December of 1942 was a key month in the history of Soviet SPGs. Work on light and medium SPGs reached the stage of preparation for production. The Ural Factory of Heavy Machinebuilding (UZTM) was chosen to produce medium SPGs. There were two reasons for this. In addition to the fact that development of the U-35 SPG was coming to an end in Sverdlovsk, there was a strong manufacturing base here. Local production of T-34s, which started here in late September of 1942, ensured a supply of chassis for SPGs.

Taking into account the factory's abilities, GKO decree #2559 ''On organization of production of SPGs at the Uralmash factory and factory #38'' was signed on December 2nd, even before the start of U-35 trials. According to this document, UZTM was expected to deliver the first two SU-35 SPGs (later renamed SU-122) in December of 1942.

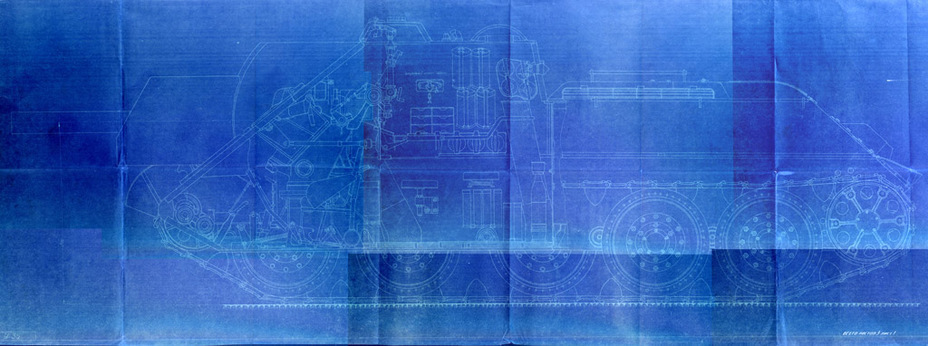

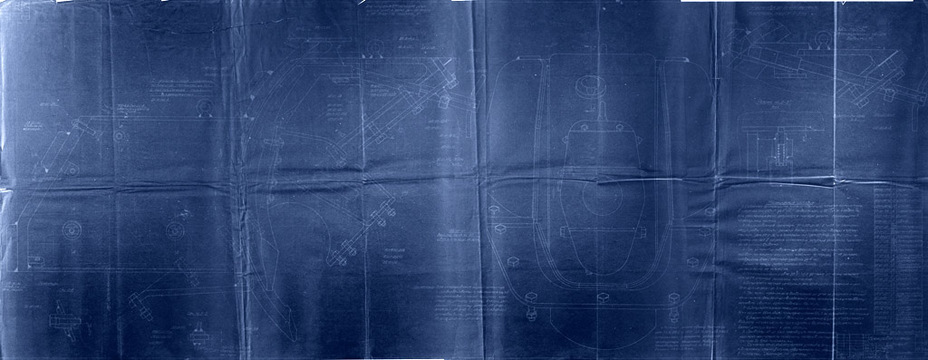

U-35, annotated edition

Thanks to somewhat erroneous letter and a post-war summary of work at UZTM, the real history of the U-35's path to production remained buried in archives. The actual history of this SPG is different from what most historians write.

Yes, the U-35 passed mobility trials. Technically, it also passed gunnery trials. After that, there are some complications. The commission noted that UZTM's design has a poorly laid out fighting compartment, one that was even dangerous for the crew. It was too cramped and uncomfortable. The fighting compartment of the SG-2, designed by factory #592, was superior. Of course, it had its drawbacks, but there were fewer of them. The SPG developed in Mytishi passed this part of the trials, but the T-34 chassis it was built on was defective. As a result, the vehicle failed mobility trials. The commission made the following conclusions.

''The commission considers it necessary to task the Uralmash factory to improve the 122 mm SPH, taking into account the fighting compartment layout of the 122 mm SPH designed by factory #592, and correcting the drawbacks noted in this report. The improved prototype of the SPH should be subjected to trials at the factory for the final decision on accepting it for service in the Red Army.''

This solution was correct, given the situation. UZTM already received the order for U-35s, it was too late for a competition. Second, factory #592 was included in the NKTP by decree #2559, and was reformed into factory #40, which would built T-70 light tanks. Even without these decisions, factory #592 had no supply of T-34 chassis, whereas there was no such issue in Sverdlovsk.

