Modernization often starts immediately after a tank is accepted for service and put into production. The T-34 was no exception in this regard. A number of changes to simplify production and improve the tank's characteristics were made in the first year. The T-34 changed even more radically in 1941. For instance, the L-11 gun was replaced with the F-34 gun in March of 1941. There were also plans to improve the armour, but they were only partially realized. Let us discuss the applique armour used on T-34 tanks from 1941 to 1943.

Unavoidable reinforcement

A new stage in Soviet applique armour design began in the spring of 1941. In addition to work on applique armour for T-26 and T-28 tanks, designers received the task to develop applique armour for the KV-1 and KV-2 tanks. This was triggered by intelligence on new types of German tanks that was acquired in March of 1941. According to this information, German «Type V» and «Type VI» heavy tanks were equipped with 75 mm guns capable of defeating Soviet heavy tanks.

Decree #548-232ss was signed by the Council of People's Commissars and the Central Committee of the Communist Partyon March 15th, 1941. It required to produce prototypes of KV-1 and KV-2 tanks with applique armour by May 1st and put them into mass production by June 1st. This work was only a temporary solution. In the summer, KV tanks with thicker main armour would enter production. This plan was put into action, but only for the KV-1, as the KV-2 was already overloaded. Even though German heavy tanks did not show up on the Eastern Front in 1941, the idea of thickening the armour was correct.

Another one of the Red Army's new tanks received applique armour, the T-34. This happened later and for different reasons, and was not because of the intelligence informtaion.

Two hulls and two turrets were shot up at the Mariupol factory between April 1st and April 12th, 1941. The guns used were the 37 mm Polish Armata przeciwpancerna 37 mm wz. 36 Bofors, 37 mm model 1930 anti-tank gun, two 45 mm model 1937 anti-tank guns, and the 76 mm divisional model 1902/30 gun. It turned out that parts of the hull can be penetrated by 45 mm sharp tipped armour piercing shells from up to 600 meters. The sides were most vulnerable. The front of the hull was the most resistant and even withstoof 76 mm hits, but even it had weak zones.

45 mm thick armour no longer seemed like enough.

This was not news for factory #183's design bureau and the GABTU. Tactical-technical requirements for a «T-34 tank with a T-60 torsion bar suspension» (later T-60 was corrected to T-34-T) were approved on March 5th, 1941. The number 60 stood for 60 mm of front armour. It was already known that 45 mm of armour did not give complete protection from the 45 mm gun.

The story with the reinforcement of the T-34's armour continued in April of 1941. A proposal was made to increase the thickness of all front armour to 60 mm. The floor armour was thickened from 20 to 30 mm. This tank was called A-43.

The issue of reinforcing armour on ordinary T-34s was also raised. Decree #1216-502ss of the SNK and Central Committee «On production of T-34 tanks in 1941» was issued on May 7th, 1941. It raised the issue of producing the A-43 and T-44 (A-44) tanks. The 10th paragraph of the decree is the most interesting in this context.

«It is ordered that:

- The People's Commissar of Medium Manufacturing (comrade Malyshev) and director of factory #183 (comrade Makrarev) jointly with the People's Commissariat of Defense (GABTU) are to produce and test two prototypes of T-34 tanks with additional armour of the turret and front plate, 13-15 mm thick, in June. Install applique armour of 500 T-34 tanks already in service by sending out brigades with instruments and materials.

- The People's Commissar of Shipbuilding (comrade Nosenko) and director of Mariupol factory (comrade Garmashev) must produce armour plate for applique armour of two T-34 tanks within two weeks of receiving blueprints from factory #183.

- The People's Commissariat of Defense (GABTU, comrade Fedorenko) must organize bases for installing applique armour on T-34 tanks, equipping them for welding and mechanical work, and supplying auxiliary workers.

STZ and factory #183 are to begin production of tanks with applique armour starting in August of 1941.

The Mariuopol factory is to begin supplying factory #183 with applique armour parts in July of 1941.

Factory #264 is to begin supplying STZ with applique armour parts in July of 1941."

