's replacement, was already underway. A radical modernization of the IS-2 could become a competitor for their own project. The requirement to increase production of the IS-2 and SPGs on its chassis also hung above ChKZ like the sword of Damocles. No work was performed to modernize the tank until at least mid-summer of 1944. However, the quality and design of the mass production tank was constantly improved. For instance, in June of 1944 a new turret and gun mantlet were introduced that improved protection from the front.

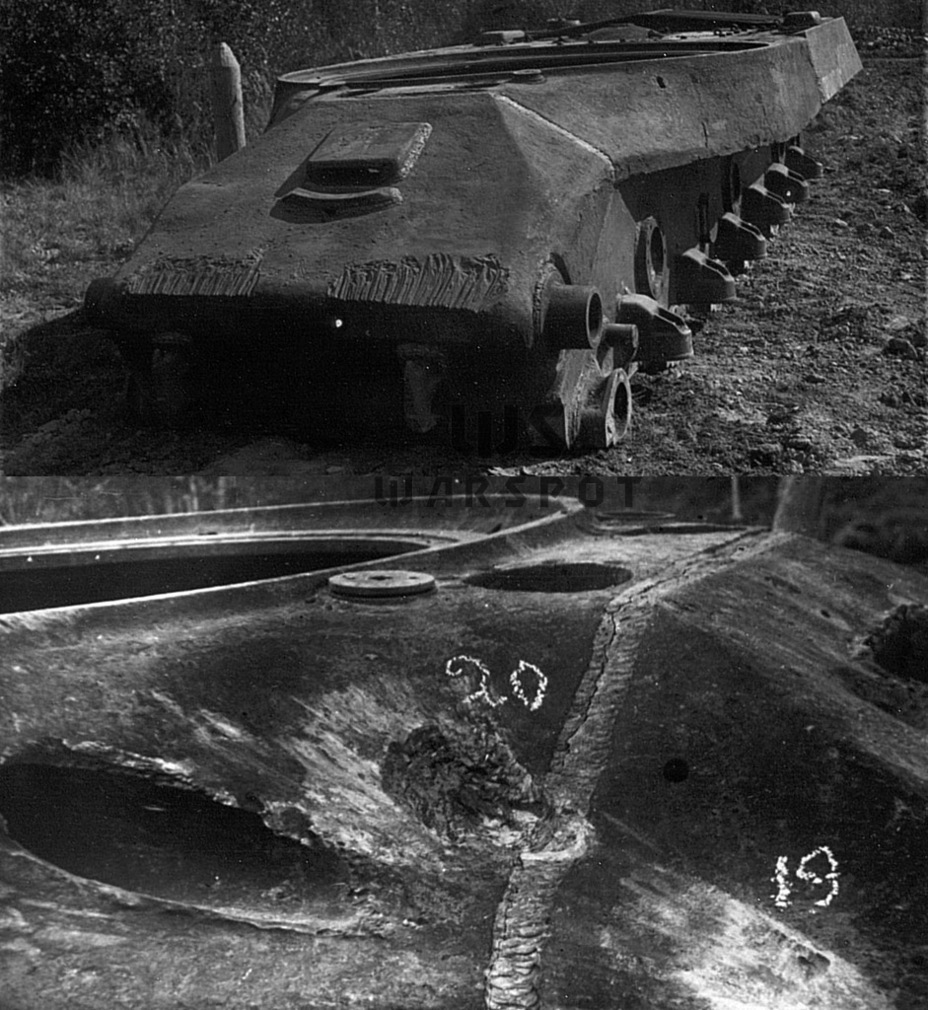

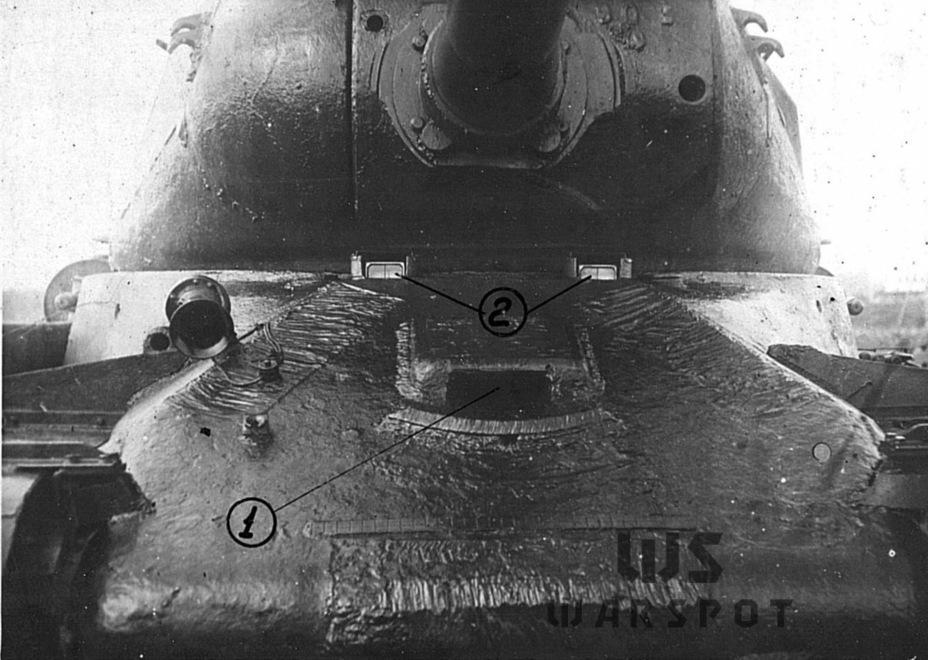

The most difficult part to improve was the front of the hull. Its characteristic «step» was inherited not even from the KV-13, but the KV-1. This was caused by a curve in the armour to accommodate the driver's observation device. This solution improved visibility but created a number of problems. This «step» made the front plate more complicated to produce, which often caused manufacturing defects. The observation port was also a weakness of the design. At Lisyanka a number of penetrations of the front hull were made through here. The upper part of the «step» had a reduced angle, which also did nothing to improve protection.

The designers declared war on the «step». The Object 701 was the first Soviet heavy tank to get rid of it. It was reasonable to migrate the solution from one tank to another.