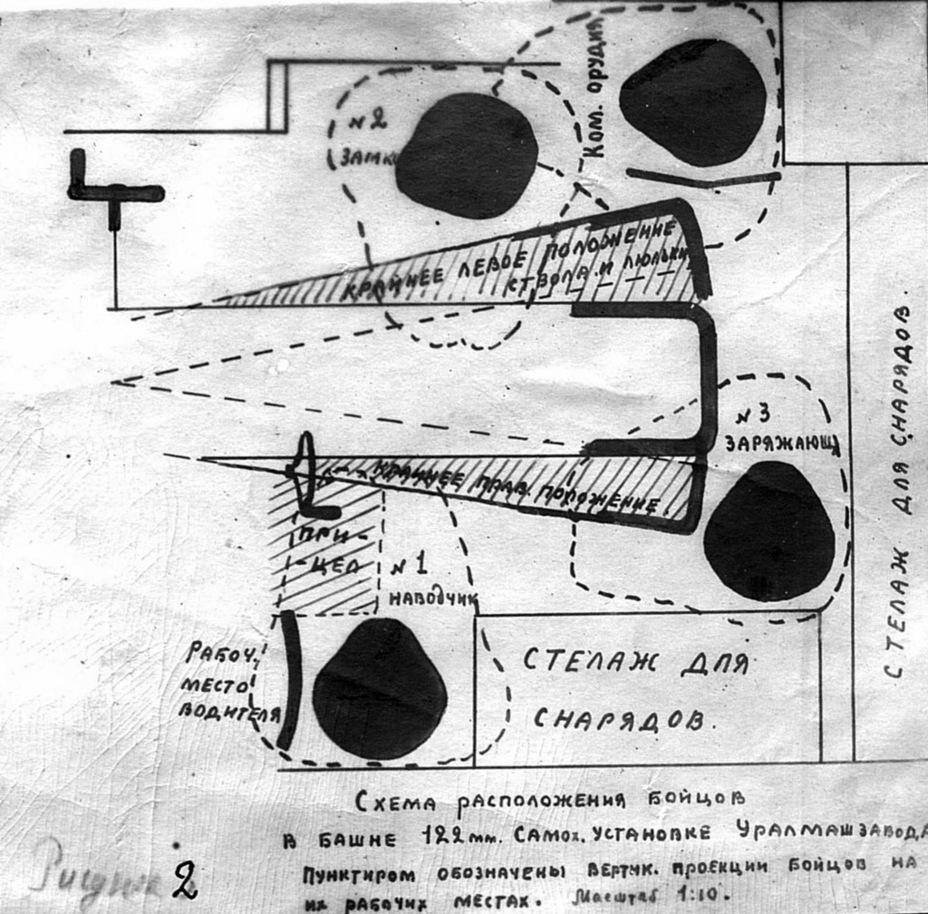

Improvements of the U-35 began even before comparative trials finished. Since Gorlitskiy was at the trials, N.V. Kurin headed the design group. The reworked U-35 project was ready by mid-December. It was reviewed at a technical meeting on December 15th at UZTM. Aside from Kurin, Zh.Ya. Kotin, chief designer at factory #9 F.F. Petrov, his deputy A.N. Bulashev, the chief designers of UZTM N.D. Verner, and military representatives, including G.Z. Zucher, were present.

