On July 20th, 1941, the Red Army adopted the T-60 small tank into service. This was a necessary measure, as incredible losses of tanks in the first month of the Great Patriotic War had to be replenished, and mass production of the T-50 wasn't getting off the ground. Even if the goal of producing 10,000 tanks in 1941 was not met, large amounts of T-60 tanks entered service in October, playing an important part in the defeat of the Germans at Moscow. At the same time, an idea to modernize the T-60 was tossed around as early August, resulting in a heavier tank that was indexed T-70. What is the history of this tank?

First, a Turret

Initially, the T-60 was to be armed in the same way as its predecessor: a large caliber DShK machinegun with a coaxial DT. By late July, it was discovered that this was impossible. The industry could not produce required amounts of DShK machineguns. A replacement gun was found quickly: the 20 mm ShVAK aircraft autocannon, and the tank TNSh gun was created by combining wing mounted and turret mounted variants. The first gun was trialled in August of 1941. Already, complaints were made regarding the gun's insufficient firepower:

«The installation of a 20 mm ShVAK gun in the turret of the T-60 tank does not solve the issue of improving penetration, especially against modern targets with 15-20 mm of sloped armour. The commission considers it necessary to accelerate work on producing more effective armament for the T-60 tank."

A logical solution was the installation of a more powerful weapon than an autocannon. Work on installing such a gun was initiated by the Artillery Committee of the Red Army Main Artillery Directorate (Artkom). In September of 1941, a meeting was called where representatives from two design bureaus were invited: Molotov GAZ and factory #92. After studying captured vehicles, a decision was made to arm the T-60 with a 45 mm mod. 1938 gun. According to the requirements, the stock turret was preserved.

Initially, work to improve the armament was done jointly by the GAZ and factory #92 design bureaus. However, the designers quickly diverged in their opinions on how the armament should be installed. The result of factory #92's work was covered in a separate article. This article will talk about what the Molotov GAZ design bureau came up with.

