Sverdlovsk (modern day Yekaterinburg) was the cradle of Soviet wartime SPG building. The concept of light and heavy assault guns (SPGs) was developed here. However, neither the light nor the heavy SPGs developed here were put into production. One of the reasons for this paradox was the publication of GKO decree #2120 ''On the organization of T-34 production at the Uralmash factory and factory #37''. According to this document, Sverdlovsk was to produce T-34 tanks instead of the T-70 tank, on which all of their light SPG designs were based. The SU-31 and SU-32 SPGs were left without a production base. All work on SPGs was transferred to factory #38 in Kirov. This was the start of the tragic history of the SU-12 (SU-76).

On factory #37's design

The factory #38 design bureau could not report of any new serious development by the fall of 1942. This is not surprising, as it did not receive any orders to develop new tanks or SPGs. However, the design group headed by M.N. Schukin had certain projects of their own. For instance, in the fall of 1941, before the evacuation from Kolomna, the factory design bureau developed a cast turret for the T-30 tank, and even produced an experimental batch.

In addition, in May of 1942, designer A.A. Chirkov created a light tank project with Schukin's assistance. The tank, designed in two variants, would be equipped with two M-11 aircraft engines. The design used a T-34 suspension and transmission. The tank was armed with a duo of 45 and 20 mm cannons, as well as a DT machinegun. The first version of the tank, weighing 14 tons, had 10-45 mm of armour. The second had thicker armour, 20-65 mm.

Work did not proceed past a draft project. No blueprints were preserved. At the time, the factory and design bureau's main objective was the production of the T-70 tank, not development of new vehicles. However, work on producing track links from steel alloy #40 instead of Hadfield steel was successful. The joint development of chief metallurgist Nosvkov and NII-48 went into production in December of 1942.

The work on light SPGs at the factory #38 design bureau was, in many ways, auxiliary. S.A. Ginzburg was the main ideologue of the SU-31 and SU-32, and he remained the chief designer of the new SPG in Kirov. Schukin's group merely put the designer's ideas into metal. This relationship was taken into account during the investigation in the spring of 1943. Unlike Ginzburg, who was sent to the front lines, Schukin and his group were not punished.

Work on an SPG did not begin in Kirov right away. A chassis had to be chosen for the new SPG. As trials of the SU-31 showed, the parallel engine layout had an advantage over the SU-32, which was based on T-70 components. Trials performed at the NIBT proving grounds were completed successfully on September 28-29th, 1942. Here it was discovered that the off-road performance of the SU-31 and T-70 was identical. However, the engine of the SU-32 overheated. Ginzburg himself was a proponent of the parallel engine layout. It is not surprising that the SU-31 was eventually chosen as the starting point for a new SPG.

Unfortunately, certain peculiarities were ignored during the chassis selection process. For instance, the fact that the SU-31 was built using the components of the T-60 small tank, while the SU-32 used T-70 components. The SPGs also served a different purpose: the SU-31 was a SPAAG, and the SU-32 was an assault gun. The armour was different as a result.

Tactical-technical requirements for the SPGs were formulated on October 16th, 1942. They were largely the same as those for the SU-31 and SU-32. This seems rather odd, given that the parallel engine layout was chosen. In addition, there were requirements for a third vehicle: an SPG on the T-70 chassis. GKO decree #2429 «On the production of experimental prototypes of SPGs» was signed on October 19th. According to it, the prototypes were due by November 20th. Only the Gorkiy Automotive Factory (GAZ) began working on all three variants. The vehicles were indexed GAZ-71, GAZ-72, and GAZ-73.

However, the GAZ assignment was largely a backup plan. The vehicles developed at Kirov were the priority. The SPAAG received the index SU-11 and the assault gun SU-12.