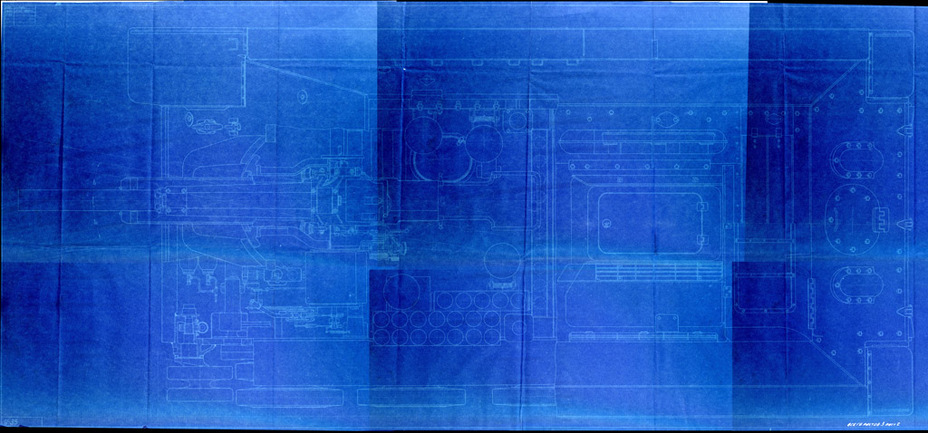

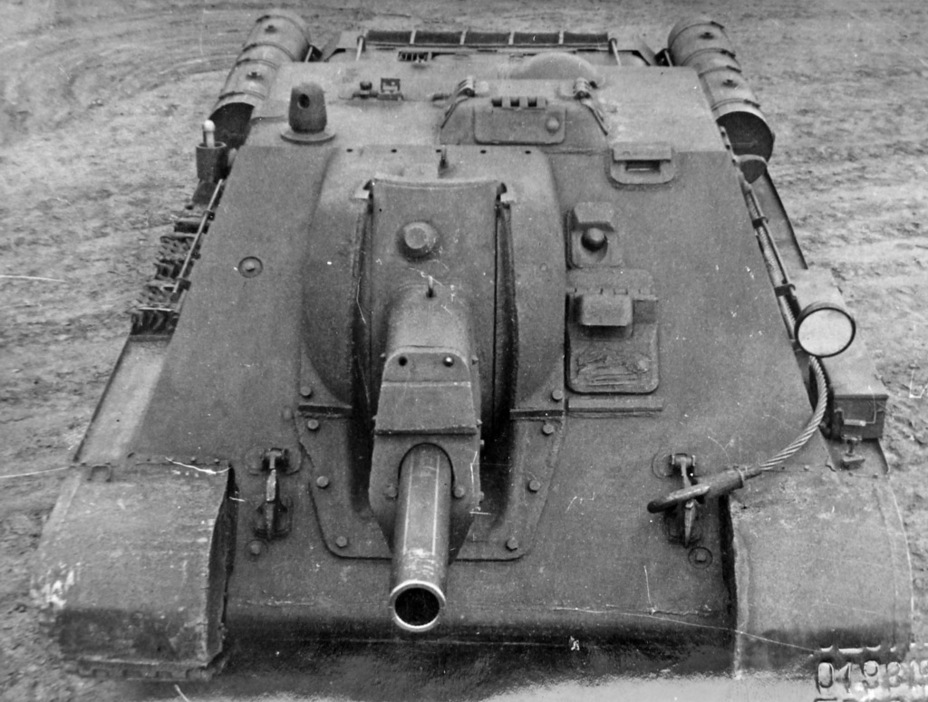

14 changes were made to the design of the SPG. Many of them were taken from the SG-2. The biggest similarity to factory #592's SPG was a dome for a periscopic sight with three openings. The hatch in the roof was also similar, but the UZTM design was one piece. As on the SG-2, the commander received a PTK periscope instead of a commander's cupola. The ammunition rack location was also similar.

