To a casual observer, German tank industry was like a jack in a box. 15 years after the end of WWI it suddenly sprang to life and began to crank out world class designs. However, there is no such thing as miracles. In addition to German specialists like Joseph Vollmer and Otto Merker who worked abroad, Germany had its domestic tank program. It was conducted in secret and birthed some very unconventional designs. One of them was the Grosstraktor, a medium tank that became the culmination of German tank building of the 1920s. It was the first step on the way to the PzIV, the most numerous German tank of WWII.

High priority medium tank

The end of WWI triggered a collapse of German tank production. The Treaty of Versailles prohibited Germany from developing of producing tanks or other armoured vehicles. German military command also put in their effort to defeat their own tank designers. It's hard to describe the condition of German tank building towards the end of the war in any other way.

Joseph Vollmer's attempts to restore normalcy were partially successful. Production of the LK-II light tank went slowly and with great resistance from the German military. Some of them continued to dream about steel monsters like the 120 ton K-Wagen. One can confidently say that German generals plainly revealed their own incompetence and amateurishness. Such «successes» meant that work had to start from screatch.

Before working on a new tank, the Germans studied foreign developments carefully. It became clear that German tank design was far behind, especially when it came to light and medium tanks. While the Germans tried to adapt British developments, the British themselves considered those tanks obsolete.

The idea that the «pin cushion of guns» was a dead end was first arrived at by the French. As a result, they produced the FCM 2C, the best tank of WWI, but one that came too late for it. The tank was a stepping stone, and one that the Germans paid close attention to. The concept of a tank with a cannon turret and a machine gun turret was adopted for the German tank. However, it would not be a heavy tank. It would have been too expensive, and the lesson from the A7V that was built in a batch of only 20 was well learned. The Germans initially did not have plans for a light tank either. They were not the only ones to realize that the medium category was optimal: most successes of British tank building in the 1920s were in this space. Some requirements for a German medium tank clearly had British roots.

