The American army had the largest fleet of heavy tanks in the world at the start of the 1930s. Unfortunately, these were obsolete Mark VIII tanks, also known as Liberty. They were built to British specifications using experience learned from the First World War, but these tanks came too late to fight. No heavy tanks were built in the US after the war was over. Work on this topic only resumed after the start of WWII. The result was the Heavy Tank M6, the first truly domestic heavy tank design.

Blank slate

The lack of a heavy tank in the American army had a simple cause. The army had no need of such a vehicle. This can be clearly seen by tracing the evolution of American tanks in the interbellum period. The country's large territory necessitated the creation of quick fighting machines that could cover large ground quickly. A heavy tank is ill-suited for such a task. The main task of heavy tanks is to break through prepared and well defended fortifications, which were entirely absent from the North American theater of war. It's not surprising that no work was done on heavy tanks until the late 1930s, barring individual proposals, which were rejected in early stages.

The situation started changing with the start of WWII. The American army brass understood that the US will be drawn into the war, sooner or later. The European theater of war was very different from North America, and it meant that a breakthrough tank was now necessary. The British and French hurriedly designed new types of heavy tanks. The Americans joined them on September 27th, 1939. However, the Aberdeen Proving Grounds staff were phoning it in for the first six months.

The situation began to change in May of 1940, when the front in Western Europe erupted with activity. On May 20th, 1940, General Lynch, the commander of American infantry, initiated work on a heavy tank. A tank weighing 50-80 short tons (45-73 metic tons) was required. On May 22nd, the Ordnance Committee altered the requirements, deeming that a 50 ton tank would be enough.

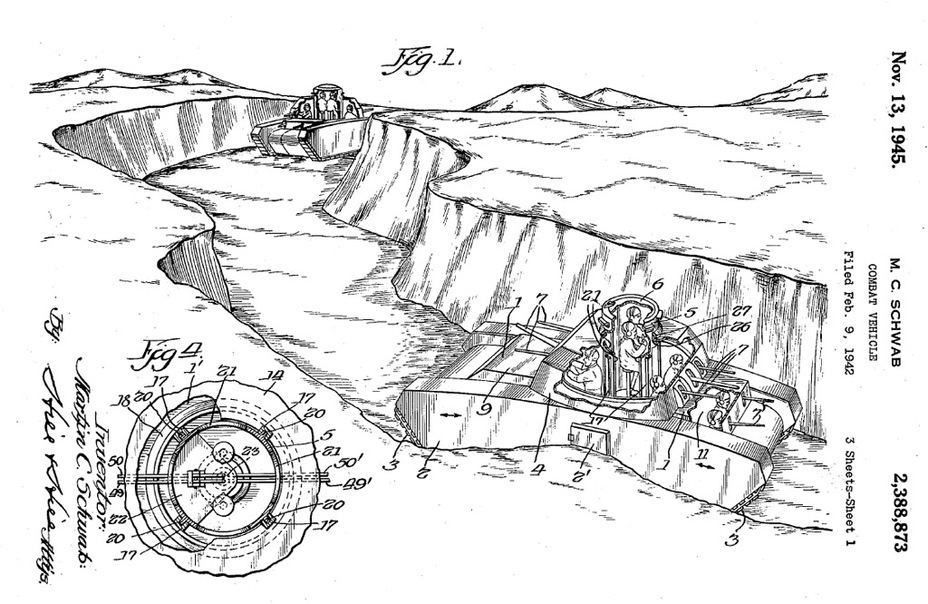

The project seemed quite odd initially. Even though nothing but a textual description remains, it is clear that the Americans did not seek any shortcuts. The tank would have 4 turrets. Two main turrets, armed with 75 mm T7 (M2) cannons, each had 270 degrees of range. Two auxiliary turrets had all-round coverage. One was armed with a 37 mm M5 gun and a Browning M1919 coaxial machinegun, the other had a 20 mm autocannon and a coaxial machinegun. Each turret had powered traverse. In addition to the aforementioned armament, the tank also had 4 machineguns in ball mounts.

Despite significant mass, the tank would be very compact and have high mobility. The length of the tank was 7.5 meters, the width was 3.4 meters, and the height was 2.76 meters. The top speed was rated at 40 kph, at the level of the Medium Tank M2. The thickness of the armour was 76 mm on the front and 64 mm on the sides.

Colonel Barnes, the head of the technical department of artillery at the time, headed the project. On June 4th, he proposed an alternative location of armament. The tank would have one turret with a 75 mm cannon, and two more turrets would have 37 mm cannons and machineguns. Barnes also highlighted the requirement that the tank needed to fit into the dimension restrictions of railroads. On June 17th, Barnes raised the issue that development of a superheavy 80-90 ton tank might be required soon, but it was never mentioned again. General Lynch shared Barnes' scepticism regarding excess turrets. In a letter written on June 20th, 1940, he reasonably stated that every extra turret is extra mass.