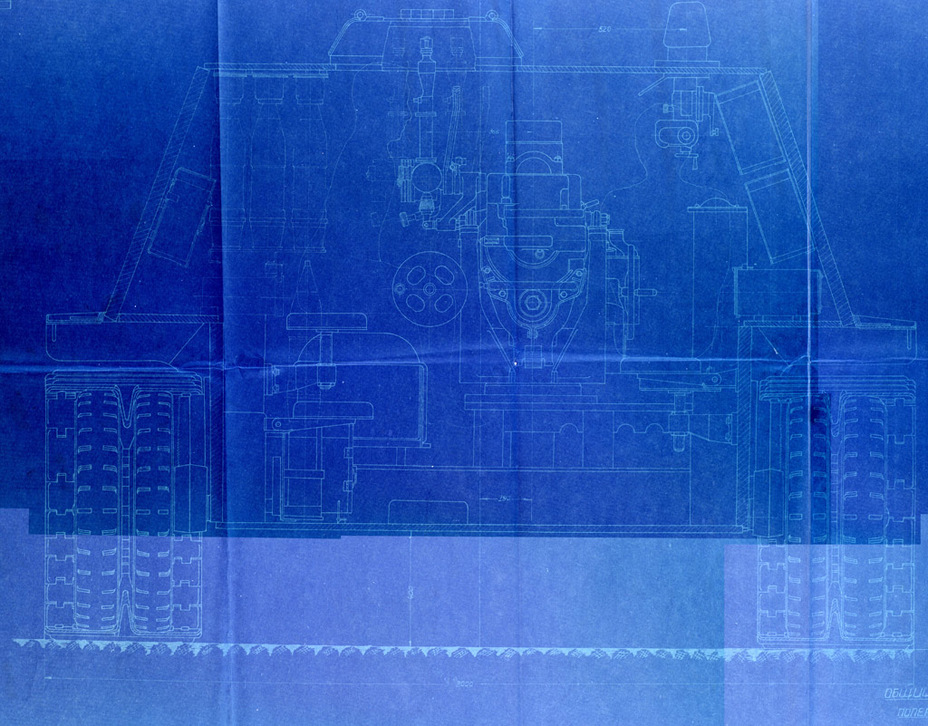

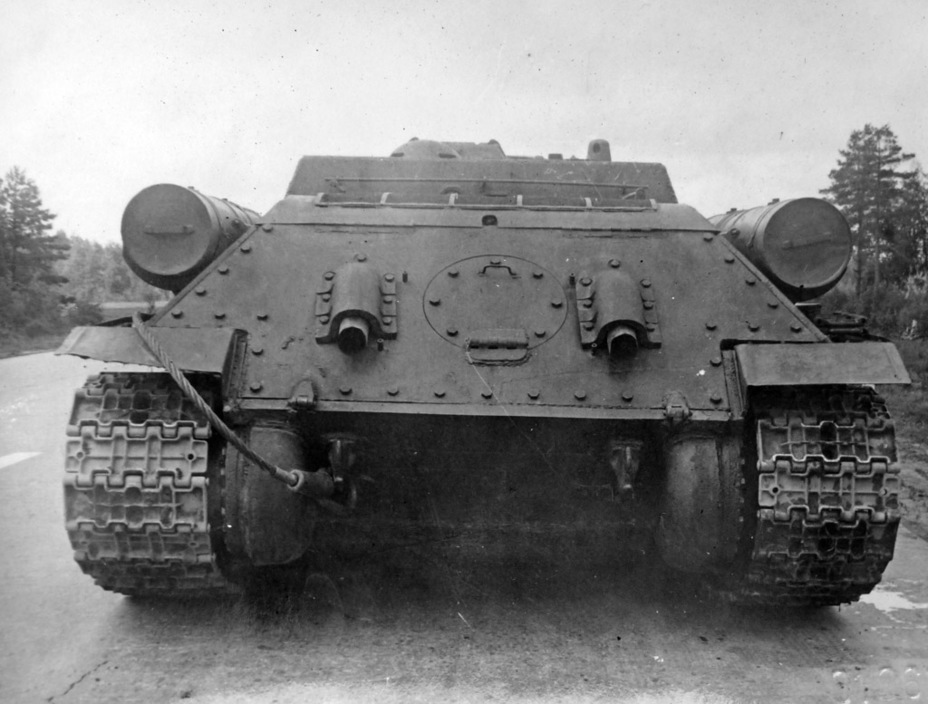

Despite a number of borrowed elements, the new U-35 had many differences from both the SG-2 and its initial form. The designers discarded the idea of using the T-34 chassis with as few changes as possible. The upper front plate became simpler, without a «step». Other plates of the casemate were also altered. The gun mount changed, the tray disappeared, and the mantlet was changed to avoid openings.

The commander's seat moved forward. He also operated the radio and aimed the gun in the vertical plane. There were folding seats for the loaders. The gunner's seat changed. The upper left fuel tank was removed in order to increase the volume of the fighting compartment. Periscopic observation devices were installed instead of vision slits. Additional external cylindrical fuel tanks, made in the style of Kirov factory tanks, were also added.

The reworked U-35 blueprints were approved after review. Provisional technical requirements for a pilot batch were also approved. The use of the ''Luch'' (ray) device to illuminate the sights at night was established. The meeting participants also accepted factory #9's proposals to change the gun mount. In part, this meant removal of lubrication openings and the grease dispenser in the upper elevation mechanism gearbox. The cradle, upper mount, sight mount, elevation and turning mechanisms, and the balancing mechanism of the M-30 were changed.