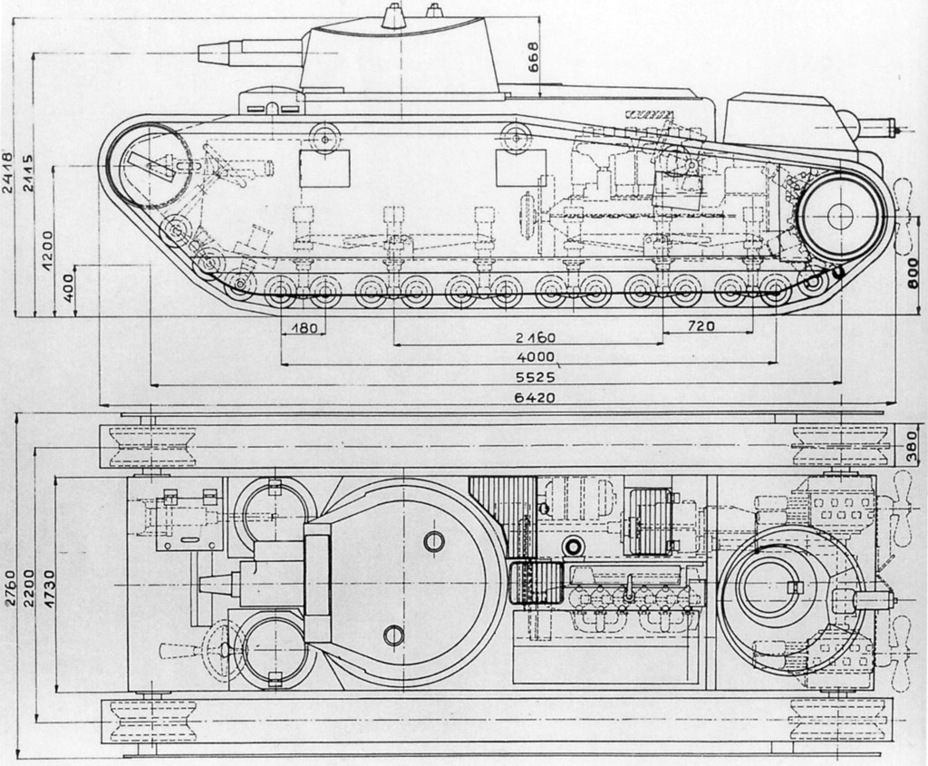

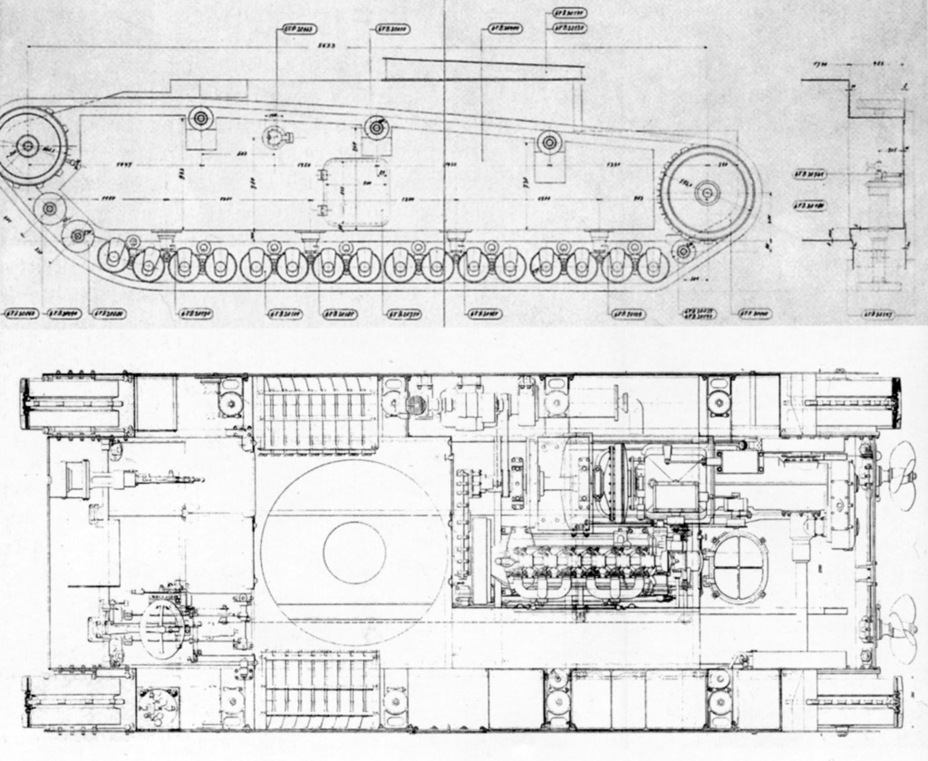

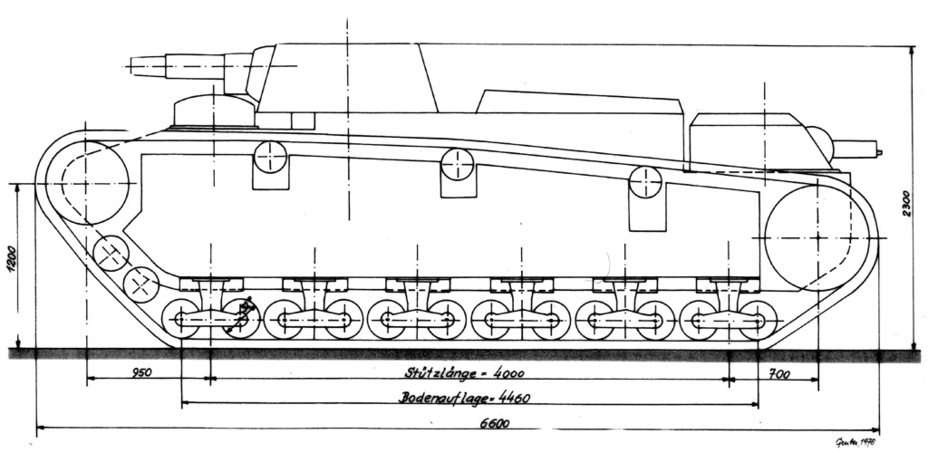

The first requirements for a medium tank named Armeewagen 20 were prepared by May of 1925. According to them, the tank would weigh 16 tons, have a top speed of 40 kph, and a cruising range of 100 km. The tank would be 6 m long, 2.6 m wide, and have a height of 2.35 meters. The 14 mm thick armour would protect it from rifle bullets. The crew would consist of 6 men, including a radio operator. The armament included two machine guns and one 75 mm cannon.

There was also an interesting idea of making the hull watertight. That's right, the German tank was planned as an amphibious vehicle from the very beginning! This requirement did not come out of nowhere. The Germans carefully followed the development of the Medium Tank Mk.D. This was the first amphibious tank, albeit it did not float very well. The Germans also knew that similar developments were underway in the US, not including Christie's amphibious tanks.

Work on the Armeewagen 20 (A.W.20) began within Krupp's conglomerate. They were led by Erich Muller, the chief armaments designer. Muller is known as the creator of a number of weapons systems. At this time, the idea of assigning an artillery designer to work on tanks was normal practice. Along with him, a team headed by Georg Hagelloch and Erich Wölfert worked on the A.W.20. They already had experience working on the Kleiner Sturmwagen, a competitor of the LK-II.