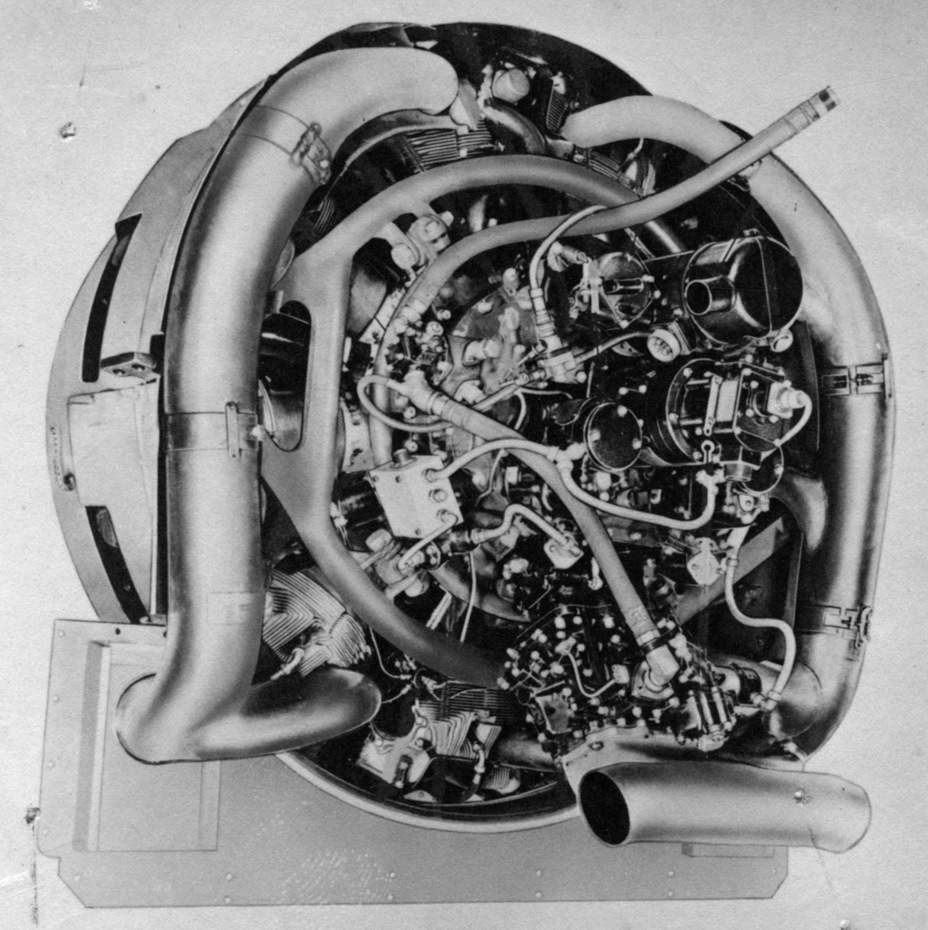

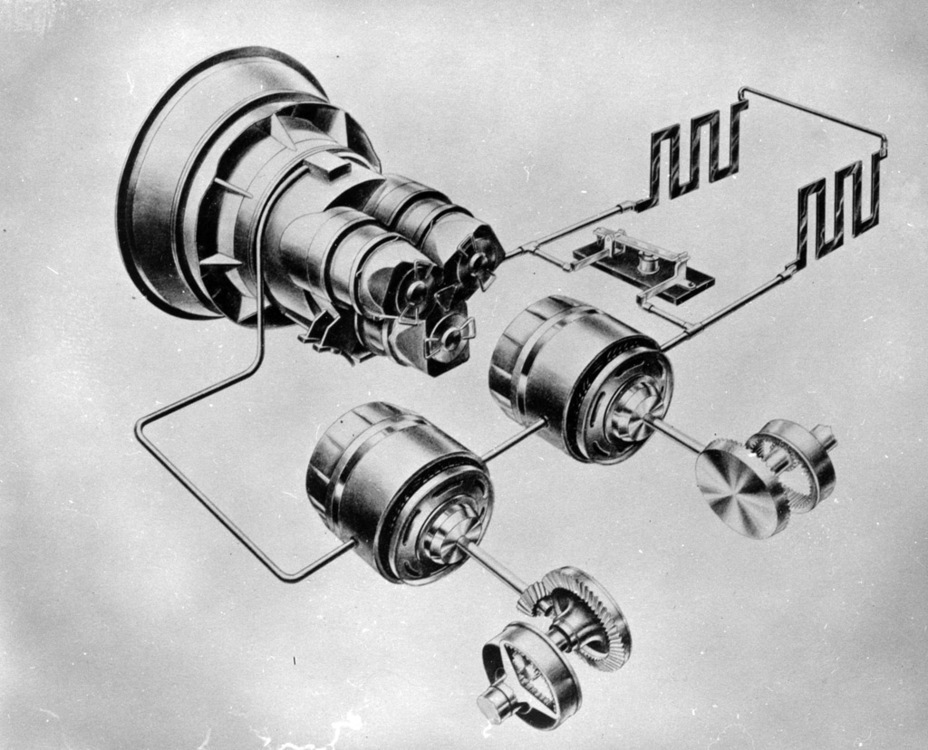

Meanwhile, Barnes was solving more pressing issues. The heavy tank issue had a high priority, and the project had to go from theory to practice. Negotiations with General Electric began on July 11th, 1940. The industrial giant proposed to take on the development work, especially since they had a subsidiary in Erie, Pennsylvania, which produced locomotives and train cars. The military declined this offer, but General Electric still took part in the development. It began to work on an electric transmission. These designs had nothing to do with Ferdinand Porsche and his Typ 100. By 1940, General Electric had dozens of transmissions for various vehicles.

Barnes met with representatives of Marmon-Herrington and Schneider Hydraulic Corporation on July 15th. He offered them a project of a torque converter for medium and heavy tanks. On the same day, he met with representatives of the Baldwin Locomotive Works from Eddiston, Pennsylvania. This company ended up receiving the contract for development and production of a heavy tank.

Development of the American heavy tank was going at full speed starting with the end of July of 1940. Design work at the Aberdeen Proving Grounds continued, and other companies join in gradually. Spicer received the order for a hydraulic gearbox, which would be an alternative for an electric transmission. The question of whether or not a mechanical gearbox should be used was raised. In August, General Motors demonstrated its GM Hydra-Matic automatic gearbox. Work on various variants of the tank continued.

The Americans quickly decided that it was pointless to have a multi-turreted tank with armament equal to that of a medium tank. As a result, the vehicle, indexed Heavy Tank T1 on August 22nd, 1940, slowly changed form. BLW's work was slowed down by the indecision regarding the type of transmission on behalf of their customer.

A meeting was held on September 17th to discuss the developments by General Electric. The cost of development of an electric transmission was estimated at $145,000. A choice between three torque converters, the Schneider, Brog Warner, or General Motors, also had to be made. Another alternative was the Oldsmobile automatic gearbox. A choice had to be made from two gearboxes, one of which cost $125,000 to develop, the other $150,000. A demonstration of the model of the Heavy Tank T1 was scheduled on that same day. It was only partially ready, since the type of transmission still was not decided upon. General Electric did not give up, but the Oldsmobile design slowly gained favour. One of the reasons was that the electric transmission was heavier.