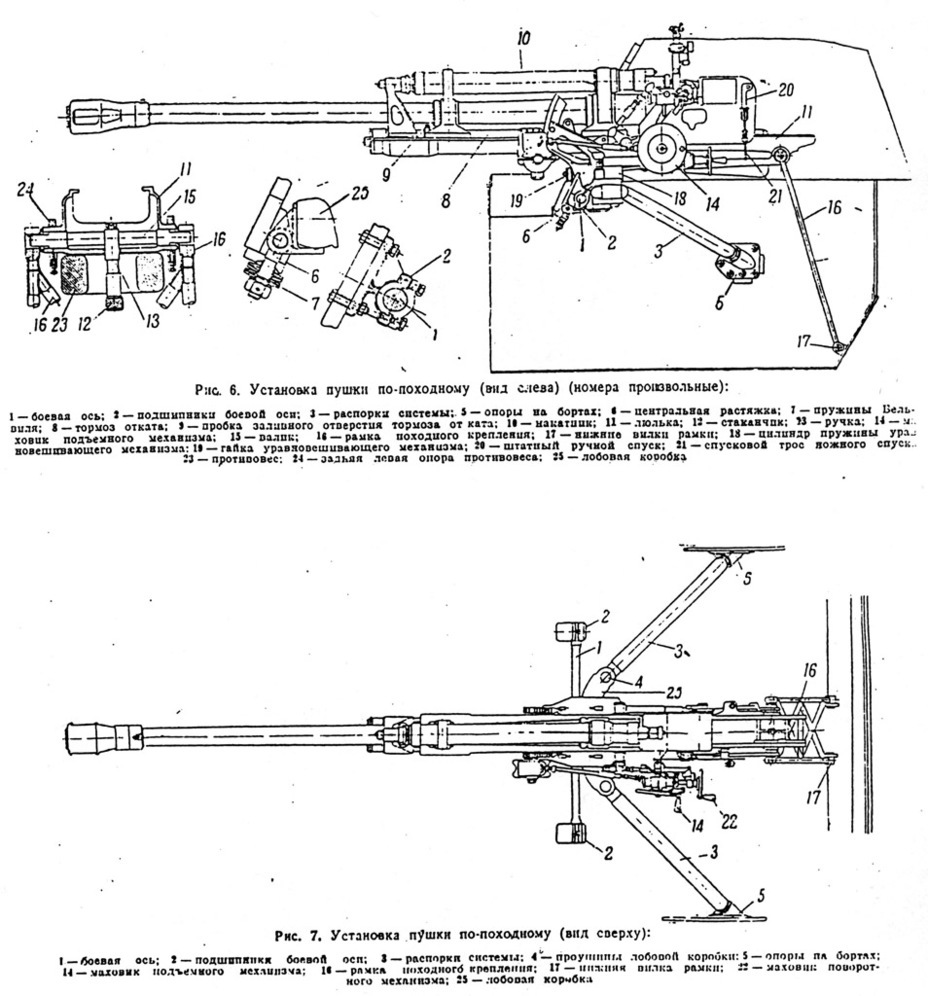

The main project was the SU-12: an assault gun with a ZIS-3 cannon. The installation of an IS-1 (altered ZIS-2) anti-tank gun was also considered, but never put into practice.