The minor corrections had little effect on the overall design. After 2.5 years of work on an SPG on the T-34 chassis, it was finally headed for production. During this time, its concept changed completely.

Sverdlovsk tried to hide the fact that the final version of the U-35 was the result of a combination of effort from two design bureaus. However, a letter written on March 13th, 1943, by the Deputy Chief of the Main Artillery Directorate (GAU), Lieutenant-General of Artillery I.I. Volkotrubenko reveals the truth. The letter concerned the award of the Stalin Prize to Gorlitskiy and Kurin for the creation of the SU-35. Volkrotrubenko noted that the SPG was also the result of work by Sinilshikov and Perervushin, the creators of the SG-122 and SG-2. The deputy chief didn't forget that a number of solutions from those vehicles were used in the SU-35. As a result, all four designers received the Stalin Prize Second Class.

Production priority

The approval of blueprints and provisional requirements were a sign to begin preparations for mass production of the SU-35. UZTM rushed to work. The factory had only two weeks to begin production, but nobody reduced the requirement for T-34s. According to the plans, 100 T-34s were expected from Sverdlovsk in December of 1942. That goal was met (50 of the tanks were equipped with radios).

Due to the close deadline, there was no time to build a prototype. The NKTP took a risk and began production without a trial stage. The characteristics of the vehicle would be obtained from a pilot SPG.

Changes were made to the blueprints while the first SPGs were being built. That was caused by the fact that there was no prototype, which is usually the testing ground for technical documentation. The first SPGs were somewhat different from their blueprints. These changes meant that parts sometimes had to be trimmed to fit during the assembly process.

The factory did not conceal these issues. They were openly discussed at meetings, which took place in late December. One of these meetings, held between Kotin, Gorlitskiy, UZTM management, and GABTU and GAU representatives took place on December 27th. By then, the pilot batch was nearly finished, but the deadline was around the corner. As a result, a decision was made at the meeting to accept the vehicles without ammunition racks, since their blueprints were not yet ready. One vehicle was fully equipped, to meet the tactical-technical requirements. A number of decisions regarding the requirements for the pilot batch were made.

A meeting on December 31st solved issues in a similar way. It turned out that the pilot vehicles differed from the blueprints in several characteristics. For instance, according to the requirements, the vertical arc had to range from −3 to +25 degrees. In reality, this value was only from −1.3 to 23.3 degrees. Instead of 8 kg of effort, the aiming mechanism required up to 14 kg to operate. It was decided to accept the SPGs even with these deviations. Another issue was that the gap between the gun mantlet and shield were more than allowed. This was solved by adding additional 10 mm thick plates.

Trials of the fifth pilot SU-35 began on December 28th. 40 shots with a reinforced round were fired, after which the SPG was driven for 50 km. No deformations or breakdowns were observed after the trials. There were also no complaints about the vehicle's function. The issue of crew comfort was reviewed. It turned out that the conditions of the crew were much better than on the U-35 prototype.

Through heroic efforts, UZTM met the quota for 25 vehicles. On January 3rd, 1943, the SPGs were loaded on a train and sent to Moscow. An agreement for 300 SU-35s at a cost of 200,000 roubles each was already signed with the factory, at a rate of 100 SPGs per month. It turned out that the plan for January was impossible to fulfil. The situation was made worse by time spent idling due to a lack of fuel and electricity. This impacted the production of the T-34 as well as the SU-35. The factory had not delivered a single T-34 by January 13th, and only 5 tanks were delivered by the 22nd (4 of them with radios). In total, only 50 T-34s were produced in January (25 with radios).

The situation with the SU-35 was even more difficult. A number of changes were made to the requirements and blueprints after the pilot batch. This kind of artisanal approach to assembly wouldn't fly for mass production, and there were no spares left over from December. As a result, only 32 SPGs were built out of 100 in January. As of January 30th, not a single one was delivered to the customer. This was caused by the fact that the factory was hurriedly working on T-34s. These SU-35s were finished off in February. As for the February order, it was only started on the 10th.