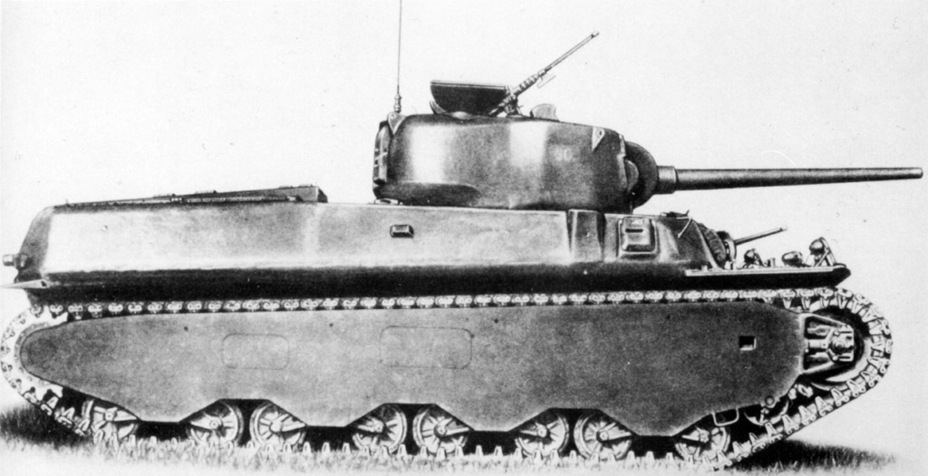

A contract with Oldsmobile for $150,000 to develop the Hydra-Matic gearbox was signed. The choice of gearbox was made, at least for a while. On the same day the Ordnance Committee changed their requirements for the Heavy Tank T1. The mass remained the same, the length was reduced, the crew was set at 6-7 men. The biggest change was the number of turrets. The potential analogue to the Soviet T-35 was gone. Instead, the tank had one turret, which would house the T9 76 mm gun and a coaxial 37 mm M5E1 gun. The T9 was based on the 76 mm AA gun, and so the armament was appropriate for a heavy tank. A vertical stabilizer was proposed.

The rear of the turret housed a Browning M2HB AA machinegun. A Browning M1919 machinegun in the commander's cupola, similar to the one used on the Medium Tank M3, was also supposed to help against aircraft. Four more machineguns (2 Browning M2HB and 2 Browning M1919) were installed in the front of the hull.

As it turned out, it was too early for Oldsmobile to celebrate a victory. Barnes, now a Brigadier General, gave an order to develop a mechanical gearbox on December 23rd, 1940. Its creator was the Timken company from Detroit. The electric transmission was also not yet buried. A decision to install a General Motors electric transmission on the Heavy Tank T1E1 was made on February 13th, 1941.

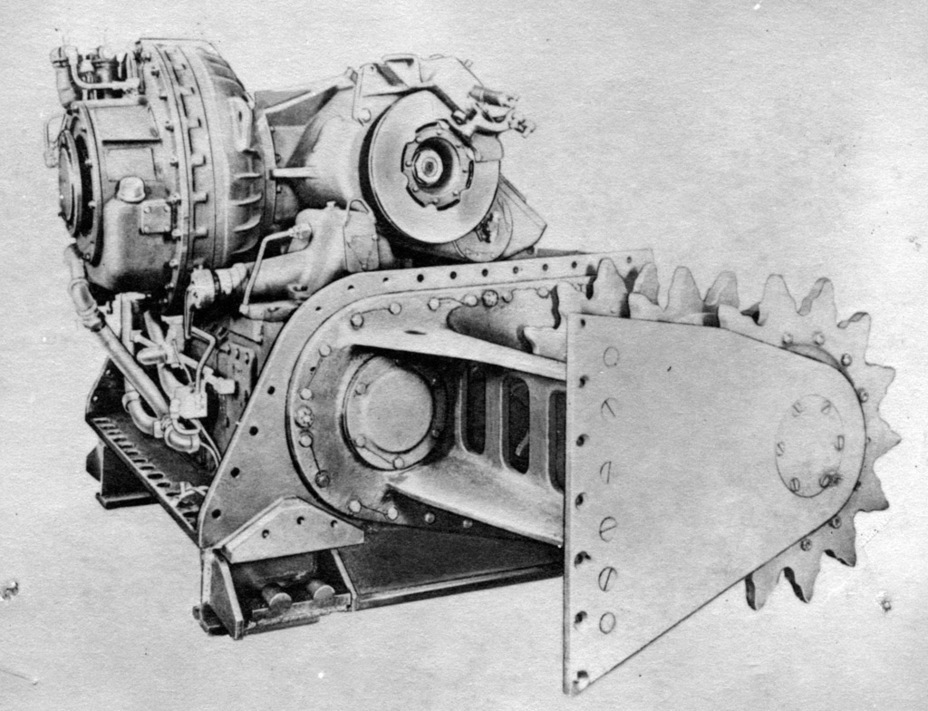

The Heavy Tank T1E2 with a Timken gearbox and T-16001 torque converted was approved on April 15th. All of the above tanks would be equipped with a Wright G-200 Model 781C9GC1 engine, which had a maximum power of 960 hp.