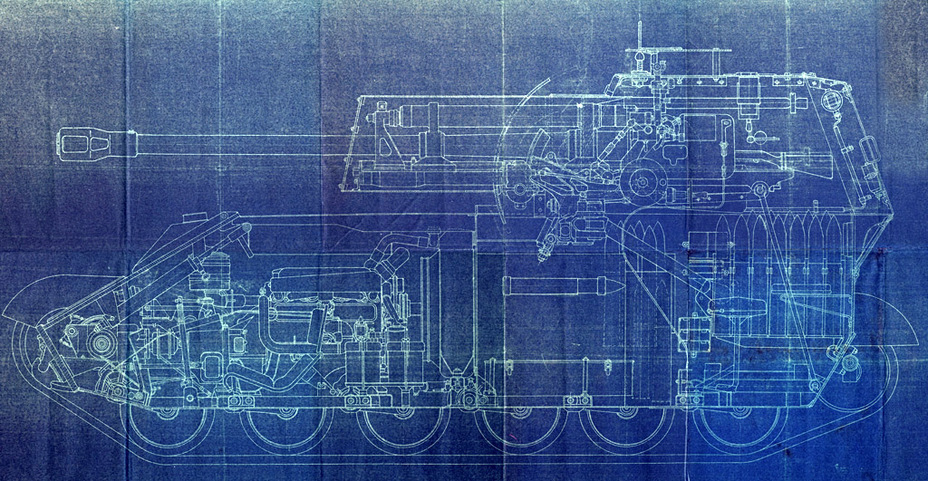

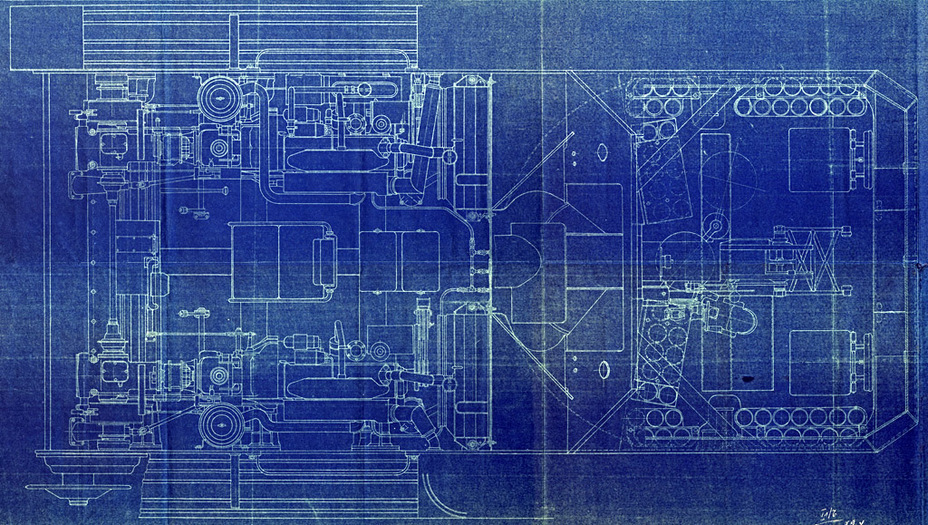

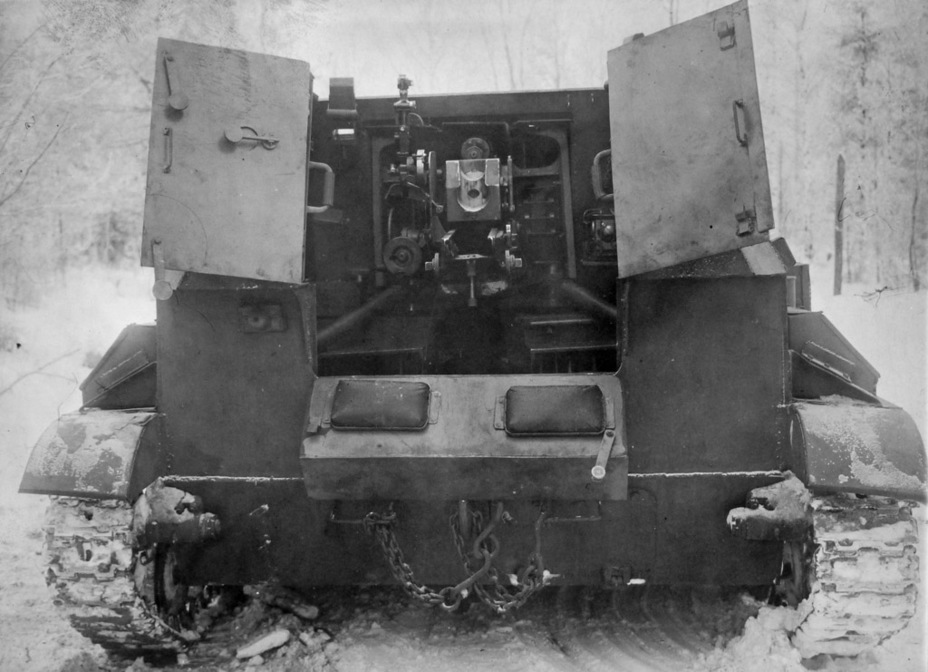

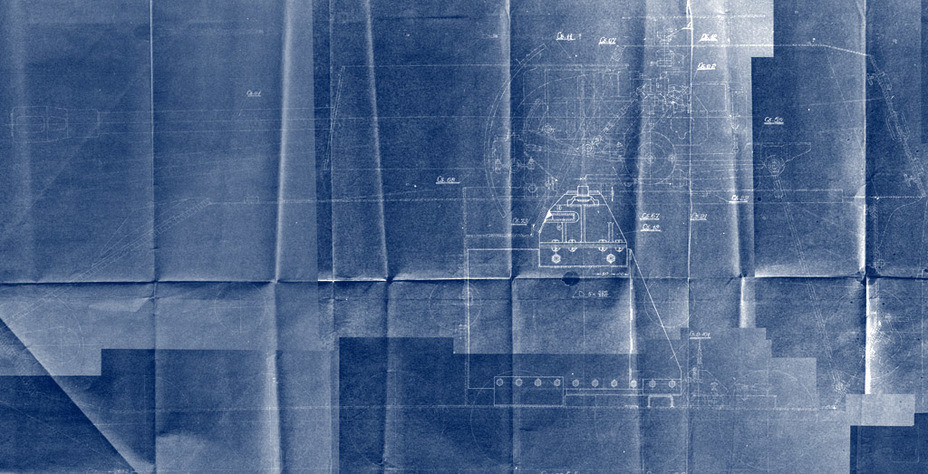

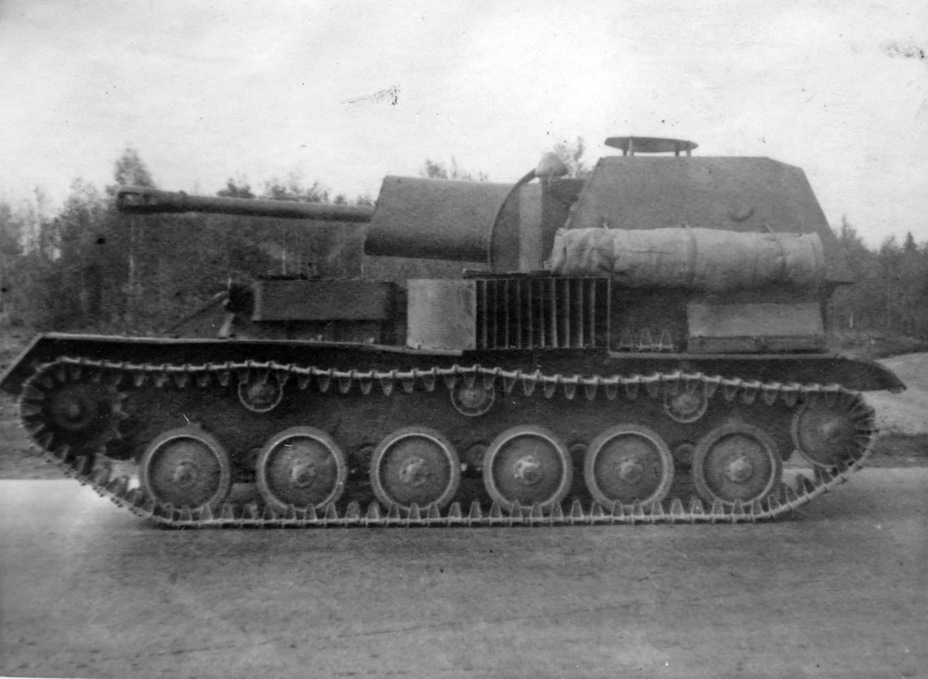

Even though the overall concept of the Sverdlovsk SPGs did not change, the design produced by Ginzburg and factory #38 was rather different. The design of the T-70B tank was chosen as the starting point. This modernized T-70 tank entered production in October of 1942. In addition to lengthening the hull and adding a sixth road wheel the chassis used a seventh road wheel as an idler, but without the rubber rim. The hull of the SU-12 was analogous to the SU-31 concept. The cooling system and engine air intakes were designed similarly. A number of components were taken from the T-70B as is, including the driver's