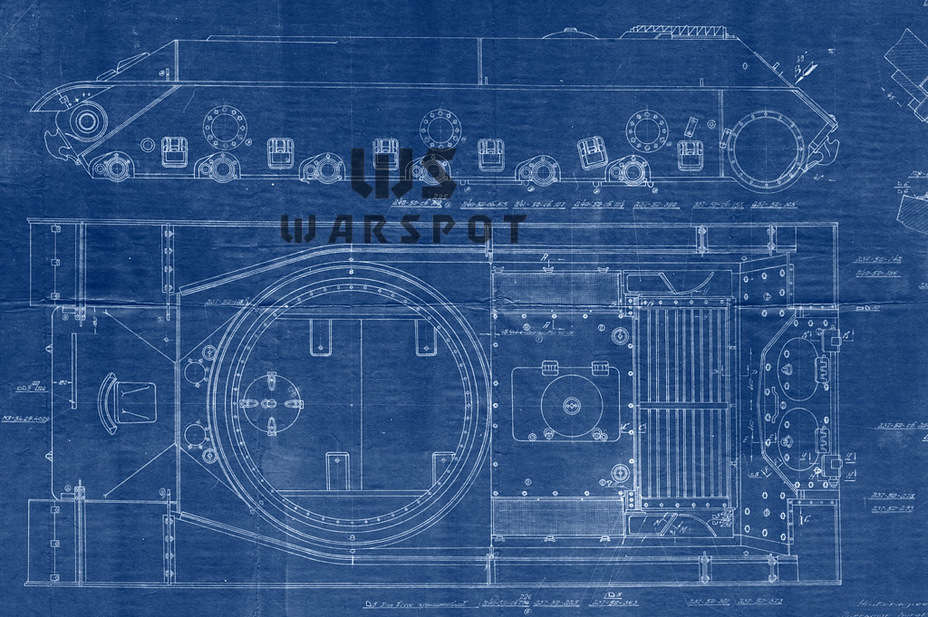

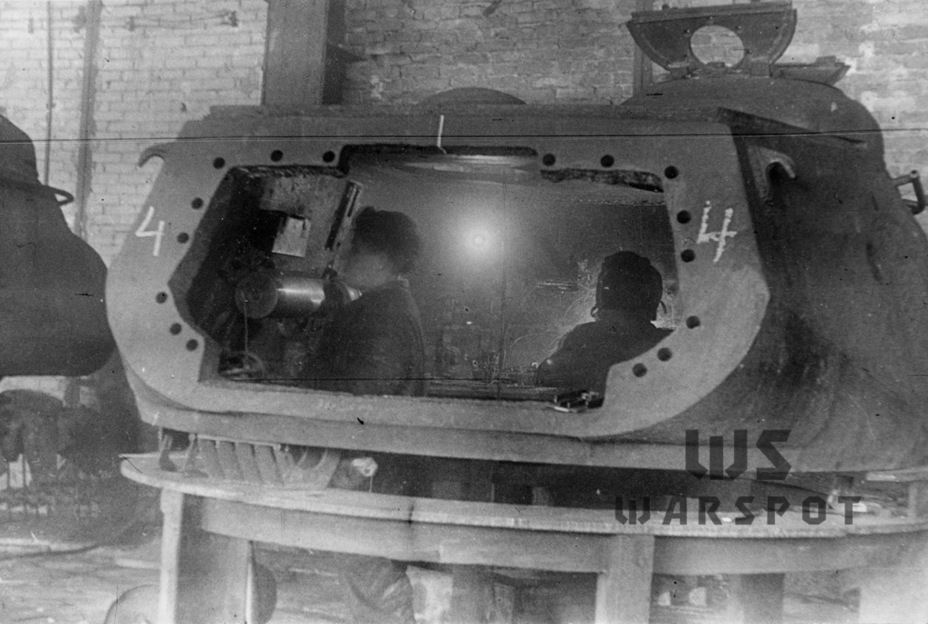

On April 14th, 1944, just one week after the GKO decree, SKB-2 prepared a blueprint of a modernized hull. According to requirements, the production of a single piece 90 mm welded front plate had the highest priority. Calculations showed that this design would be equivalent to much thicker cast armour. The front was assembled from two parts: the upper (240-50-77) and lower (240-50-131). The weld seam between the two was reinforced by interlocking. Instead of an observation port, the tank received an Object 701 style observation device (240-50-78) which was welded into the center of the upper plate. An arc shaped deflector protected it from shells that bounced off the upper front plate.