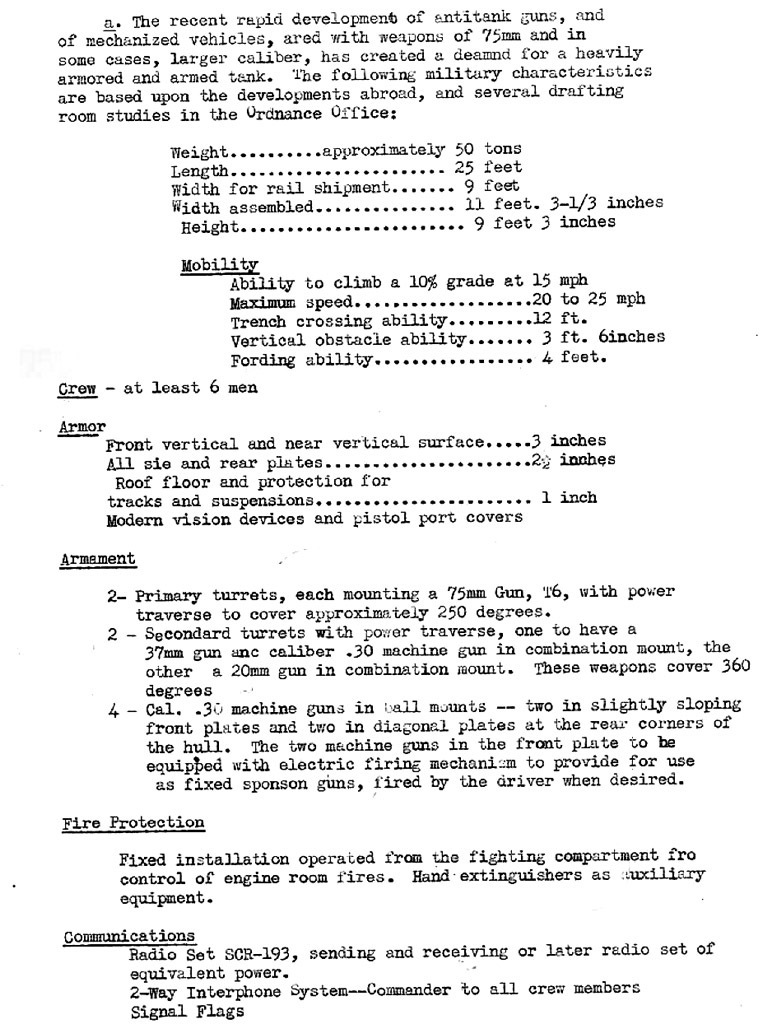

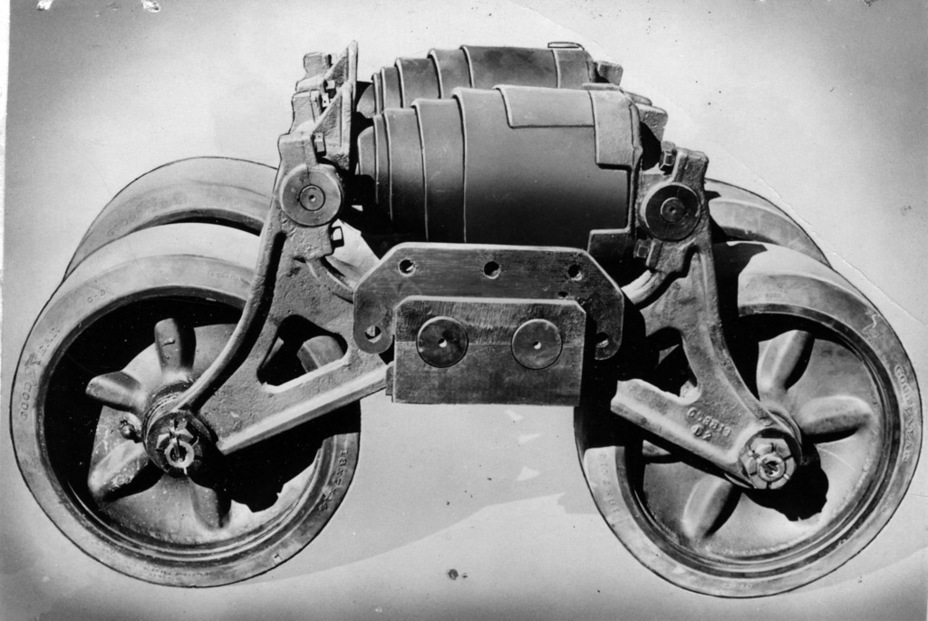

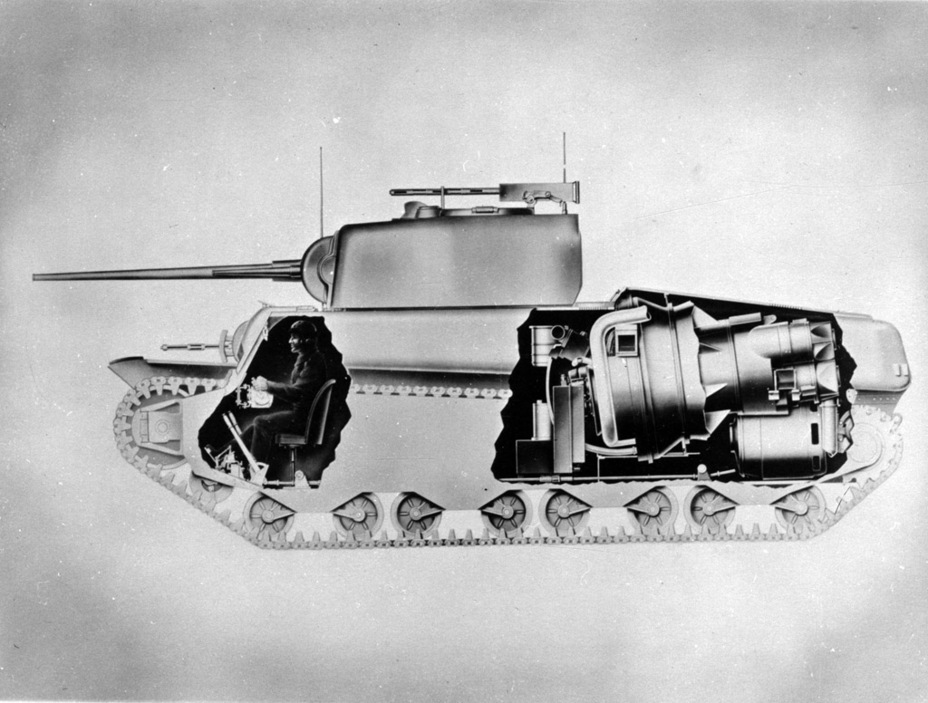

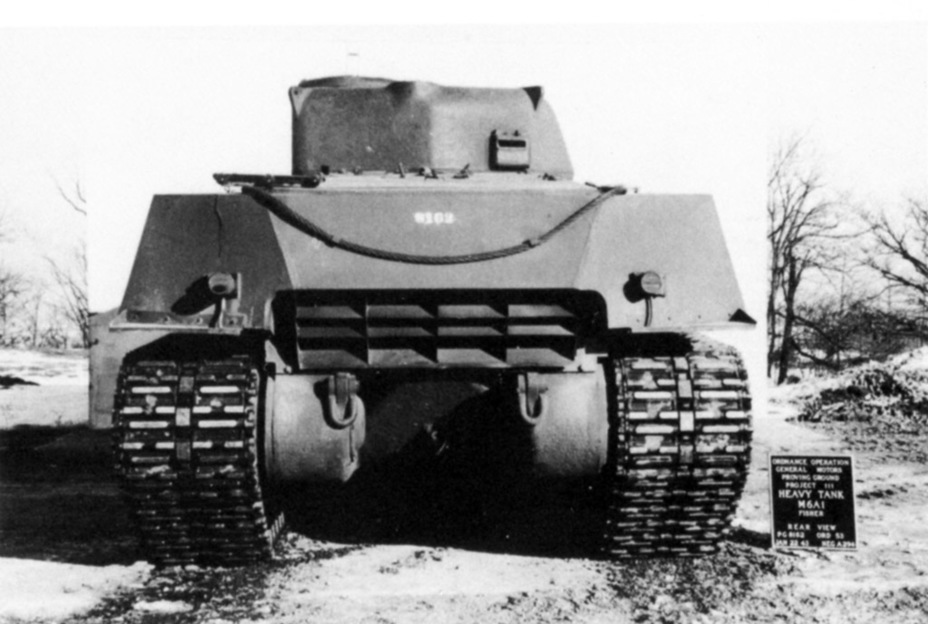

The new heavy tank was noticeably different than any existing American tank. The only similar component was the suspension bogeys, but even they had a horizontal placement of the volute springs. The track links were similar, but significantly wider. The transmission was in the rear of the tank, and the turret was as far forward as possible. The idlers were put as far forward and as high up as possible to improve obstacle the crossing ability of the tank. Skirt armour was added to protect the suspension. Various changes meant that the tank's mass was higher than expected and reached 57 short tons (52 metric tons).

The T1 program was on schedule by the summer of 1941. The country's military brass were optimistic about heavy tank development. The British were also interested. Michael Devar, the head of the British tank mission, stated that Britain was prepared to order 500 such vehicles via the Lend Lease program if the development was a success. However, the assembly of the experimental Heavy Tank T1 was late. The tank was still lacking its T9 cannon on August 19th. The Heavy Tank T1E2 variant was assembled, as the Hydra-Matic transmission never arrived.