hatch. The hatches on the upper front plate used to access the transmission as well as two hatches for engine starters allow us to distinguish this vehicle from the later SU-15M.

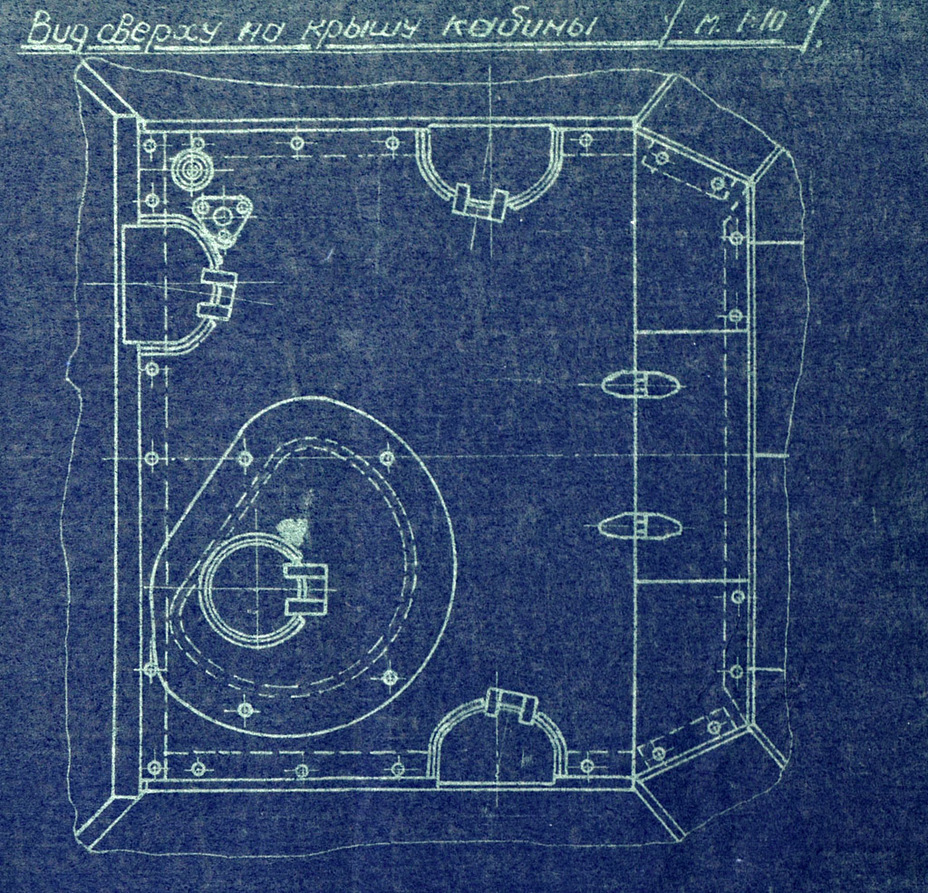

The fighting compartment was changed compared to the predecessor. The SU-32 was deemed too cramped, plus the machinegun was clearly superfluous. As a result, the casemate was completely reordered. It became much roomier, and the crew was better protected. Pistol ports covered with shutters replaced a machinegun ball mount. The rear of the casemate changed. It was now equipped with a three-piece hatch. The casemate was also enlarged, as the fighting compartment now had to fit three crewmen instead of two. The vehicle received a 9-R radio. Observation devices along the perimeter improved the visibility.