This applique armour did not exist even as a draft at the time this decree was signed. Factory #183 had yet to design them. The armour department of NII-48 was also involved in the work. Some publications claim that the applique armour was developed in May of 1941, but that is not so. According to the summary report on experimental work, the blueprints were still being developed in May. Instead of 15 mm thick plates, the factory used up leftovers from BT-7 production, which were 13 mm thick. By the start of June, it was not yet decided if the armour would be attached with welding or bolts. The factory preferred bolts with a space of 25 mm between the main armour and applique armour. The first trials were performed in May. It turned out that the ballistic limit (the impact velocity of the shell needed to penetrate the armour) increased by 40-55 m/s.

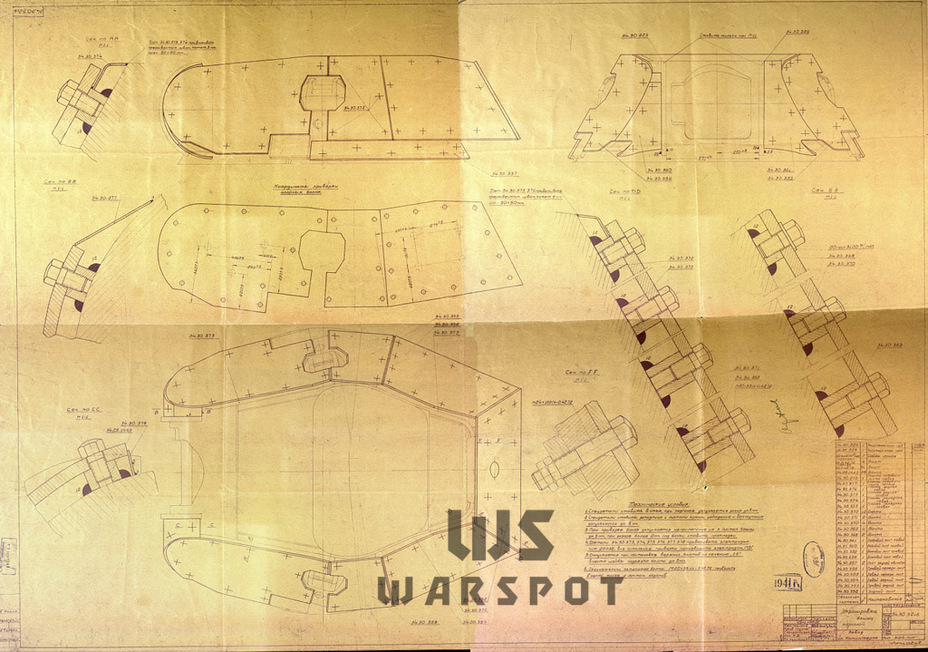

Documentation on the applique armour was ready by mid-June 1941. As before, the applique armour was bolted to carriers, which were welded onto the main armour. The front of the hull was protected by four plates on the top and two on the bottom. This layout was the simplest to produce and allowed to quickly replace the armour in case it was damaged. The connecting beam did not have additional armour, but there was a variant of the armour developed for tanks without a beam. The turret was reliably protected. Extra armour was installed along its perimeter and protected the turret ring as well as the main armour. The total mass of the applique armour was 1050 kg according to calculations.

As required, two tanks were equipped with applique armour. These were tanks with serial number 0618-7 (1940 production with L-11 gun and no connecting beam) and 811-28 (1941 production with an F-34 gun and connecting beam). This was done in July, not June. 120-140 man-hours were required to convert one tank, which was within norm for this kind of work.

To figure out how this change affected the tank's characteristics, a third tank (#311-25-3) was loaded up to 28.5 tons and tested in spring-summer of 1941. No exceptional issues were discovered after a 1697 km march. However, the general drawback of tanks with applique armour showed itself. The front of the tank dipped significantly when driving on bumpy roads.