The issues that the factory experienced while producing two vehicles at the same time forced the NKTP to shift their priorities. Since five factories were producing the T-34 at the time, and UZTM output was never that high, the SU-35 was given priority. For this reason, only SU-35s were built in Sverdlovsk. from February 10th to February 20th. The first 6 T-34s were only built on the 21st. As a result, the factory managed to deliver 100 SU-35s, but only 9 T-34s, since the factory received no turrets. The tanks were finished up in March. 39 were ready by the 5th, 20 of them with radios. The situation repeated itself in March. Most of the month was spent focused on SU-35 production. As a result, the quota for 100 SU-35s was met once more.

Issues with the SU-35 cropped up not only during production. Complaints that the fighting compartment was too cramped began arriving in January. The same complaints were made in February, when January production vehicles arrived in Moscow.

In addition, there were many complaints about the travel lock. It bent out of shape during marches quite often. The cause was that the components were sent to the assembly plant without thermal treatment. The defective locks were replaced, and the results were satisfactory. However, the defect returned on February production vehicles. This time, the whole assembly was found to be defective. A technical meeting resulted in a decision to test 10 vehicles, 5 of which had travel locks, and 5 did not. The locks broke, but the system remained functional. UZTM designed an additional clamp as a temporary measure, but it was clear that a more radical solution was needed. A contest to design a new travel lock was held in February at UZTM, with three designs presented. The conical lock affixed to the upper part of the gun mantlet was deemed the best. The new lock was implemented in mid-March.

An opening was made in the upper part of the mantlet, which was covered with a round cover. Extra plates were also welded on the front of the mantlet. Some historians assumed that this was additional armour, but that was not the case. These plates functioned as counterweights. This is why there could be one, two, or none at all.

The new travel lock and a new mantlet were introduced into production starting with late March of 1943. They were the first major changes to the SU-35. Another serious change happened on April 3rd. The SU-35 became the SU-122. Aside from a new name, the April vehicles received a new sight dome. Several months of use proved that there also needs to be a rear observation port. Starting in April, the domes were produced with four ports.

Work on a modernized SU-122 began in January of 1943. The vehicle, known as SU-122M, deserves a separate article. Here, let us only mention that UZTM's design bureau resolved the issue of a cramped fighting compartment and widened the casemate. Gorlitskiy resisted a proposal to introduce the same changes on the production model, arguing that it would increase the mass by 600 kg.

April was a big month for UZTM. A whole load of problems rained down on the factory. Widespread tire defects were discovered both on SU-122s and T-34s. There were also cracks spotted in armour.

UZTM wrote to the GAU Artillery Committee, asking to replace the 20 mm thick roof with a 30 mm plate. The issue was that the roof was overloaded with welding seams, which often resulted in cracks that had to be covered up by additional plates. The proposal was approved, since it only increased the mass of the vehicle by 100 kg. The GABTU reacted in a different way, rejecting the proposal, since using a thicker plate of softer armour was unacceptable. The rejection was only made in early June, so a number of SU-122s with thicker roofs were built after all.

The number of issues in April meant that only 75 SPGs were delivered instead of 100. Additional changes were made in May of 1943. By GAU's demand, an access hatch to the track tension mechanism was added in the lower front plate. The handrail in the rear of the casemate was removed. It was deemed inconvenient to use. Towards the end of May, an enlarged cupola for the panoramic sight was introduced. These changes were the last major alterations of the SU-122 design. Some historians introduced a taxonomy of series with these minor design differences, but there were no series in reality for the SU-122 or any subsequent SPG.

May was a calmer month, and the 100 vehicle target was met. There was no escaping factory defects, however. On May 19th, it was discovered that the return mechanism cylinder was drilled through on one of the M-30s. Zucher ordered that all SPGs on hand must be checked. A similar defect was found on two more SPGs, and 100 SPGs had dirt underneath the mantlet. The defects were corrected after this investigation. There were also difficulties with supplies of road wheel rims and gearboxes.

June of 1943 was also a calm month. The 100 vehicle quota was met. July was a more difficult month, due to the weather, rather than defects. Torrential rains turned the roads into impassable swamps. A road to the Medniy Rudnik settlement (modern day Verkhnyaya Pyshma) was used for testing tanks and SPGs. Due to the strategic importance of the road, the Sverdlovsk regional committee prohibited the use of the road. As a result, acceptance testing stood still for two weeks. There were also issues with track links, gearboxes, and armament. As a result, only 78 T-34s and 72 SU-122s (later corrected to 76) were delivered.