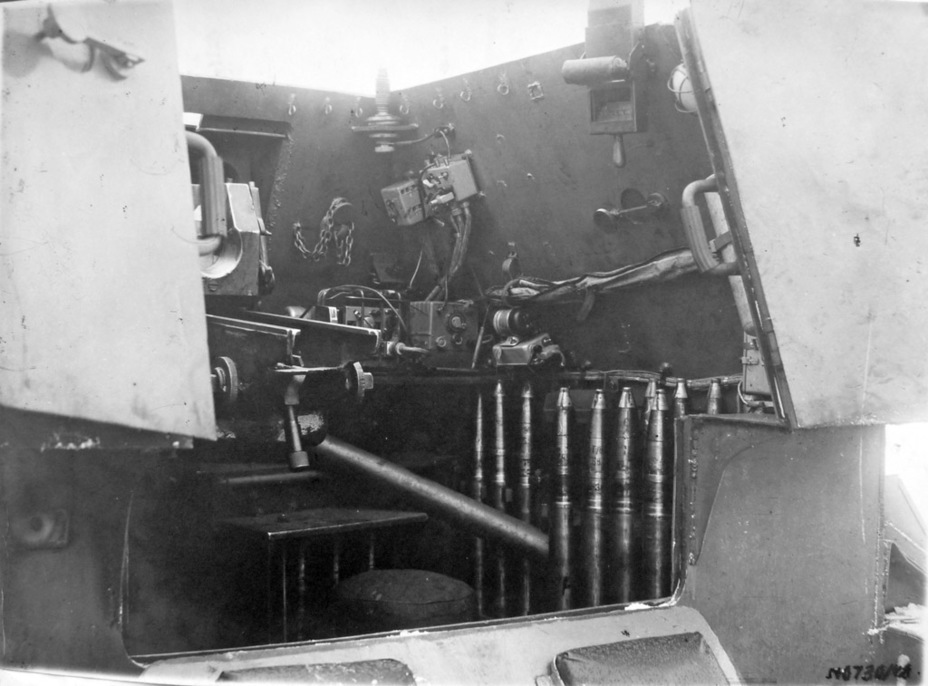

The gun remained the same. It included not just the oscillating part of the ZIS-3 76 mm gun, but also a part of the mount with truncated trails. The trails ate up some of the room in the fighting compartment. The gun mantlet was different than the one on the SU-32: it offered better protection and was simpler to produce.

The SU-11 SPAAG was designed in parallel with the SU-12. The designers didn't reinvent the wheel, but simply took the SU-12 chassis. The development of the AA gun mount was secondary to the design of the chassis. Only the fighting compartment changed: a platform similar to the one used on the SU-31 was installed instead of a casemate. Overall, the design was good. Changes compared to the SU-31 platform were minimal.

Into production with a defect

The plans approved by the GAU required completion of the SU-11 and SU-12 prototypes by November 15th, 1942. A trials program was approved on October 29th. Engineer-Major Getmanov was supervising the assembly of the SPGs at factory #38.

Considering that factory #38 had never worked on SPGs before, this deadline was quite harsh. Even though the Kirov workers approached the task very seriously, the deadlines were not met. However, the SU-11 and SU-12 were finished and began trials by November 21st. Factory mobility trials were completed by the 27th. The SU-11 had travelled 100 km and the SU-12 112 km.

It took a while to send the two SPGs to the Gorohovets ANIOP. Both vehicles wee only sent on December 5th. Nevertheless, it was clear which vehicle was the leader in the race for the light SPG program. Stalin signed GKO decree #2559 ''On organization of SPG production at the Uralmash factory and factory #38'' on December 2nd.

This document contained the following:

''The People's Commissar of Tank Production (comrade Zaltsmann) must:

<…>

b) organize production of the SU-12 SPG based on the T-70 tank with a 76 mm ZIS-3 gun at factory #38 (Kirov), removing the T-70 from production as of January 1st, 1943

2. Ratify the following production quotas for T-34 tanks, T-70 tanks, and SU-35 and SU-12 SPGs:

<…>

b) factory #38:

T-70:

- December 1942: 200

The T-70 is removed from production as of January 1st, 1943.

SU-12:

- December 1942: 25

- January 1943: 150

- February 1943: 200

- March 1943: 200''

The trials were also scheduled to go through. Having two vehicles on one chassis allowed the testers to establish its reliability. As further events showed, the situation with the SU-12 and (partially) SU-11 was far from stellar.

Trials began on December 6th with determining the gunnery characteristics. The SU-12 made 64 shots with a rate of fire of 12 RPM. Good stability and satisfactory groupings were observed. Overall, the vehicle was deemed successful. However, the fighting compartment of the competitor SU-71 (GAZ-71) had some advantages. The gun mount was less bulky, the trails did not protrude, and the travel lock was better.

Mobility trials began on December 9th. The SU-71 broke down and did not take part. As for the SU-12, mechanical issues did not bug it in the first days. However, enlarged mudguards had to be installed, since the snow that was being kicked up made it impossible for the driver to see. The same was done to the SU-11, which was going through trials in parallel.

On the 11th, after the march began, an oil leak into the cooling system was found. The issue was corrected, and the march continued. The SPG travelled 300 km during trials, but greater problems were coming. A serious breakdown of the right engine's gearbox occurred on the 400th kilometer. A portion of the mobility trials had to be done on one engine. A similar breakdown happened on the SU-11 after 350 km. The SU-12 failed trials.

The conclusions made on December 18th said the following:

1. The 76 mm SPG designed by factory #38 is a new type of artillery weapon, capable of supporting infantry and mechanized units with artillery fire during an offensive, solving the type of tasks that are assigned to 76 mm guns.

2. The vehicle presented for trials passed gunnery trials, but did not pass mobility trials, and cannot be recommended for service without the correction of the listed defects. After the defects are corrected, it must be submitted to 500 km reliability trials. The commission deems that if these trials are successful, then the SPG can be accepted into service with the Red Army.