The prototype took its first steps on August 21st. The testers remarked on how easy it was to control. Unfortunately, the gearbox broke during the first trials. Defects with the differential were also spotted.

The issues were corrected by September 10th, and the tank set out once again. A top speed of 38 kph was achieved. Overheating of the brakes was noticed. The vehicle performed well in off-road driving trials. The issue of mass production was raised in light of these successes. Production of 50 tanks for the American army and 50 for the British was planned. Work on the electric transmission would continue in parallel. The Heavy Tank T1 program was not cheap. It cost $750,000 by October 31st, 1941.

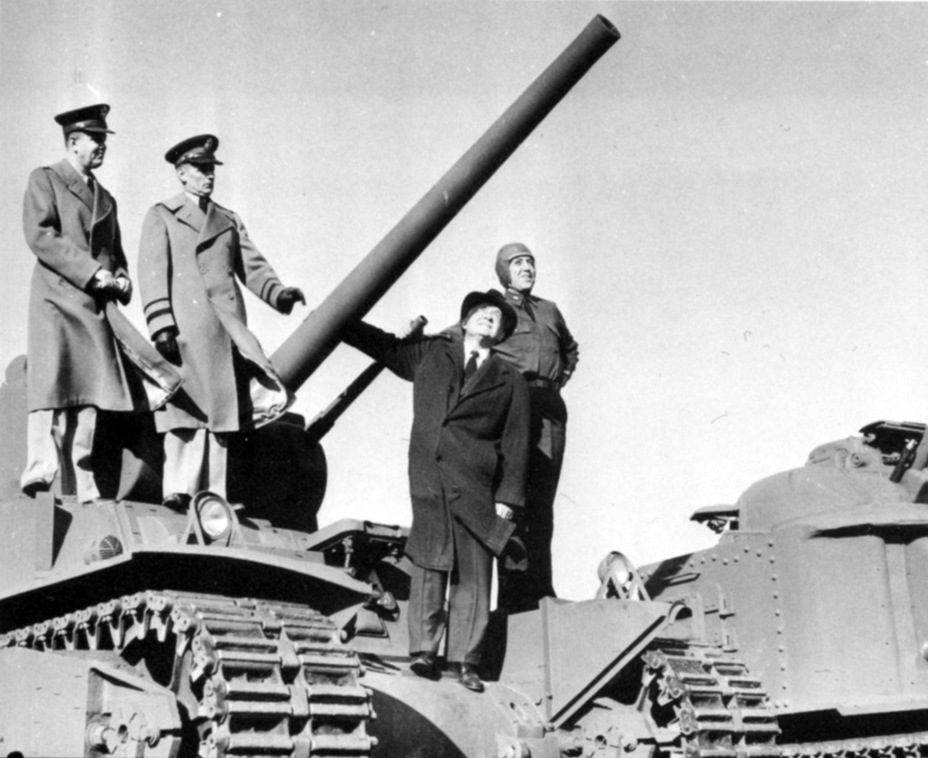

November was full of changes to the Heavy Tank T1. An official demonstration of the T1E2 was only scheduled on December 8th, and even that was after enormous pressure from above. This happened on the next day after the attack on Pearl Harbour, and the new tank immediately became a popular subject for the press. The vehicle was not yet in service with the army, but it was already fighting on the ideological front. Development continued, including the Heavy Tank T1E1. Work on the electric transmission was never stopped, since it had its advantages.