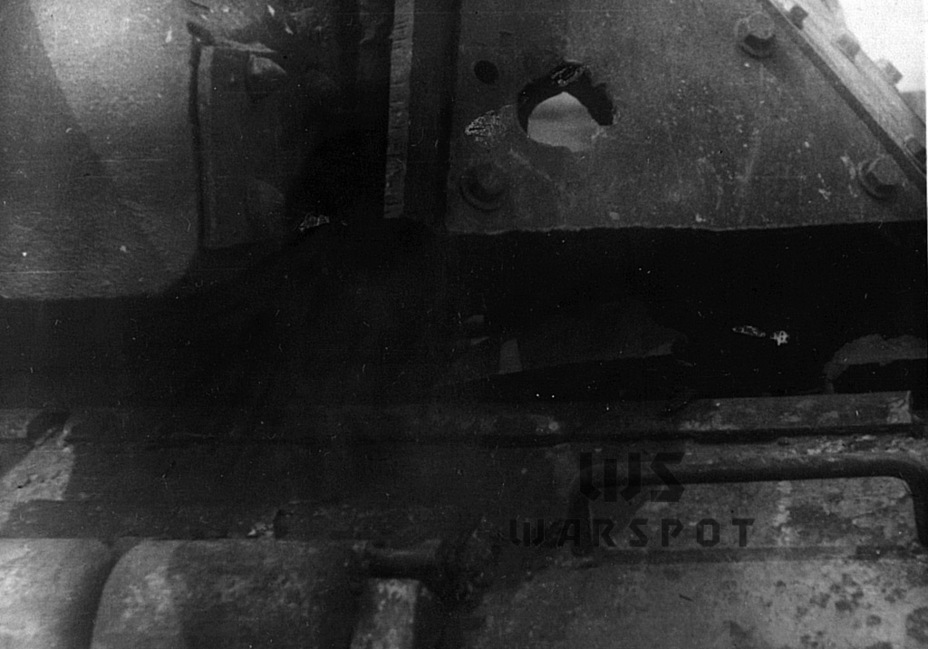

The widespread opinion that the applique armour project was cancelled because of the start of the war is incorrect. Yes, hull production facilities were overloaded, but there were also many issues with the applique armour design. The attachment by bolts was unreliable, as the first hit from a shell would break them off. The design with mudflaps was also complicated.

The applique armour was to be changed. The armour would be installed without spacing, and would be attached by welding. The sloped sides around the fighting compartment would also receive additional armour. NII-48 also had its complaints. They noticed that the armour does not cover the most vulnerable parts of the front of the tank: the driver's hatch and hull machinegun. However, these components were not covered on any subsequent applique armour design either.

In any case, the design developed by factory #183 was rejected. It would not have gone into production in any case. Both tanks with the applique armour were sent to the front lines. The tank with an F-34 gun even popped up in a front line photo.

Second coming

A lull took place after factory #183's design was rejected in July of 1941. Unlike the KV-1, the T-34 never received thicker main armour. The tank continued to be produced with 45 mm thick plates. The issue of applique armour arose once more in the fall of 1941. This was triggered by the analysis of use of the T-34 in combat and captured German memos on combat with Soviet tanks.

This information coincided with the findings of spring 1941. The front of the tank was the toughest part, but the lower sides could be penetrated by light anti-tank guns from 400 meters and closer. The situation with the 50 mm Pak 38 was even worse. The T-34's side could be penetrated from 700 meters. The 105 mm leFH 18 howitzer could also penetrate the side from that distance.

A proposal was made in October of 1941 to install applique armour along the sides. The sloped part of the side would be covered with a 15 mm plate, the suspension covered with 25 mm thick spaced armour. The turret ring would be protected from the sides and front to prevent jamming. To compensate for the increase in mass, smaller road wheels with internal shock absorption would be used.

In practice, work on up-armouring T-34 tanks went in a different direction. The production of the A-43 was a pipe dream by the fall of 1941, so a decision was made to improve the existing design. Even though results of trials showed that it was necessary to increase the sides of the hull, the front armour of the tank still came under the most frequent attack. It was decided to reinforce that part.