A technical meeting took place at factory #38 on December 15th. Issues regarding the ZIS-3 were discussed, including ideas for how to lighten the system. A 100 kg counterweight was installed to compensate for the mantlet. The travel lock issue was also discussed. The side observation devices were removed, and only the commander retained his periscope. The driver's observation device became immobile.

The situation with the gearbox was interesting. Ginzburg prepared a memo addressed to the People's Commissar of Tank Production, Zaltsmann, on December 18th. In it, he blamed the poor gearbox gear switch synchronizer on the defects of the SU-12. According to him, poor quality assembly of the SU-11 and SU-12 was the cause of the issues in the trials.

Ginzburg was partially correct. Experimental prototypes built in wartime often had issues with quality of assembly. For instance, poor quality of assembly was what killed the KV-13 in its initial form. However, the KV-13 had plenty of design flaws.

The same was true for the SU-11 and SU-12. The chief designer should have taken note of the similar defects on both prototypes. However, the GKO decree already ordered the vehicles to be put into production. Ginzburg thought that it would be enough to correct the issues later. For now, getting rid of manufacturing errors would be enough. Claiming that similar issues were observed on the T-60 and T-70, the chief designer set off to Kirov to personally oversee the assembly process of the prototypes. This approach was effective. Even though training units reported mechanical defects in January of 1943, none of them had to do with the gearbox. It seems that the defect was defeated. In reality, Ginzburg just signed his death sentence, as his efforts only postponed the widespread breakdowns of the gearbox on his SPGs.

Cover up

While trials of the SU-11 and SU-12 continued, factory #38 was getting ready for production. As soon as the production of the T-70B for December was complete, the SPG took its place. The first 25 SPGs were finished in Kirov by the end of December. Externally, there were no differences from the prototype. The difference was in a lack of side observation devices and a few other improvements. As for the SU-11, its fate was a sad one. The high priority of the SU-12 meant that the SPAAG was forgotten. It was simply omitted from production plans.

Reliability trials of SU-12 #L212602 were performed on December 29-31st. The SPG drove for 500 km without a gearbox breakdown. It seems that the issue was indeed in the quality of manufacturing, and improvements to the process solved it once and for all.

The most famous change to the SPG, implemented during the production, was the introduction of a roof. At first, the SPG was open from the top, like its predecessors and competitors. Correspondence found in the economics archive (RGAE) indicates that Stalin requested a roof personally. The 6 mm thick roof had three openings for periscopes and an opening for a panoramic sight. The roof was introduced because the crew in the fighting compartment was vulnerable to bullets and shell splinters. The correctness of the roof was proven by the first battles that the SU-12 participated in. The Volkhov Front, where these SPGs were first used, sent a message requesting that roofs be installed.

Roofs were scheduled to be introduced into production in January of 1943, but due to a lack of 6 mm plate a closed fighting compartment SU-12 was not produced in January or February. According to an order of the Main Artillery Directorate, factory #38 was supposed to produce only SPGs with roofs starting with March 1st. Judging by photos of March production vehicles, this order was carried out. At least 215 SU-12s, over a third of overall production, were built without roofs.

Some authors write that roofs were removed due to ventilation issues, but that is not the case. In addition to a roof, March-June production vehicles can be distinguished from earlier ones by the headlight, which migrated to the front of the casemate. All photos of the SU-12 without a roof show this headlight on the left fender. This is a mark of early production vehicles.

The externally visible parts of the SU-12, which was called SU-76 by that point, were finalized by April. Some internal components were later changed, but that did not affect its look.

One of the solutions to the cramped fighting compartment was the ZIS-8 gun mount. It was designed by the design department of factory #92 under the direction of engineer Abramov. The more compact gun mount got rid of the trails inside the fighting compartment. This improved crew conditions, reduced mass, saved on parts, and allowed the SPG to carry 14 more 76 mm shells. The ZIS-8 system was installed in SU-12 #L33432 in May of 1943. Trials showed good results, and factory #92 recommended that the mount be installed in production.

However, the star of the SU-12 was beginning to set. Factory #38's design bureau was working on the SU-15 and SU-16 SPGs which had a more compact gun mount without any changes. The ZIS-8 remained as a prototype.

Fatal error

Production of the SU-12 began without much difficulty, but hit a number of issues in January of 1943. Instead of 150 vehicles that were expected, only 40 were delivered. Other quotas that year were also not met: 150 vehicles were delivered in February instead of 200, same in March. In April, factory #38 met the reduced quota of 100 vehicles. The factory was penalized financially due to their failure. However, production of other SPGs experiences similar problems.

A common issue with many Soviet wartime production vehicles was the quality of assembly. The first 26 SU-12s were sent to the Moscow SPG Training Center on January 5th, 1943. On January 20th, a memo regarding the quality of the SU-12 and SU-35 (SU-122) was written there. Out of the 26 SU-12s that were received 14 of them were functional, 9 were being repaired, and 3 were sent to factory #40 in Mytishi.