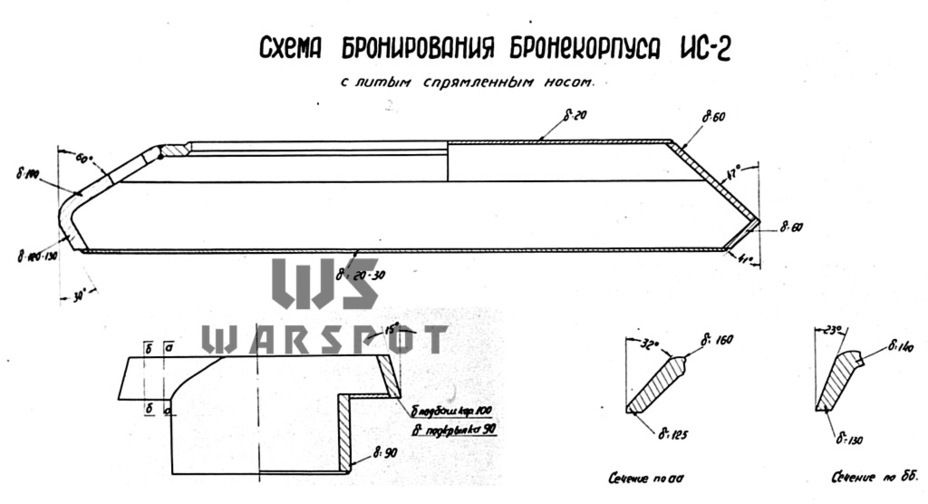

The upper plate, 240-50-77, was produced by stamping. The Ural Heavy Machinebuilding Factory (UZTM) had an appropriate press, which was used, in part, to built T-34 turrets. Alas, factory #200 had no such press. For this reason, by April 29th a different modernized hull variant was prepared. The front was now cast in one piece (part 240-50-141). The observation device and deflector were welded into it. Since the effectiveness of cast armour was lower than welded, its thickness was increased to 100 mm in the top section and 130 mm in the bottom. Changes to this part triggered changes of other parts of the hull, for instance the turret platform (part 240-50-Sb.127). The new part (240-50-Sb.166) had a narrower joint with the cast front section.