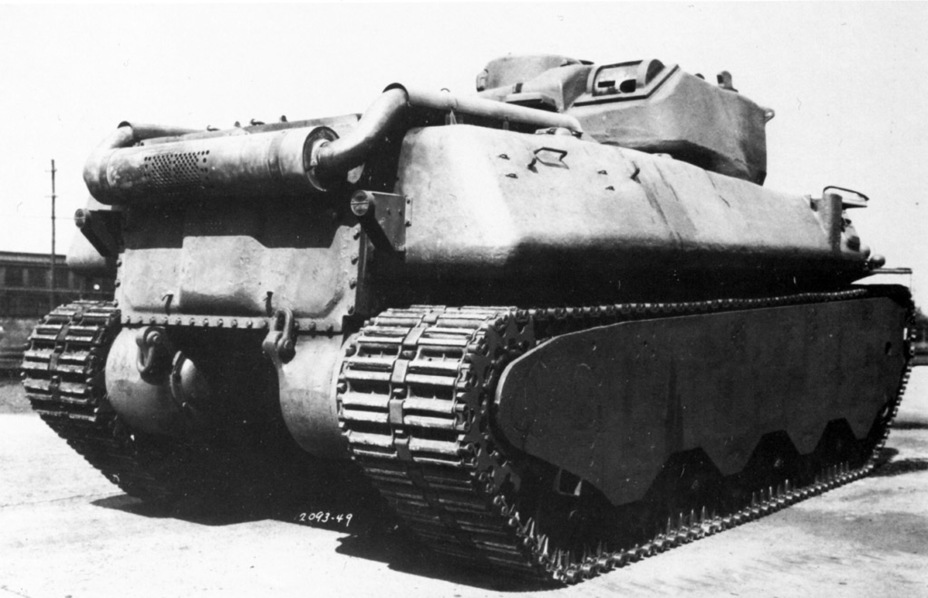

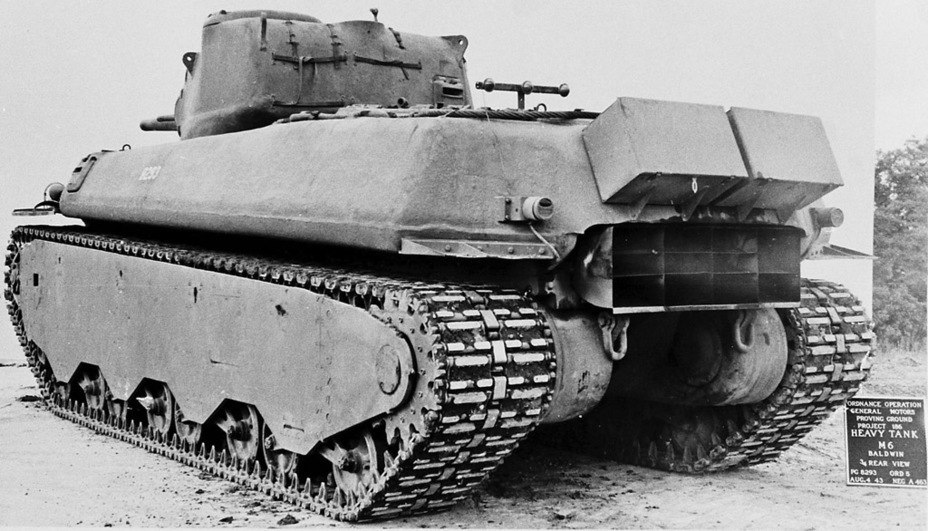

In late January of 1942, after more than a month of trials, the Heavy Tank T1E2 returned to the Baldwin Locomotive Works. The vehicle underwent some serious changes. The biggest change was in the exhaust system. The designers removed the massive muffler and replaced it with a smaller one, hidden inside the hull. There were other changes. The brakes were replaced with an improved variant, developed by the Budd company. Another change, rejected in its infancy, was the armament. A proposal was made by the British on February 17th to install a 17-pounder gun. Barns rejected this proposal, since the tank already had a 76 mm gun.

Work on the Hydra-Matic suspension restarted in February. However, all that meant was that it was eventually delivered to the Aberdeen Proving Grounds. The gearbox was never installed in a tank.

The Heavy Tank T1E2 had a different fate in store for it. Trials, which continued at the Aberdeen Proving Grounds after February of 1942, went well. The modernized vehicle was accepted into service on April 13th, 1942. It would be logical to expect the standardized index to be Heavy Tank M1, but the Ordnance Committee decided otherwise. The tank was named Heavy Tank M6. There were already several M1 tanks, and the addition of another one would introduce confusion. The Heavy Tank M6 was preceded by the Light Tank M5 and succeeded by the Medium Tank M7.

A variety of hulls and transmissions

The tank was not simply renamed when it became the M6. Knowing that mass production might have issues, especially when it came to hulls and transmissions, the Ordnance Department decided to add some variety to the Heavy Tank T1 family. The Heavy Tank T1E3 with a welded hull was introduced. It did not differ from the T1E2 in any other way, and was thus immediately accepted into service as the Heavy Tank M6A1. This happened before a prototype was even built. This was not enough, and another vehicle appeared at this time, the Heavy Tank T1E4. It would be equipped with a quad GM 6-71 engine and a Hydra-Matic gearbox. This tank would also have a welded hull. This variant did not exist for long, and it was cancelled on July 11th, 1942. The Heavy Tank T1 development program was also halted on that day.

Requirements for the heavy tanks were changed once again shortly before that, on April 13th. Their mass was now estimated at 60 short tons (54 metric tons). The armament now consisted of a 76 mm T12 and coaxial 37 mm M6 guns with a vertical stabilizer. The number of M1919 machineguns in the hull was reduced to one. The thickness of the front armour increased to 127 mm, and the top speed of the tank was reduced to 37 kph. Overall, the specification was identical to the capabilities of the Heavy Tank T1E2, aside from the armour and weight.