Widespread gearbox failures were not yet observed, but there were plenty of other issues. Repair brigades managed to deal with engine overcooling problems due to an absence of a regulator in the cooling system. A big issue was that the right engine started up first, but the electric generator was attached to the left engine. This led to the batteries being discharged. A number of complaints about the welding on the carriers of internal components were made. Finally, there were issues with the crews not knowing their vehicles, which also led to breakdowns.

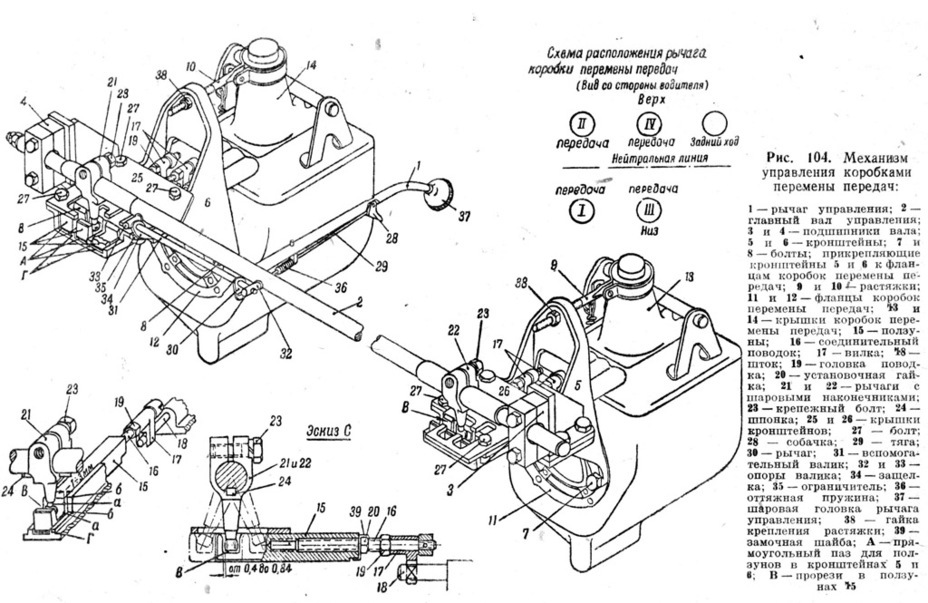

A technical meeting at factory #38 was held on January 28th, 1943, with Schukin, Ginzburg, and the chief designer at GAZ, A.A. Lipgart, in attendance. Quality of assembly was once again blamed for the gearbox defects, both with the gearbox itself and the vehicle overall. There were already some doubts about that being the root cause of the issue. Another point of proof was that a new gear change mechanism was implemented. The system with two gearboxes that were switched with one lever was unreliable. Nevertheless, Ginzburg still denied that the main source of the issue was the system he designed.

On February 12th, Lipgart sent a letter to the People's Commissariat of Medium Machinebuilding, where he outlined his opinion about the issue. According to him, the issue wasn't with the gearbox. In his mind, the main issue was that the gearboxes were not meant to be used with a parallel engine design. GAZ MM trucks that were being produced at the GAZ factory at that time did not have a single gearbox breakdown like the ones seen on the SU-12.

The first SU-12 went into battle in February of 1943. These vehicles were used by self propelled artillery regiments (SAP) formed according to TO&E #08/191. According to it, the 4th and 5th batteries of the SAP were equipped with SU-12s (4 vehicles per battery) and 3 more batteries were armed with SU-35s (the battery commander's vehicle was also a SU-35).

According to a report by the 1434th SAP, three of its SU-12s suffered from breakdowns of gearbox gears. The overall design of the transmission was also criticized. However, the SU-12 proved itself a valuable combat unit. According to documents, the SU-12s of the 1435th SAP fought better, but this is, perhaps, a matter of comparison with the SG-122, which broke down even more frequently.

The concept of a light assault gun was clearly successful. However, clouds started to gather over the vehicle and Ginzburg by March of 1943.

The biggest issues with gearboxes started happening in February-March of 1943, when true mass production of the SU-12 began. Only 35 vehicles left factory #38 in January, but 94 in February and 96 in March. Alarm bells started ringing in late February of 1943. According to a report dated February 25th, 79 vehicles were out of action due to gearbox defects, or 45% of all SU-12s produced by that point. 38 broke during factory trials, 19 in service, and 4 (of the 5 participating) during trials at the Moscow artillery center. This is before a roof added extra mass to the existing 11 tons.

The situation was catastrophic. However, action was taken in Kirov. An investigation performed by the factory #38 design bureau (without Ginzburg's participation) in March of 1943 allowed the issue to be partially mitigated. Schukin's suggestions consisted of reinforcement of the bottom plate, installation of a flexible clutch, and adding rubber shock absorbers to the engines. Nevertheless, factory management was directly indicating that the parallel engine layout was to blame. The design bureau could not guarantee a complete solution to all problems.