On May 10th, 1944, UZTM and factory #200 received letters from the People's Commissar of Tank Production Malyshev on delivery of hulls with straightened fronts to the NIBT proving grounds. However, no work was done on this in May. Production began in July and trials were carried out in September of 1944. By this time production of the modernized IS-2 had been underway at ChKZ for two months and the first tanks with the new hull already arrived at the front.

Firing trials showed that the welded front plate is impervious to 75 mm AP and APCR ammunition at all ranges. The lower front plate could be penetrated from 1.5 kilometers. The situation with the 88 mm Pak 43 installed on the Ferdinand tank destroyer was more dire. The upper armour could be penetrated from 450 meters, the lower from nearly 4 kilometers. The design of the weld seams was also criticized, as they cracked when hit.

The cast hull front produced by factory #200 was a different story. The factory was instructed to move to a cast design, but never did this. The factory didn't want to make the change, and more importantly could not do it. Trials showed that it was not necessary anyway. The upper front hull was not penetrated by the Pak 43 in most cases even at point blank range (in most favourable conditions it could penetrate from 255 meters). The lower part of the front hull was penetrated by the Panther's gun, but at a much lower range: 785 meters. The weld seams performed better, but there were still some complaints. The observation device was more vulnerable, but it turned out to be smaller than the old observation port and performed well.

The IS-2 became what the Panther was for Soviet medium tanks: only penetrable in the lower front plate or the turret from the front.

A significant drawback of the new front hull was the reduction of visibility for the driver. with a closed observation port the old IS-2's driver could see in a range of 9 degrees vertically and 40 degrees horizontally. With the port open his vision range increased to 27 degrees vertically and 75 horizontally. The new observation device provided 13 degrees of vision vertically and 30 degrees horizontally. The dead zone in front of the tank was 12 meters long. This drawback was compensated with two MK-IV observation devices, but they had a dead zone of 10 meters. The driver's vision definitely decreased. However, the dead zone on UZTM production hulls was less than that on factory #200 production hulls.

The Object 701 had a similar drawback. It is no surprise that as of late 1944 this type of observation device was done away with.

Work at full power

Even though preparation for production of the modernized IS-2 fell behind schedule, hull manufacturers started getting ready for the new order in June. According to decree #244s of the People's Commissar of Tank Production, factory #200 was instructed to produce four hulls with a straightened front and new turret platforms. UZTM began producing new hulls in May. According to ChKZ's correspondence, the first IS-2s with a straightened front and new turret platform were delivered in July.

UZTM's hulls triggered some complaints. All hulls had incorrect openings drilled for MK-IV observation devices and the suspension stops. The factory had to correct this, which resulted in decreased production volumes. The first complaints about reduced visibility began to come in in July.

The change to the front hull did not change the name of the tank. The name «IS-2 model 1944» was a post-war creation. The name IS-2M also has no connection with reality. The real IS-2M appeared in the late 1950s.

ChKZ reports do not differentiate between the two tanks. Occasionally the new design is called «IS-2 with a straightened nose». It's worth mentioning that some new tanks received old hulls as late as August of 1944. Production fully switched to tanks with the new hull on September 1st. Most of these came from factory #200.

ChKZ was behind schedule in August, and so work on August's batch only began on August 9th and ended on September 6th. The first tanks began to arrive at the acceptance workshop on August 11th. To speed up production shifts were extended to 18 hours and even security guards and firefighters were used in the assembly process. ChKZ reached the necessary production volume of 250 tanks per month in August.

Despite these extreme conditions, military acceptance testing reported that quality increased. The first tanks with no defects at all were delivered in August of 1944, making up 16% of the overall delivery. Defects that were spotted were low priority: bolts not completely screwed in, rough finish, etc. The new designs included better fitting transmission access hatches, locks for the emergency exits. Hulls produced by factory #200 even had special deflectors to prevent the hatches of those exits from being torn off.