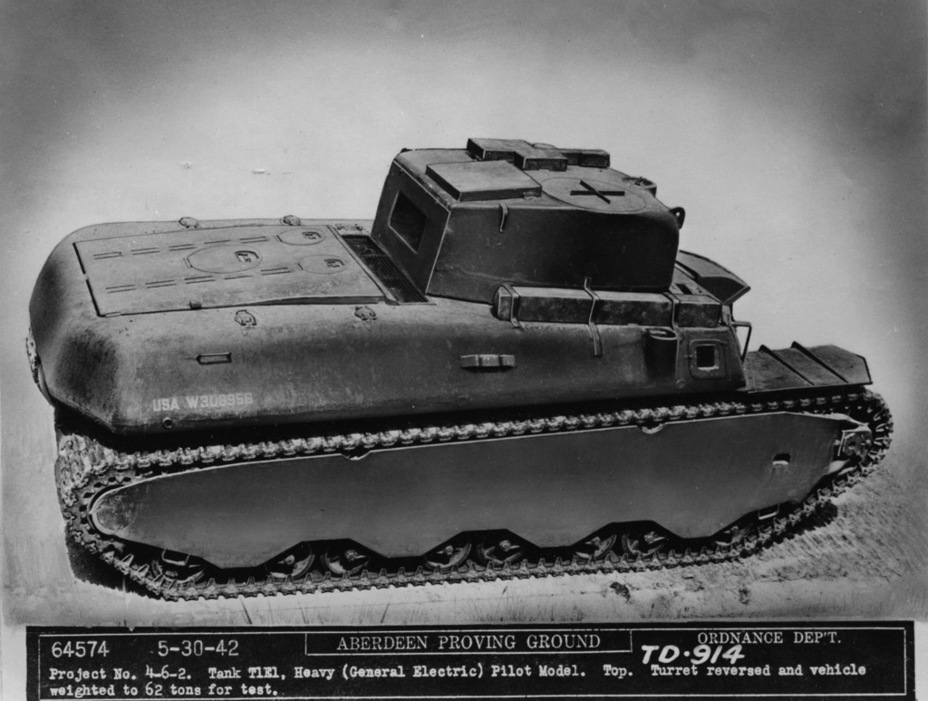

The road to mass production was much longer than it was assumed when the tank was accepted into service. The Ordnance Department did not lose hope that the electric transmission would be completed. General Electric finished work on an experimental prototype of the transmission by early April. Barnes, Colonel Christmas, and other representatives of the Ordnance Department arrived in Erie on the 21st. They were shown the Heavy Tank T1E1, and the results were considered satisfactory. Assembly of the tank was completed on April 30th, and the tank arrived at the Aberdeen Proving Grounds by May 28th.

Unlike the T1E2, the tank with an electric transmission arrived without armament. The idea in this case was just to test the transmission. The T1E1 could be visually distinguished by a larger transmission block in the rear part of the tank. The first trials caused Barnes to experience, if not outright joy, then definitely some positive emotions. In his words, this was the best performance he had ever seen. Barnes recommended the development of an electric transmission for light and medium tanks. Work on light tanks was never done, but the medium T23 reached mass production, if not standardization.

The success with the electric transmission also piqued the interest of the British military. On June 24th, the Heavy Tank T1E1 was shown at the Aberdeen Proving Grounds. Its top speed was only 32 kph, but other characteristics were superior to the tank with a mechanical gearbox. It was easier for the driver to steer the tank than the driver of an ordinary light tank. The impression was somewhat soured by the breaking of a drive sprocket. The breakdown extended the trials, which continued into August and September of 1942. The Ordnance Committee was prepared to standardize the T1E1 as the Heavy Tank M6A2 in late August, but this never happened. However, the T1E1 was still considered the higher priority. A decision to build 115 tanks of this type was made on November 5th, 1942.

A rather interesting situation occurred in late 1942. The American army already standardized two heavy tanks, the M6 and M6A1. The T1E1 was not standardized, but this was the preferred tank. The following decision was made in the end: the M6 and M6A1 would be sent to the British, and the T1E1 would be used in the American army.

Evolution without demand

Work on improving other members of the T1 family continued in parallel with improvements to the T1E1. A meeting was held on October 22nd, 1942, discussing the changes to the tank's armament. A proposal was made to remove the 37 mm gun and replace it with a Browning M1919 machinegun. This was a reasonable solution, as the coaxial gun already had limited performance against tanks. The two Browning M2HB machineguns in the hull would also be removed.

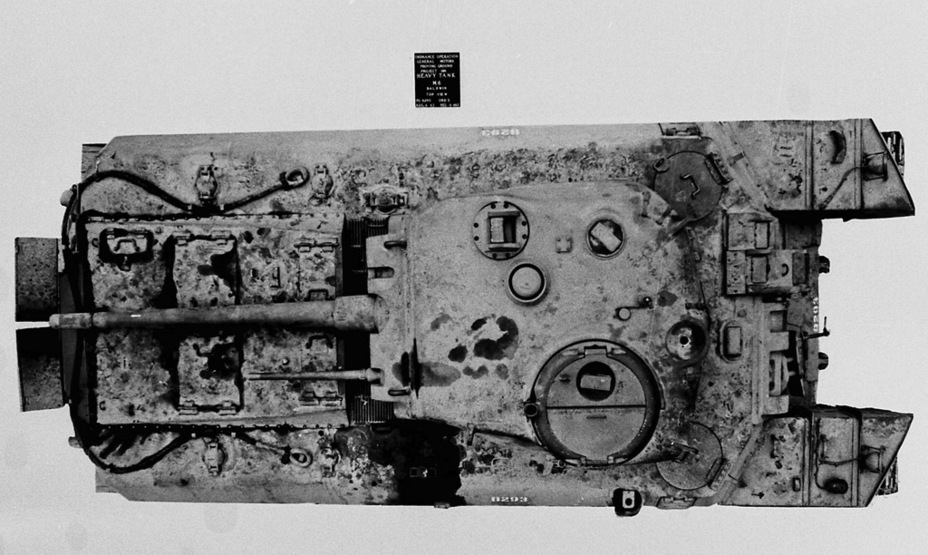

The coaxial gun was never removed, but some changes were made. The Browning M2HB AA gun in the turret was removed, since it was rather ineffective. The commander's cupola and its machinegun were also removed, replaced with a hatch from the Medium Tank M4. In case of emergency, a Browning M2HB machinegun could be mounted on the cupola. The turret was changed somewhat. The hull also changed as a result of trials. Specifically, the driver and assistant driver's hatches are different on mass produced T1 tanks. In addition, production M6 tanks had large toolboxes on teh back. Based on the attachments, they could also be installed on the T1E1.