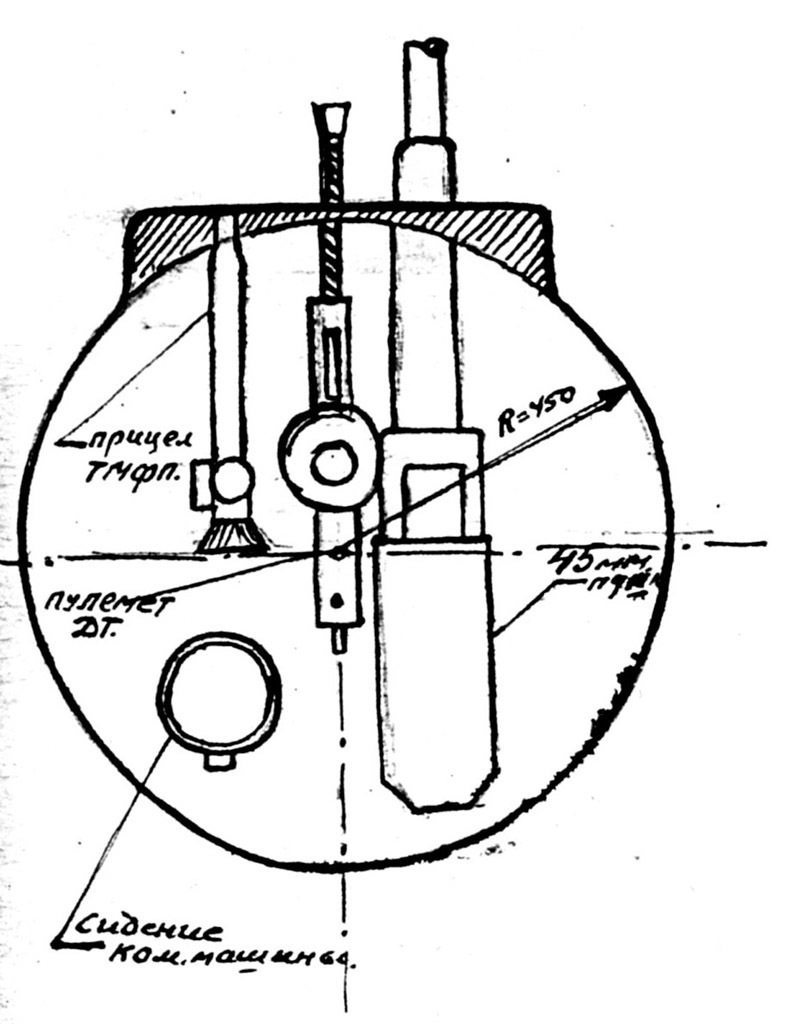

The task that the Artillery Committee gave was not an easy one. The small turret with a 900 mm turret ring had to house a cannon, a coaxial machine gun, a sight, and leave enough room for the commander, who also doubled as a loader and gunner. The designers had to radically alter the placement of components to achieve this goal. The 45 mm gun was moved all the way to the right, and the machinegun was installed in the center. The telescopic sight was on the left. Thanks to this layout, the commander had at least some room in the left rear part of the turret.

Because of the new location of the armament and the commander, the turret traverse and gun elevation mechanisms had to be moved, as well as the ammunition racks. Even though the GAZ variant required more changes than the factory #92 proposal, it was preferable, since it left more space for the commander. Unlike their competitors, GAZ did not provide documentation. Their gun mount was built and tested. Even though it was rough around the edges, the existence of a prototype was a serious boon for the GAZ project.

Both designs, presented on December 20th, 1941, had their advantages and drawbacks. One problem was that the 45 mm mod. 1938 gun was heavier than the TNSh, and installing it made the turret unbalanced. This means that turning the turret when the tank was tilted at a large angle was difficult. In order to balance the gun, a proposal was made to add a 30 kg weight to the brass catcher.

After installing a larger gun, the already cozy turret became even more cramped, and working with aiming mechanisms became harder. The fact that the commander still loaded the gun didn't add any comfort. The belt-fed TNSh compensated this drawback as it did not have to be loaded with every shot. After installing the 45 mm gun, the commander's workload increased, which reduced the effectiveness of fire in battle.

According to a memo written on December 20th, GAZ and factory #92 were to complete the rearmament on January 15th and 25th respectively, perform gunnery trials, and give conclusions. Even at this stage, the GAZ design was preferred.

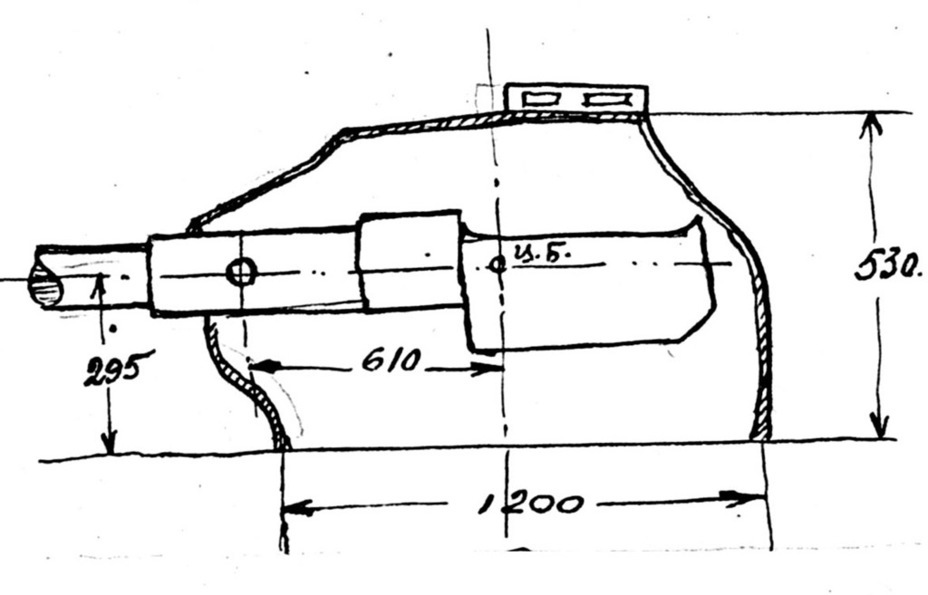

Meanwhile, a group of engineers from the GAZ design bureau led by V.A. Dedkov proposed a serious redesign of the turret. The turret ring diameter was increased by 25-30 mm, the air intake in the front of the turret was removed and moved to the turret hatch. Instead of a welded design, the turret was cast. According to a report dated December 30th, 1941, the new turret was accepted into the experimental work plan with the due date of January 25th, 1941.