ChKZ first made use of a fourth supplier in August of 1944. This was the Hammer and Sickle factory in Moscow. Its participation in IS-2 production is nearly unknown. According to initial plans made in May 1944, the factory was to deliver 30 turrets to equip UZTM hulls each month. The situation turned out differently. Only two turrets were cast in May, three were delivered in June. 18 turrets were delivered in July, and 9 were sent to UZTM. Serious production began in August of 1944, when Hammer and Sickle delivered 31 turrets, 23 of which were sent. Production plans for 1944 did not envision more than 30 turrets per month. With a total quota of 210 turrets in 1944 Hammer and Sickle cast 152, of which 131 were accepted and 103 sent to the customer. To compare, Mariupol factory was instructed to make 925 turrets, cast 978, and delivered 922.

In addition to UZTM, a small number of Hammer and Sickle turrets made it to factory #200. One tank with this combination of hull and turret can be seen at the Central Museum of the Armed Forces of the Russian Federation (serial number 240-412481, produced in February 1945).

Production of turrets at the Hammer and Sickle factory in 1945 was miserly. 25 turrets were delivered in January, 10 in February, 4 in March. In Mariupol 97 turrets were delivered in January, 104 in February, 73 in March, 54 in April. Production of IS-3 turrets was scheduled to start in May, but in reality the factory switched to T-44 turrets.

Turrets built in Moscow were similar to those produced at UZTM or Mariupol. Like turrets produced in Sverdlovsk, the Hammer and Sickle turrets had no casting number. Nevertheless, it is easy to tell them apart. UZTM turrets received ribs around the rear machine gun mount, which were not present on Moscow or Mariupol turrets. In addition, Moscow-made turrets had a straight mold line that ran horizontally along the turret and cannot be confused with any other sign. Moscow turrets also had a very coarse texture since they were cast in earth.

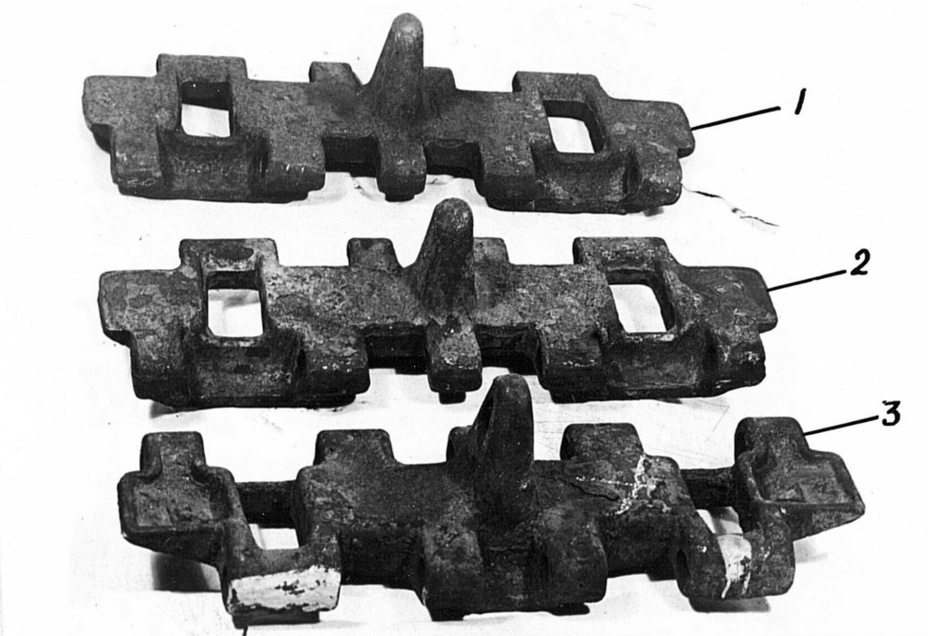

The work to streamline production made at UZTM in the summer of 1944 began to give fruit in September. In addition to meeting the quota, military acceptance staff at the factory remarked that production went much smoother than in August. The SB.2 assembly workshop finished production by September 29th and delivery by the 30th. The number of tanks delivered without defects reached 57 units. However, there were problems with some components, and the factory worked at correcting them. For instance, the situation with track links was difficult. IS tanks were supposed to transition from using stamped two-piece tracks to tracks cast from 27SGT steel. It turned out that these tracks often did not meet the 1000 km warranty requirement, and so stamped tracks were still common on the IS-2 and ISU. The biggest problem was the track pin eyes, which often tore. A new design was developed in September of 1944 which gave good results. However, this didn't change the production situation radically, and IS tanks and SPGs continued to be equipped with both cast and stamped track links.