According to Schukin, the only real solution was to radically alter the engine-transmission group, more specifically, use a layout like the one on the T-70. Management agreed, and the development of the SU-38, SU-15, and SU-16 was launched. Changes to production vehicles were made in parallel, which were aimed at solving the issue with gearboxes. In addition to a reinforced bottom plate, rubber shock absorbers, and a flexible clutch instead of a rigid one, other changes were made. The gear changing lever system was replaced with a mechanical linkage. The final drive friction clutches were weakened by 25%.

The rate of breakdowns decreased somewhat thanks to changes made by factory #38, but it still remained high. The issues were so common that Stalin personally decreed that the SU-12 be removed from SPG regiments. GKO decree #3184 signed on April 14th, 1943, created special brigades out of factory #38 staff that travelled between units equipped with early production SU-12s and modernized them. Additional friction clutches were introduced as a part of reliability improvements. A number of authors refer to SU-12s modernized in this way as SU-12M, but this index or the index SU-76M was not used in regard to these vehicles.

All of these measures were not enough. Gearboxes continued to break en masse. The GKO ran out of patience. Stalin signed a GKO decree to cancel production of the SU-76 (that is what the SU-12 was called after May) as soon as the hulls produced up to June 1st were used up. Thunder struck on June 7th, when a harsher decree (GKO #3530 ''On SU-76 SPGs'') was issued.

''SU-76 SPGs suggested by the People's Commissar of Tank Production (comrade Zaltsmann) and GAU KA chief (comrade Yakovlev) and accepted into production by GKO decree signed on December 2nd 1942 have had mass issues of gearbox breakdowns and other defects.

These issues were caused by a reckless approach of the People's Commissar of Tank Production, comrade Zaltsmann, GAU chief comrade Yakovlev, director of factory #38 comrade Yakovlev, and designer comrade Ginzburg to the design of the SPG and its trials.

Measures taken to correct the gearbox defects and other defects suggested by the People's Commissar of Tank Production (comrade Zaltsmann) and GAU KA chief (comrade Yakovlev) carried out by factory #38 according to GOKO decree #3184 issued on April 14th, 1943, did not correct the defects and did not ensure reliable performance of the SPG.

The State Committee of Defense decrees that:

Production of the SU-76 at factory #38 will cease immediately.

<…>

For the irresponsible proposal of mass production of the SU-76 and improvements made to it, the People's Commissar of Tank Production, comrade Zaltsmann, will receive a reprimand. Comrade Zaltsmann is warned that further omissions regarding the quality of armoured fighting vehicles will result in strict punishment.

The designer of the SU-76 SPG, comrade Ginzburg, is to be removed from his post at the People's Commissariat of Tank Production, forbidden from further design work, and sent to the NKO to be assigned to the Active Army.

GAU chief Yakovelev is instructed to increase his diligence and control regarding all experimental works on armoured fighting vehicles, paying special attention to correct selection of trials commissions.

The People's Commissariat of Tank Production (comrade Zaltsmann) and GAU KA chief (comrade Yakovlev) are to find and punish the guilty workers of the NKTP and GAU KA that irresponsibly approached the trials of the SU-76 SPG.''

Ginzburg was sent to the 32nd Tank Brigade, where he was assigned the post of deputy commander of technical matters. His combat career was not long. He died on August 3rd, 1943, near the Malaya Tomalovka village of Kursk oblast. This incident did not go unnoticed by Zaltsmann either. He was removed from the post of People's Commissar of Tank Production on June 28th. The staff at factory #38 were not punished, as they were not involved in the development of the defective component, which became the Achilles' heel of the SU-12. Schukin's team quickly designed the replacement SU-15M. This vehicle, more commonly known as SU-76M, entered into production in July of 1943. As for the SU-12, only 609 units were produced (608 production and a prototype).

Despite the design defects, the SU-76 was not barred from the front lines. As mentioned above, factory #38 managed to partially mitigate the reliability issues. Formation of SAPs according to TO&E #010/456 began in April of 1943. According to this decree, a regiment contained 21 SU-12s. However, due to technical issues, these units saw limited use in the summer of 1943. However, the SU-12 saw plenty of action in units formed according to TO&E #08/191 and other units. The 45th and 193rd regiments fought at the Battle of Kursk, which had a total of 11 SU-12s. 5 more SU-12s were a part of the 1440th SAP. Poor ventilation of the fighting compartment was recorded during the summer battles, earning the vehicle the nickname «gas chamber».

As the SU-15M began entering service in the fall of 1943, the SU-12 was forced out. Nevertheless, these vehicles were still around in the summer of 1944. They were not recorded separately from the SU-76M (SU-15M) and SU-76I. As a result, it is hard to keep track of Ginzburg's progeny.

No SU-12s survive to this day. However, one SU-11 remained at the NIBT proving grounds at Kubinka, which later turned up at the museum. It is still labelled ZSU-3» there, even though it differs substantially from the vehicle with that name. Two transmission access hatches and two starter hatches suggest the parallel layout of engines, a layout that was the death of one of the leading Soviet engineer-designers.

Translated by Peter Samsonov. Read more interesting tank articles on his blog Tank Archives.

Sources:

- Central Archives of the Russian Ministry of Defence;

- Russian State Archive of Economics;

- Russian State Archive of Socio-Political History;

- Russian State Archive of Film and Photo Documents.