In practice, the situation with the new turret developed differently. Further work determined that it was necessary to increase the turret ring diameter to 966 mm. The gun mount had to be carried even further forward, and a bustle was added to increase space in the turret. In the end, nothing was left from the initial T-60 design. The layout of the armament was the same as in the initial armament replacement design.

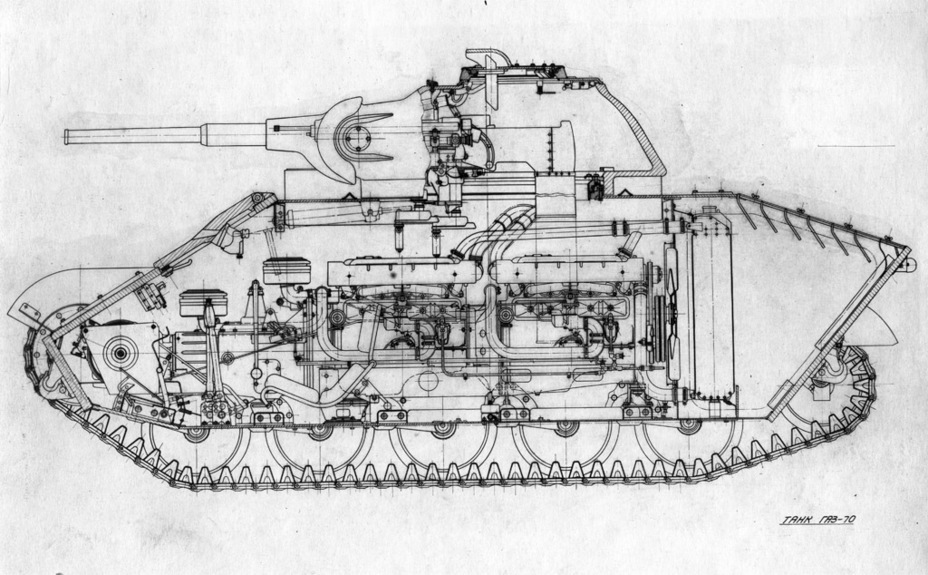

The growth of the turret in size and mass prompted a redesign of the entire T-60. N.A. Astrov led this project, which began in the end of 1941. Modern publications sometimes call this project «070», but this is nothing more than creativity on the part of individual researchers. This index was never used in reference to the tank, and is completely uncharacteristic of the Molotov GAZ design bureau. In reality, the tank had an internal index of GAZ-70 and design documentation used the code 70.

The overall layout of the T-60 was preserved, but the tank radically changed. An increase in mass required a stronger engine. It was assembled from two GAZ-11 model 202 engines connected together lengthwise. The resulting engine was indexed GAZ-203. Instead of a gearbox from the GAZ AA truck, the gearbox from the ZIS-5 truck was used.

The longer engine meant that the tank increased in length. With the new hull, GAZ engineers omitted the driver's cabin and replaced it with a sloped plate and a massive hatch in which an observation device was installed. The suspension was also changed. The number of road wheels was increased to five per side and the torsion bars were reinforced. Instead of a modernized T-60, the GAZ design bureau ended up with a whole new tank.

Better Across the Board

The design of the GAZ-70, which later received the official index T-70, continued throughout January and reached its final stages in early February of 1942. Work on a prototype started by February 10th, and it was completed on February 14th. By February 19th, a trials program was finalized for the T-70 tank.

The experimental tank surpassed the T-60 in every category. The width was identical, but the width increased by almost 20 cm and the height by almost 15 cm. The mass of the new tank reached 9 tons.