The mass production of the M6 and T1E1 began almost simultaneously. The first vehicles were ready by the start of December of 1942. The start of production at the Baldwin Locomotive Works coincided with some sad news. Operation Torch began on November 8th. American troops landed in Morocco, with offensives towards Algiers and Tunis. Despite the fact that fighting in the first few weeks was not particularly fierce, valuable information was obtained by American soldiers, including the tankers. It turned out that two medium tanks were often more effective in a real battle than one heavy one. A 60 ton tank was hard to transport over railroads, and its top speed was low. After analyzing the results of a month of combat in North Africa, the American armoured command decided against the production of heavy tanks on December 7th, 1942.

Despite this decision, work on the heavy tanks did not stop. Mass production was retained, although in miserly amounts. It often happened that unneeded vehicles suddenly became necessary. In addition, the German forces in Africa received their first heavy tank, the Tiger Ausf. E, in late 1942.

The question of upgunning the T1E1 with a 90 mm gun was raised on December 10th. Practical work began some time later. The issue of removing the 37 mm cannon was raised once more on December 28th, which did not prevent it from being installed on every production T1 tank. The Aberdeen Proving Grounds requested one sample of each tank for trials.

The production run size was settled on March 25th, 1943. There was no more talk of a large batch. The most numerous member of the family was the T1E1. 20 units were built. The Heavy Tank M6A1 was second, at 12 units. Only 8 Heavy Tanks M6 were built. Fisher Body delivered the first M6A1 in March of 1943, and the last T1E1 left Baldwin Locomotive Works in February of 1944. Overall, 43 T1 family tanks were built, including prototypes.

The heavy tanks were not destined to see the front lines, but they were issued to the army. The experimental T1E2 was one of the best heavy tanks in the world when it entered trials in August of 1941. It had superior armament to the Soviet KV-1, its front turret and hull armour was thicker, and the mobility was about equal. However, the rapid development of armoured vehicles during the war resulted in a very negative evaluation in the summer of 1943. The armament did not match the size and mass of the vehicle, and there were many complaints about the crew stations and aiming system. The American tankers rejected the Timken gearbox. The overall verdict was damning: a complete redesign of the hull, fighting compartment, and transmission was needed.

On August 2nd the American armour commanders remembered their decision to not use heavy tanks. Instead, work on the T25 and T26 medium tanks would be accelerated. In order to somehow save face, the Ordnance Department offered to send 2 Heavy Tanks M6 and 6 Medium Tanks T23 to the British in November of 1943, but nothing came out of this proposal either.

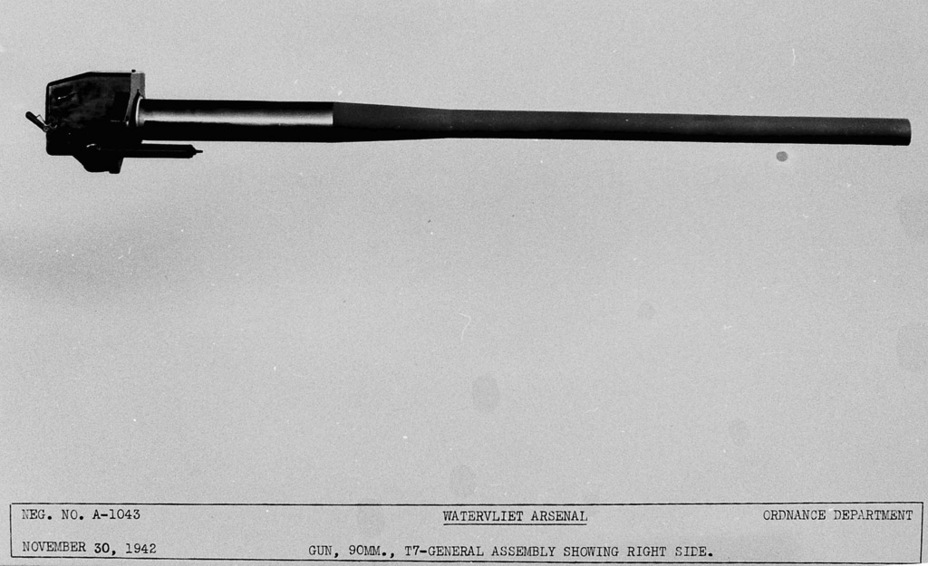

The Ordnance Department began thinking about the disproportionately weak armament in the fall of 1942. The result was the 90 mm T7 gun. It had the ballistics of the M1 AA gun. The first T7 prototype was ready by the end of November of 1942. As mentioned above, the order to install it into a turret of the T1E1 was given on December 10th. It was carried out with great delay, only on March 10th, 1943. Firing trials that started in late March of 1943 showed that this conversion was good. The oscillations during firing were within acceptable limits. However, there were now issues with firing the coaxial 37 mm gun.

The new gun could not save the heavy tank. The idea of installing the same T7 90 mm gun into the T23 tank came up in the summer of 1943. The result was the T25 and T26. These tanks were much lower and lighter. There was no reason to develop a heavier tank with worse mobility.

Unlike the British, Soviet specialists were not permitted to get close to the heavy tank. A group of Soviet specialists managed to familiarize themselves with the M6, but information was scarce. For instance, no one mentioned the T1E1 and its electric transmission. It was mentioned that American heavy tanks have the most acceptable silhouette of all American tanks. The M6 was still too tall for Soviet engineer, however. The specialists noticed the low ground pressure and a complex torque converter. Nobody mentioned to the Soviet guests that the US Army had already given up on the tank. The tank was never observed in motion, as it was partially disassembled. Overall, the Soviet side evaluated the tank as on par with domestic designs of the same class, although a little poorly thought out.

Only one tank from the T1 family survives to this day. This is one of the production T1E1s that was sent to the Aberdeen Proving Grounds for various tests. Today it is kept in storage at Fort Lee, where a major museum is being planned.

The Americans created a very good tank. However, too much time was spent on its improvements. even worse, there was no room for a heavy tank in the American armament system by the time it was accepted into service. It's worth noting that the decision to discard heavy tanks came back to bite the Americans. When a heavy tank was needed in the summer of 1944, it did not appear out of thin air.

Translated by Peter Samsonov. Read more interesting tank articles on his blog Tank Archives.

Sources:

- National Archives and Records Administration;

- Firepower — A History of the American Heavy Tank, R.P. Hunnicutt, Presidio Press, 1988;

- Author's photo archive.