A technical meeting was held at factory #112 in mid-November 1941 to discuss this question. This topic was mentioned several times in the NKTP. On December 25th, 1941, Stalin signed GKO decree #1062ss «On T-34 and T-60 tanks». According to this decree, all T-34 tanks were to be produced with applique armour increasing the total thickness of the front armour to 60 mm from January 15th and 60 mm thick main armour after February 15th.

By this point, three factories were producing the T-34: Stalingrad Tractor Factory (STZ), factory #112 (Gorkiy), and factory #183 (Nizhniy Tagil). Factory #183 remained the chief factory, but by the start of 1942 all three factories were producing noticeably different tanks. Factory #183 began producing a hexagonal turret with some features from the A-43 turret (gun mount, separate round hatches, etc) due to technical difficulties with the old design. The hulls also had their differences. STZ and factory #112 tanks also differed. With time, these differences only increased.

Factory #183 had their own approach to decree #1062ss. According to a letter sent on January 3rd, only the front of the hull would receive applique armour. The protection of the turret was improved by increasing the thickness of the main armour to 60 mm. Considering that the turret was cast, and that 52 mm of cast armour was considered equivalent to 45 mm of rolled armour, this was not enough protection. In practice, turrets were still cast with 52 mm armour.

Factory #112 developed a scheme where the front of the hull and the front (and partially sides) of the turret were covered with additional 15 mm thick plates. Like the factory #183 design, they were welded on. This design used small sheets of armour.

In Stalingrad, the development of applique armour was taken up by the supplies of hulls and turrets: factory #264. This factory also developed a layout with improved armour in the front of the hull, the front of the turret, and partially the sides of the turret. Recall that factory #112 mainly used cast turrets, and factory #264 mainly welded ones.

Factory #183 was the first to begin producing tanks with applique armour. Production began on January 20th, 1942. Factory #112 began producing turrets with applique armour on February 1st, factory #264 started on February 2nd. By February 17th factory #264 produced about 120 such hulls and turrets. Factory #112 was not doing as smoothly: only 80 hulls and 109 turrets were made. Either way, T-34 tanks with applique armour were being made by the hundreds in February of 1942… but on February 23rd, Stalin signed GKO decree #1333, cancelling the applique armour. The hulls and turrets that were already produced could be used up to make tanks.

Why was the installation of applique armour cancelled? On January 21st, a draft of a GKO decree titled «On production of T-60 and T-34 tanks with thickened and applique armour» moved the due date for starting production of tanks with applique armour to February 10th and the due date for tanks with thickened hull armour and applique armour on the turret to March 10th. After April 1st, all armour would have to be thickened. However, in February of 1942 it was clear that thickening rolled armour is not the way to go. Factories that were overloaded with orders and struggling with production difficulties would not be able to transition to 60 mm plates. As for the applique armour, it took up a lot of time, effort, and resources.

The biggest reason was that the benefit from this armour was not that significant. Leftover hulls and turrets were slowly used up. For instance, STZ tanks produced in the summer of 1942 still had these hulls.

Factory #112 had to go back to applique armour. The problem this time wasn't that the armour was too thin, but armour plates that were supplied were defective. These defects were common in 1942, especially when it came to the upper front plate. This was a complicated piece with many cutouts. Because of this, applique armour was installed. These were patches rather than full armour plates, but they spanned the entire width of the hull. It had a different shape than earlier designs and was often made from one large sheet of steel.

Protection from «thermite shells»

The topic of applique armour for the T-34 came up once more in the end of summer of 1942. The Germans began to use a new type of ammunition, HEAT, or as they were sometimes called, «thermite shells». They were first used against tanks in late 1941, but their application was much more common starting with 1942. This type of ammunition increased the effectiveness of short barreled guns on the StuG and PzIV. According to Soviet data, a HEAT shell could penetrate 45 mm of armour from 1000 meters. The use of subcaliber ammunition was also noticed.

Another unpleasant surprise came from the NII-48. Having analyzed the use of the T-34 in combat for May-July of 1942, they came to the conclusion that 50.5% of hits come at the sides.

The GABTU initiated work to create spaced armour to protect from these kinds of shells. Nobody was talking about applique armour for the front anymore. It was clear that other parts of the tank needed protecting.