The armour was also improved, and this fact is worthy of detailed exploration. Efforts of various domestic historians created the legend that the T-70 had equivalent armour to the T-60, which was improved after trials. However, this legend does not match up with the report on the trials of the experimental T-70 tank. According to the document, the central front plate was 45 mm thick and the upper front plate was 35 mm thick, same as on the production tank. This cannot be considered identical armour to the T-60, which had a 35 mm thick central plate and 15 mm thick upper plate.

The assertion that the tank had insufficient off-road performance is also incorrect. This can be seen in the trials report on the first day:

«Driving off-road in the snow, 40-50 cm deep:

- 50 km was traveled.

- Average speed: 13 kph.

- Traveled on other roads: 25 km.

The T-70 traversed the snow in third gear with infrequent shifts to second gear. The T-60 tank could drive across similar terrain only in first gear, and rarely in second gear. The average speed of the T-60 tank crossing the same terrain is half as much as that of the T-70."

The GAZ-70 reached an average speed of 18-20 kph off-road, and the fuel expenditure was 200 L for 100 km. The tank traveled 106 km on dirt roads at an average speed of 20-24 kph at the cost of 160 L of fuel for 100 km. On the highway, the T-70 traveled 130 km with an average speed of 32 kph and maximum speed of 45 kph, expending 100 L for 100 km. These results were deemed satisfactory.

During trials, the maximum grade was established to be 25 degrees. At higher angles, the tracks lacked traction. The tank also toppled a pine tree with a 25 cm thick trunk during trials.

Assertions that the testers had complaints about the comfort of the tank are also false. In total, 266 shots were fired during trials, with a rate of fire on the move of 4-5 RPM, with a satisfactory precision. There were no complaints about the fact that the turret only holds one man in the report. In addition, the report straight up says that the crew positions are comfortable.

The commander's vision was also deemed satisfactory. The appearance of the turret periscope reduced the commander's dead zone to 6-8 meters. However, later investigations showed that it was actually 9 meters.

The following conclusions were made:

«The combat and tactical abilities of the T-70 tank significantly surpass those of the T-60, components of which are used in the T-70 design.

- All main characteristics of the tank: armament, armour, average speed, maneuverability, performance in the snow and on dirt roads, and visibility surpass those of the T-60 tank, making the T-70 tank a light tank that can combat light anti-tank artillery, light and small tanks, infantry, and enemy mechanized forces, as well as serve as an infantry support tank.

- The light T-70 tank can be accepted into service and put into mass production to replace the T-60.

- All noted defects must be corrected by the factory.

- In parallel with producing the T-70, GAZ must continue testing the reliability of components in spring and summer conditions."

Welding is Better

A decree by the State Committee of Defense (GKO) #1394 titled «On the organization of production of T-70 tanks at the Molotov Gorkiy Automotive Factory» was issued on March 6th, 1942. According to the decree, the production of T-60 tanks would be reduced gradually. On May 1st, 1942, production of the T-60 ended. The first 20 T-70 tanks were expected in March, then 150 tanks in April, 260 in May and 390 in June.

Three days later, the number of factories making the tank was increased to three. Decree #1417ss titled «On the production of T-70 tanks at factories #37 and #38» was issued on March 9th. It ordered cessation of production of the T-60 at factory #38 in Sverdlovsk by May 1st and at factory #37 in Kirov by June 1st. Sverdlovsk would ship its first 10 T-70 tanks in April, 75 in May, 125 in June, and 175 in July. Kirov would produce 20, 70, 120, and 150 tanks. Factory #37 management managed to convince Molotov that they could not begin production of the T-70 in such a short time, and production of the new tank was postponed until the third quarter of 1942.

In addition to correcting defects discovered during trials, decree #1394 ordered production of the T-70 with widened track links, wider road wheels, and wider grousers to begin on June 1st, 1942. This was caused by the fact that pressure on each road wheel grew from 700 kg on the T-60 to 900 kg on the T-70. The trials commission considered it acceptable to use existing T-60 suspension elements on early tanks.