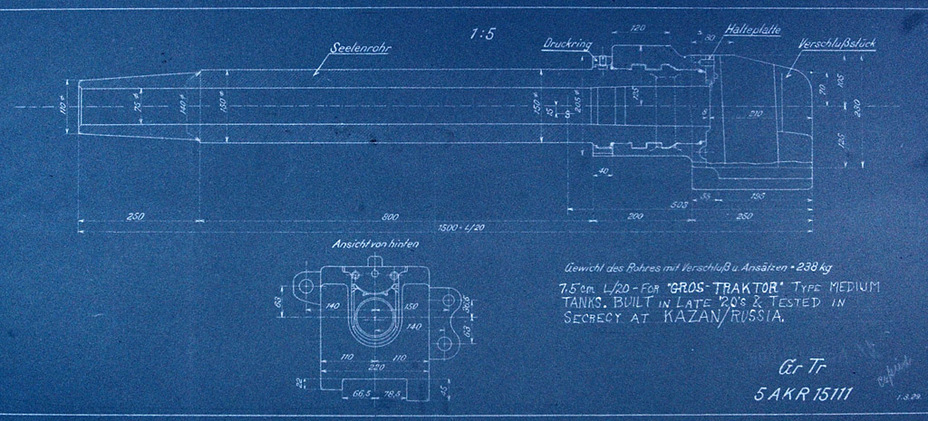

In addition to designing the overall concept, Krupp was responsible for creating a 75 mm gun for it. The 75 mm L/20 mountain gun was taken as the starting point. It was installed in a two-man turret along with a coaxial machine gun. The turret was requested to be as small as possible.

The decision to use a short barrelled weapon was no accident. Sure, it had inferior muzzle velocity to the French 75 Mle.1897, but it was much more compact, and would result in a smaller turret. This was important for a tank weighing 15-16 tons. The HE power of the weapons was about the same. The anti-tank capabilities were also satisfactory, as hardly any tank had more than 20-25 mm of armour in the 1920s.

Three way race

Krupp presented the first designs of the A.W.20 on March 1st, 1927. The work was already a competition. Remembering that a monopoly on tanks in WWI led to poor results, the 6th Department of the Weapons Directorate offered work on the project to two more companies: Daimler-Benz and Rheinmetall. That is about the time that Heinrich Kniepkamp, later a key figure in German tank development, began working in the 6th Department.