A meeting was held at factory #112 on September 12th, 1942, discussing protection from new types of ammunition. Representatives of the NII-48, factory management, and a representative from the GABTU, Engineer-Lieutenant Colonel M.A. Burtsev were present. Engineer A.T. Larin from NII-48 proposed placing the applique armour some distance away from the main plate, at least as far as the length of a subcaliber penetrator. As for HEAT rounds, experiments would have to be held. It was decided that experiments with various ways of attaching the spaced armour and various distances away from the main armour would have to be carried out.

Trials were held at the Gorohovets ANIOP proving grounds from September 25th to October 9th, 1942. Various plates were installed on top of the T-34's main armour, both right up against the armour or some distance away. It turned out that 10 and 20 mm thick screens without any spacing are easily penetrated by HEAT ammunition fired from either the Soviet 76 mm regimental gun or the 75 mm KwK L/24 in a PzIV Ausf.E.

The best results were shown by 5 and 20 mm thick plates installed at a distance of 425-480 mm from the main armour. This combination could not be penetrated. It also turned out that the turret was more resistant to HEAT shells than the sides of the tank, even without spaced armour. A low lifespan of spaced armour was also discovered during trials. A 16 mm thick spaced armour plate was destroyed after two hits from subcaliber shells or three hits from HEAT shells.

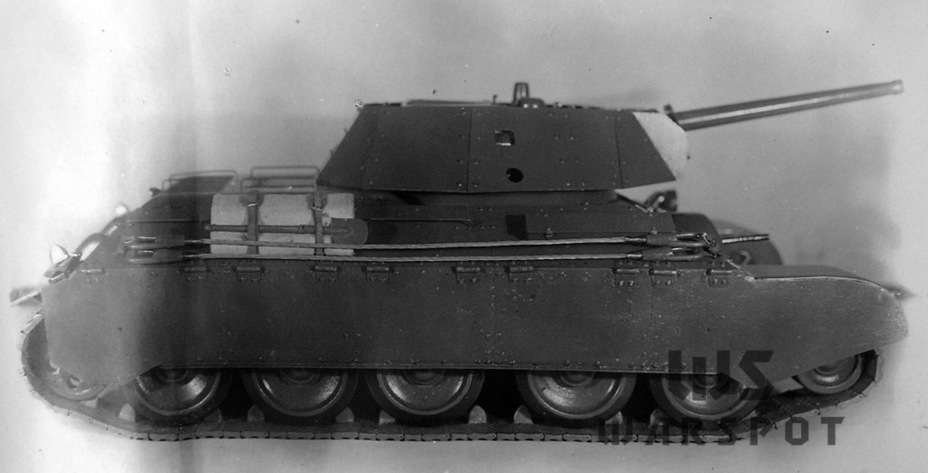

After studying the results of the trials, factory #112's design bureau developed a spaced armour project for the T-34 under the direction of V.V. Krylov. Since the plates had to protect the tank from HEAT and subcaliber ammunition, they had to be thick, and therefore heavy. The main proposal consisted of 20 mm thick plates, the heaviest type considered.

According to the project, the sides, suspension, front hull beam, sides of the turret, and partially the front of the turret were protected. There was also a lightened variant without protection of the turret. Five variants with different levels of protection were offered. The mass of these tanks ranged from 31.8 tons to 32.19 tons. A T-34 without extra armour weighed 28.63 tons.

The spaced armour was held on with bolts combined with Belleville springs. To make working on the suspension easier, the spaced armour that covered it was installed on hinges. If necessary, it could be easily disconnected and flipped up.

The list of proposals included a number of modernizations, including changing of the slope of the main armour. However, they were presented as reserve variants, since no one would change the hull so radically in wartime.

A compromise was accepted by the GABTU. The 20 mm plates offered better protection, but the increase in weight was too much. 16 mm thick plates were used. The tank would be built in two variants. The first increased in mass by 2622 kg, but both the hull and turret were protected. The second protected only the hull, but was lighter: the mass increased by 1833 kg. In the second case, plates that were 10 mm thick were used in addition to 15-16 mm plates.