Another wish of the commission was connected with the tank's armour. The thickness of the sides was 15 mm, same as on the T-60. It was proposed to thicken the sides to 25 mm, at the cost of armour from the upper front plate (30 mm instead of 35). This idea was rejected, and the T-70 entered production with the same armour as the prototype. As for the reinforced suspension, it entered production long after the GKO deadline.

As with the T-60, the mass production of the T-70 was no easy task. Production of hulls and turrets was the limiting factor. Factories #176 (Dzerzhinskiy Locomotive Factory in Murom) and #177 (Vyksa Particle Size Reduction Equipment Factory) were the subcontractors for these components. Murom planned to produce 25 T-70 hulls in March, 135 in April, 190 in May, and 290 in June. 10, 40, 90, and 150 hulls would be built in Vyksa.

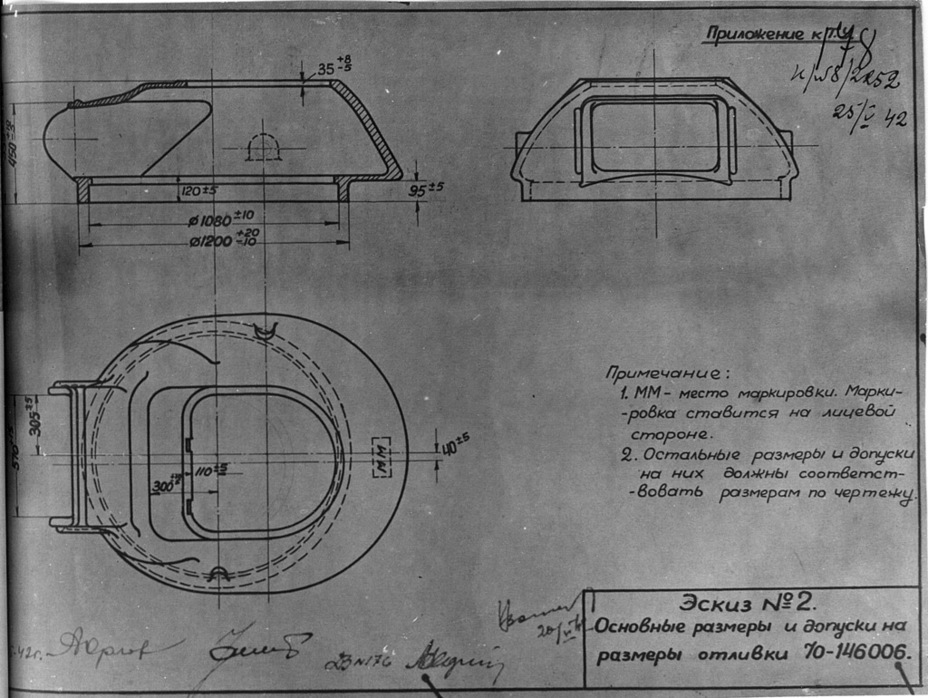

The issue with turrets was a tricky one. Initially, it was planned that the tanks would use cast turrets, 40-45 mm thick, almost identical to the experimental turret. However, GKO decree #1394 also mentioned a 30-35 mm thick welded turret. This turret was hurriedly designed by the GAZ design bureau by March 20th. Meanwhile, no one refused the cast turrets: according to the decree, factory #178 (S.M. Kirov Metallurgical Factory in Kulebaki) would produce 10 turrets before March 10th, and 10 more by March 20th.

In practice, things were more difficult. Preparation for the T-70 at GAZ reduced the output of T-60 tanks, and over a 12 day period, no tanks were shipped at all. Additional problems were caused by interruptions in supplies of parts.

The torsion bars were a particularly problematic component. In addition to problems with shipments of metal, there was a large amount of rejected parts, which also impacted T-60 production.

As for the T-70, instead of the 20 tanks planned for March, 3 were completed, 2 of them without turrets. The promised hulls and turrets never arrived from the subcontractor factories. GAZ decided to build them locally. A batch of 25 hulls was started, but shortages of metal of required thickness killed the attempt. Only 5 hulls were assembled, 2 of which had no turret platforms. The upper from plate was assembled from two plates (20 + 13 mm) because of a lack of 35 mm thick armour. All hulls also lacked driver's hatches, which were installed later.