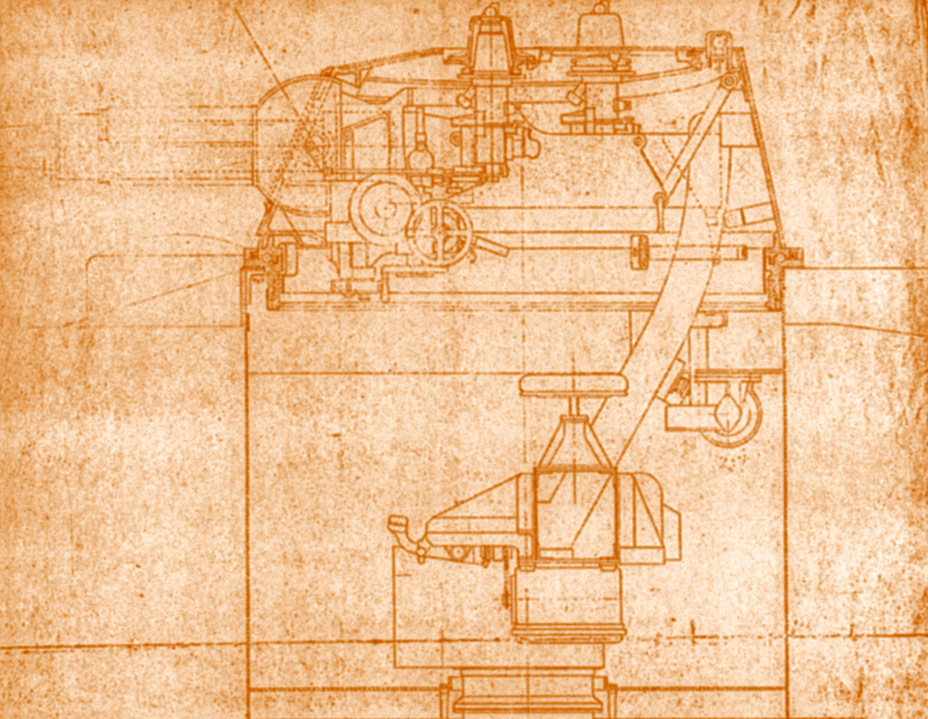

Even tough Krupp now had competition, the center for development was still in Essen. Specifications for the turret and armament were ready on March 19th. The full weight of the turret and gun would be 1660 kg, of which 550 kg was reserved for the gun. The gun mount had impressive elevation range: from −12 to +60 degrees. A special bulge in the turret allowed for increased depression. An electric drive could turn the turret completely around in 30-75 seconds. Without the drive, a sull traverse took 120 seconds. Large hatches were placed in the sides of the turret, a layout that would become common with German tanks.

The tank was also supposed to have a machine gun turret in the rear with a high angle of gun elevation. This machine gun doubled as an AA weapon. A wooden model of the A.W.20 was prepared by March 25th. Its demonstration was met with final approval. On March 30th Krupp received a contract for the development and construction of two tanks.

The competition began even before any prototypes were built. Krupp was the second company that received a contract. The first, Daimler-Benz, received a contract on March 26th. Ferdinand Porsche was in charge of developing Daimler-Benz's entry. Development was also directed by Rudolf Mertz. Since Krupp was already designing a turret, Daimler-Benz was only going to build a chassis.

A contract for two tanks was later given to Rheinmetall. Work in Dusseldorf was headed by Heinrich Romberg, Rheinmetall's chief designer of artillery and military vehicles. Unlike Muller, who was an artilleryman, Romberg had direct experience with tanks. Arthur Gaunitz and Georg Engel were also involved with the chassis. In addition to the development of a tank, Rheinmetall also received the contract for building them.