Another issue was the road wheel axle cover. Trials of new road wheels with a grease nipple were performed in September of 1944. The NKTP ordered that this change be introduced into production, but the process was delayed since a new assembly line had to be set up. The V-11 engine also never made it onto this tank, but was used on the IS-3.

A travel clamp was added to the upper rear plate on September 1st. As of September 20th the tanks received a new inertial started with a SI-40 motor. Reinforced return roller carriers and locks on the emergency exit hatch were introduced in September as well.

The situation with heavy tanks in Chelyabinsk continued to improve in October. Of 250 IS-2 tanks delivered in October 1944 70 had no defects at all, and only 76 had more than 5 defects.

Work on improving the driver's vision was also underway. Two solutions were developed by mid-October. The first variant had a wider observation slit, and the triplex moved forward by 50 mm. The MK-IV observation devices were also moved. This solution reduced the dead zone to 6 meters and improved vision to the sides. The second proposal included an observation port and was not even considered. Based no correspondence, the first variant was approved, but never put into production, although the MK-IV periscopes were still moved forward in practice. The situation with vision improved, but the issue was not completely resolved. An extra observation device was installed on the IS-2M.

The factory delivered 250 vehicles again in November. Most of the work was done in the second 10-day period. ChKZ finally had a buffer of 50 sets of parts to begin December production in a timely manner. There were still issues with tracks. 18-20% of cast track links had defects, as well as 10% of stamped ones. 16-19% of road wheels had defects. However, the quality was increasing. All five vehicles sent to warranty trials completed them without serious complaints.

Further changes to the design were slight, except one made in November. On October 14th, 1944, Stalin signed GKO decree #6723ss «On installation of high caliber DShK AA machine guns on IS tanks and SPGs». In November 25 IS-2s were the first to receive DShK AA guns. The first AA gun mount was tested in early 1944 on the Object 244 (Object 237 with the 85 mm D-5T-85BM gun) but the design was too bulky. The new mount was much more compact and well built. It could easily be called the best AA gun mount of the war. The machine gun was installed on a pintle that was attached to the commander's hatch. Unlike foreign designs, the Soviet mount had a counterweight system and a sight that could be covered up during travel. Variants of this AA gun mount were installed on Soviet AFVs for decades. 125 IS-2s received this mount in December and all new tanks and SPGs received it starting in January of 1945.

The military acceptance staff noted that the increasing capacity of ChKZ allows it to produce up to 600 tanks and SPGs per month instead of the current goal of 500. However, there were still issues in December. Introduction of AA mounts resulted in a shortage of ball bearings. Issues with track links continued, and work on new links began again. The quality dropped, not a single tank passed the 300 km test run. Issues of factory #200 where volume of production of hulls and turrets dropped significantly compounded these problems.

Issues with the AA mounts continued into January 1945. There were not enough collimating sights and DShK machine guns. However, out of 250 IS-2s 216 passed acceptance trials on the first try, a very good result.

In February ChKZ began to prepare for production of the Kirovets-1 heavy tank, later accepted into service as the IS-3. 8 tanks were assembled in February, but they were not officially recorded, since they needed a lot of work. This did not stop design work from continuing. New cast and stamped track links were tested in February of 1945. They were made from TVM and DVLVT steel, the latter was used to make a lighter track. It turned out that stamped TVM tracks perform the best, but even cast KDLVT track links gave a lifespan of 1600 km. To compare, 32.4% of production 35HG2 track links broke during a 1600 km test run.

Introduction of new track links dragged on, but another important change was made on February 1st. MDSh smoke bombs were installed on the upper rear plate. The IS-2's look was finalized in February of 1945.

250 tanks were accepted in March, but a drop in quality was once again noted. Production began to wind down in April due to the start of production of the long-awaited replacement, the IS-3. Even though out of the 25 assembled vehicles in April none were accepted, the decline of the IS-2 began. 230 tanks were delivered in April, 155 in May (along with the first 100 IS-3s). The last five ChKZ IS-2s were delivered in June of 1945.