August of 1943 was the last month of SU-122 production. The Battle of Kursk showed that it was necessary to have the SU-85 in production. T-34 production ceased in Sverdlovsk as well. UZTM was expected to deliver 25 SU-122s in August, but 32 vehicles were shipped. In total, 640 SU-122s were built in Sverdlovsk from December 1942 to August 1943.

Jack of all trades

The issue of how to use the SU-122 was resolved even before the pilot batch was completed at UZTM. GKO decree #2662ss «On the formation of Supreme Command Reserve SPG regiments» was published on December 27th, 1942. According to the decree, 30 self propelled artillery regiments (SAP) would be created, following TO&E #08/158. The regiments contained 16 SU-12 (SU-76) and 8 SU-122.

The 1433rd and 1434th SAP were the first to receive SU-122s. Both regiments were formed according to TO&E #08/191, which allowed for mixed equipment. The commander's vehicle, as well as three batteries of 4 SPGs each, were SU-122s. Two more batteries were equipped with SU-12s (SU-76). Initially, the 1435th SAP was organized with the same structure, but it received SG-122s instead. The same structure (15 SU-122 and 8 SU-12) was used in SAPs 1436-1444 and 1446-1451.

According to reports, the 1433rd and 1434th SPG regiments that arrived at the Volkhov Front were used to support tanks and infantry. The SPG crews waited for the artillery barrage to cease, and opened fire at surviving enemy strongholds. It turned out that 5-8 shells are needed to take out a machinegun nest, and 10-12 to take out a bunker. 3 ammo loads were consumed over a day of fighting. The most effective range of fire was from 300-400 meters.

Reports indicated that the crew was at risk in battle. There was a chance of injury at wide traverse angles. Overall, the fighting compartment was cramped, and the crew's working conditions were uncomfortable. Another problem with the gun traverse was that the sight ended up looking into the wall of its dome at extreme angles.

The driver's «half-hatch» only worked to improve his vision. Demands to make it bigger came in from its users, but it was impossible, since the gun was too large. The small hatches meant that drivers could die if they didn't have enough time to leave a burning vehicle.

Experience also revealed the drawbacks of a mixed SAP structure. The result was TO&E #010/453. It authorized a regiment of 16 SU-122s (4 batteries of 4 vehicles) and a commander's T-34. This was the structure of the regiments at the Battle of Kursk. Here, the enemy first used Tiger tanks in large numbers, as well as Panthers and Ferdinands. The SU-122 had many close encounters with this «menagerie». In part, vehicles from the 1454th SAP fought in the north, defending Ponyri. Despite some success against German tanks, it was clear that the 122 mm gun was not the best anti-tank weapon. This is not surprising, as the SU-122 was created as an assault gun.

There were two solutions to this issue. The first was the introduction of SU-85 SPGs, armed with 85 mm D-5S guns. The second was the introduction of the BP-460A HEAT round. Each SU-122 was authorized to carry 10 of these shells. The appearance of new German tanks did not mean that the SU-122 would vanish from SAPs. These vehicles proved themselves to be effective in a support role. Some SPGs survived several crews. The SU-122 was still used in battle in 1945.

Overall, the SU-122 turned out to be a successful fighting machine. Despite a number of drawbacks, it proved itself a valuable infantry and tank support asset. However, very few of these SPGs survived the flames of war. Today, four surviving vehicles are known. Only one is complete. This is SPG #305320 from the 1418th SAP of the 15th Tank Corps of the 3rd Guards Tank Army. The SPG from the 4th battery was commander by Lieutenant V.S. Prinorov, and fought in offensive battles of July of 1943. On July 24th, during battle for Nikolskoye, the vehicle was knocked out. The breech operator and gunner were killed, the commander and driver were wounded. The vehicle was sent back for repairs, and its further fate is unknown. During use, the road wheels were replaced by newer ones, without perforations. The vehicle can be seen in Patriot Park.

Translated by Peter Samsonov. Read more interesting tank articles on his blog Tank Archives.

Sources:

- Central Archives of the Russian Ministry of Defence;

- Russian State Archive of Socio-Political History;

- Russian State Archive of Economics;

- Russian State Archive of Film and Photo Documents;

- Author's photo archive.