A report on applique armour was presented to Stalin on November 19th. It proposed building 46 T-34s with applique armour: 23 of the first type and 23 of the second. This proposal was approved. On December 7th, 1942, Stalin signed GKO decree #2594ss, ordering factory #112 to produce these tanks by March 1st, 1943. They were all built in the spring of 1943.

The tanks were sent to the 139th and 198th Tank Regiments. The Commander of Armoured and Mechanized Forces of the Red Army ordered the tanks to the front line to be tested in battle conditions by order #064 given on June 9th, 1943. Units equipped with the spaced armour T-34s were sent to the 41st Tank Brigade of the 5th Tank Corps and 111th Tank Brigade of the 25th Tank Corps. The 139th regiment had 21 T-34 tanks with the first type of spaced armour and 11 T-34 tanks with the second type. The 198th regiment had two tanks with the first type, 12 tanks with the second type, and 18 T-34 tanks from factory #112 without any spaced armour at all.

A number of suspension and drivetrain defects were discovered during the march to the initial positions, but these defects were also present on T-34s without spaced armour. The downside exclusive to tanks with spaced armour was decreased performance on bad terrain. This happened because mud would get packed between the main armour and spaced armour during turns. Other than that, the spaced armour had almost no effect on off-road performance and maneverability.

Brigades equipped with spaced armour T-34 tanks took part in the fighting from July 25th to August 8th, 1943. By the start of the offensive, the 41st Tank Brigade had 89 T-34s and 10 Valentines. On July 28th, the unit went on the attack to chase the enemy out of Rudnevo. The enemy met the tank attack with fire from tanks, SPGs, and anti-tank guns. The brigade managed to take the village at a cost of 7 tanks. It turned out that the spaced armour resists 75 mm HEAT shells well, but not 75 mm AP shells. Even worse, the Germans were using new 88 mm Pak 43/41 guns. The brigade also took heavy losses on the next day.

The 41st Tank Brigade fought its way through 35 km of enemy territory and completed its objective. However, tanks with spaced armour took the most losses. Only 2 tanks with the first type of spaced armour and 5 with the second remained functional. 14 tanks were lost irreparably, 5 required major repairs, and 6 required medium repairs.

The 111th Tank Brigade had 5 functional tanks with spaced armour left. Thanks to fighting in lower intensity battles and having fewer tanks with spaced armour, losses in spaced armour tanks were also less. Two were lost irreparably, two more needed major repairs (all with the second type of spaced armour). Five more tanks (of those, one had the first type of spaced armour) needed medium repairs.

The analysis of damage taken in combat was even more disappointing for the tanks with applique armour. Only two hits each of 50 mm AP and 75 mm HEAT were discovered. Most of the hits (37) came from 75 mm AP, of them 16 hit the sides of tanks, 5 hit the upper side, 6 the front of the hull, and 10 hit the turret. 15 hits from Pak 43/41 guns were counted, 7 in the side, 3 in the upper side, 2 in the front, 2 in the rear, and 1 in the turret. In total, 24 shells his the side and 9 hit the upper side. Yes, the idea of protecting the sides was correct. However, the spaced armour was ineffective against 75 mm and 88 mm AP rounds. The spaced armour was also not enough to resist 50 mm AP.

The results of the use of the T-34 with spaced armour in combat were compiled into a report on September 25th, 1943. The authors proposed that the NKTP should develop more reliable protection for the sides of the tanks. However, at that point even heavy tanks were not reliably protected from the Pak 43. This batch of T-34 tanks from factory #112 was the last massed use of tanks with spaced armour by the Red Army. Work on applique armour continued, but remained experimental.

Translated by Peter Samsonov. Read more interesting tank articles on his blog Tank Archives.

Sources:

- Central Archives of the Russian Ministry of Defence;

- State Archives of the Russian Federation;

- Russian State Archive of Socio-Political History;

- Russian State Archive of Economics;

- Author's photo archive;

- Archive's Igor Zheltov;

- Russian State Archive of Film and Photo Documents.