The first welded turrets were also assembled with two layers (20 + 13 mm). 17 of these turrets were started, but not a single one was ready by the end of March. As for the cast turrets, 8 were built in March, but only one was completely finished.

Shipment of hulls from subcontractors only began towards the end of March. 5 sets of hulls arrived from factory #176, and as of April 1st, their status was in assembly.

In addition to issues with hulls, there were problems with the engines. ZIS didn't supply GAZ with ZIS-5 gearboxes. Tanks continued to be produced in an improvised fashion, and real mass production was estimated by Senior Military Representative Okunev to begin on April 10th.

Real production of the T-70 began on April 1st. In the first 10 days, 8 out of the planned 15 tanks were accepted. By the 10th, the factory had 35 hulls, 14 of which were in the process of assembly. Production was off to a rough start: out of 13 tanks finished by April 12th, 7 burned out their clutch, 3 needed new final drives. three tanks lurched to the side, two had their engines replaced, and another two had defective gearboxes. Some of these problems were manufacturing defects.

In total, 50 tanks out of the planned 170 were accepted in April. 33 more tanks were in the process of being assembled. Another unpleasant fact that that out of all tanks built in March and April, only 19 were shipped to the army, and 33 more remained at the factory where they were undergoing repairs.

The main cause of the defects was that the production technologies were not fully mastered at the factory. The most common problem with the T-70 at the time was overheating of the engine.

As for the supply of hulls, 132 units arrived in April. There were many complaints about the hulls regarding the welding. Even more complaints were made about the turrets. 8 of the hulls had cracks. The GAZ hull plant had to compensate for these problems, which impacted other work. Representatives of factories #176 and #177 were called, who promised to rectify the problems.

As for other defects, Astrov and the chief designers of GAZ, A.A. Lipgardt, notably improved the design of the tank. 43 hull blueprints out of 164 were changed, 18 engine blueprints out of 79, plus 8 new blueprints were introduced. Improvements continued.

These issues should not surprise anyone or cause them to think that the T-70 was a bad tank. It was designed in a rush and, unlike the T-60, was largely a new vehicle, and almost twice as heavy at that. The situation with hulls was solved by the end of May, other issues were gradually resolved as well.

During these improvements in production, the cast turret vanished. Out of the 20 planned turrets, factory #178 built only 9 in March and delivered only 5. This was connected in part with delays in transfer of documentation. 10 turrets were built in April, 5 in May. Then production of cast turrets stopped, as the factory began producing cast driver's hatches and gun mantlets. Nevertheless, 15 more turrets were delivered in June of 1942. In total, GAZ received 47 cast turrets.

According to some domestic historians, these turrets were worse than the welded ones, but it's hard to agree. The only drawback was a heavier weight, 992 kg vs 876 kg of a welded turret. Otherwise, the cast turret was no worse than a welded one. Unlike the T-34, where the cast turret became the main one, the welded turret was fine for the T-70, especially since there was nowhere to produce cast turrets.

Cast turrets never panned out at factory #38 either. Production preparations only began in March of 1942. Due to problems with ZIS-5 gearboxes, not a single GAZ-203 was sent to the factory in March. There were also issues with cast components. As of April, only 2 cast turrets and 5 hulls were produced in Kirov, and another 10 hulls were under construction. Later, factory #38 began producing welded turrets. 7 tanks were shipped out of the 20 planned.

Continuing issues with engine shipments caused the GKP to issue decree #1898ss on May 4th, 1942, reducing the May quota of T-70 tanks for Kirov to 50 units. As with GAZ, production began to match the requirements more or less by the start of the summer.

As for factory #37, only 10 T-70s were built. It happened in July of 1942. On July 28th, decree #2120 titled «On the production of T-34 tanks at Uralmashzavod and factory #37» was issued. By September 29th, the reorganized factory #37 (now factory #50, a part of UZTM) built its first two T-34s. T-70 parts that were already done were transferred to factory #38.

Translated by Peter Samsonov. Read more interesting tank articles on his blog Tank Archives.