The price of the tanks dropped. In early January 1945 the price of one IS-2 was 280,000 rubles, in the second quarter of 1945 the tanks cost 250,000 each.

In total ChKZ delivered 3385 IS-2 tanks from December 1943 to June 1945. The last 63 tanks were delivered in June. Only one IS-2 remained at the factory for lengthy trials. In October of 1945, instead of handing off this tank (it needed major repairs) the factory delivered an extra IS-3.

Made in Leningrad

The story of the IS-2's production wouldn't be complete without mentioning how they were produced at the Leningrad Kirov Factory (LKZ). The decision to renew production of heavy tanks in Leningrad was made in May of 1944. This was linked to the success on the front. The Red Army completely removed the blockade of Leningrad in January of 1944. The front lines moved away from the city at a rapid pace after 900 days of encirclement. On May 26th, 1944, Stalin signed GKO decree #5959ss «On organization of IS tank and hull production, on the restoration of the metallurgy manufacturing at the Kirov and Izhora factories in Leningrad». The first 10 Leningrad-built IS-2s were awaited in October, 20 in November, 25 in December. Production was expected to reach 50 tanks per month in the first quarter of 1945. The decree also revived the Izhora factory, which would supply LKZ with hulls and turrets.

This decree had an impact not only at ChKZ, but at factory #200 and other institutions where engineers were evacuated from Leningrad. The production process was upset at factory #200, and this reflected on their output.

However, a decree and its execution are two different things. Leningrad not only lost about one million people during the blockade but was also largely destroyed. The Kirov factory, despite remaining active during the blockade, was heavily damaged. Most of its equipment was evacuated. The Izhora factory became a battlefield. Among others, the 72nd Independent Machine Gun Artillery Battalion commanded by reserve Lieutenant G.V. Vodopyanov and composed of former factory workers fought here.

The situation was a difficult one. The NKTP understood this, and the decree also instructed that equipment should be sent to the Kirov and Izhora factories, but the factories were not ready for production in the summer or fall. As of September 25th workshop MKh-3 at LKZ was still partially destroyed and in need of serious repairs. The remainder of the factory's workshops were in similar condition. Equipment was in a poor state. 54 new machines (including 26 imported) arrived at the factory. One IS-2 was assembled from components sent from Chelyabinsk. It was tested, but not accepted.

GKO decree #6706 was published on October 14th, 1944. According to this decree, LKZ had to deliver its first five IS-2s in December of 1944. Even this deadlines was impossible. By November 15th, 1944, the MKh-3 workshop had 160 various machines, but only 15 were set up. According to the factory's military representative Engineer-Colonel Rumyantsev, these machines were being used in vain. The factory prepared torsion bars for two months, but not a single one was delivered. It was not possible to complete them without sufficient half-stock. Steel furnaces, casting and rolling workshops, and the forging shop were ready to go. The factory had 11 thousand workers, but the military representative complained that nothing was done to begin production. The situation did not improve in December. It's not surprising that not a single IS-2 was shipped from Leningrad in 1944.

The light at the end of the tunnel only lit up in the spring of 1945. The factory finished its first five IS-2s in March. One of them was the tank assembled back in September of 1944. As strange as it sounds, all tanks built in Leningrad in 1945 had a summer 1944 design. All of these tanks had old style hulls and turrets built before the summer of 1944. Since the hull production was not set up locally, leftovers from factory #200 were used. These tanks also turned out to be very expensive, 350,000 rubles per unit. Documents from April indicated that the final delivery of the tanks will only take place in June. It seems that LKZ management understood that delivery of IS-2 tanks was not going well and ISU-152 production was doing much better.

Only 10 IS-2s were built in Leningrad: five were delivered in May, the March production tanks were only delivered in June. Heavy tank production finished after that. A second manufacturing base for heavy tanks never took off.

Translated by Peter Samsonov. Read more interesting tank articles on his blog Tank Archives.

Sources:

- Central Archives of the Russian Ministry of Defence;

- Russian State Archive of Economics;

- Russian State Archive of Socio-Political History;

- Kirill Koksharov's archive;

- Igor Zheltov's archive.