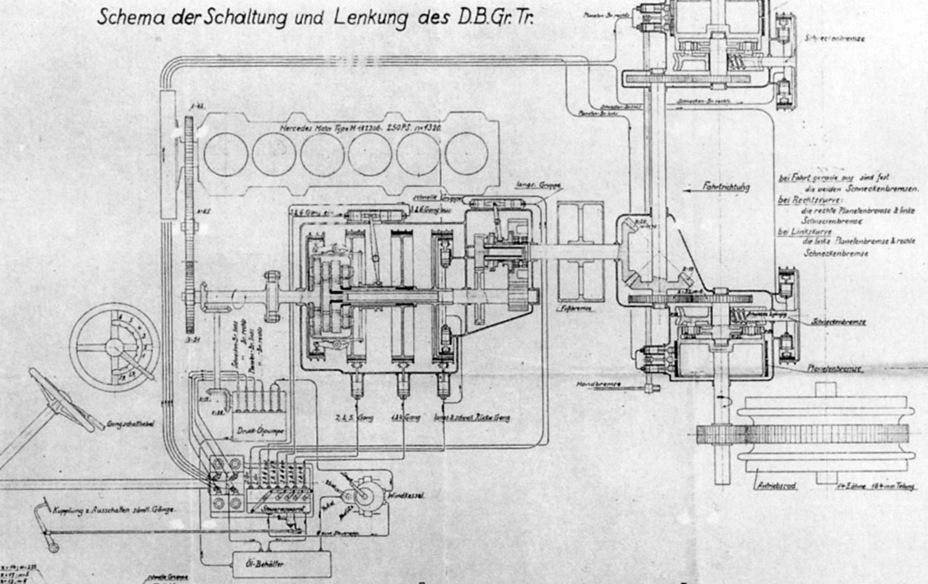

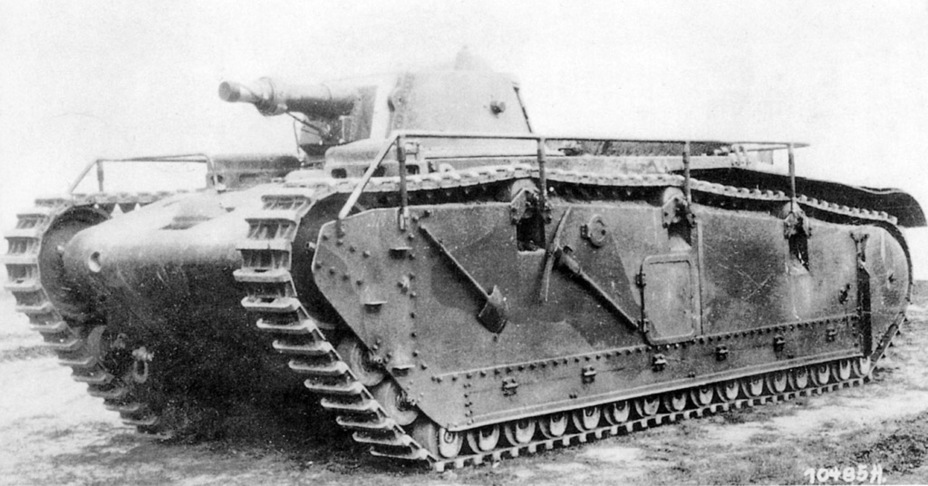

Daimler-Benz did not end up in this race by accident. It was at Daimler-Motoren-Gesellschaft that A7V tanks were built at in WWI. Later, the factory was given the name Daimler-Benz Werk 40. Even though the chassis was being built according to the same specifications as Krupp's, it was radically different from its competitor. The internals were different. The Daimler-Benz IV b. 6-cylinder linear aircraft engine was chosen. This 31.2 L 260 hp motor was developed during WWI for use in heavy aircraft. The engine was the heaviest of all proposed, 604 kg. A secondary motor was needed to start it.

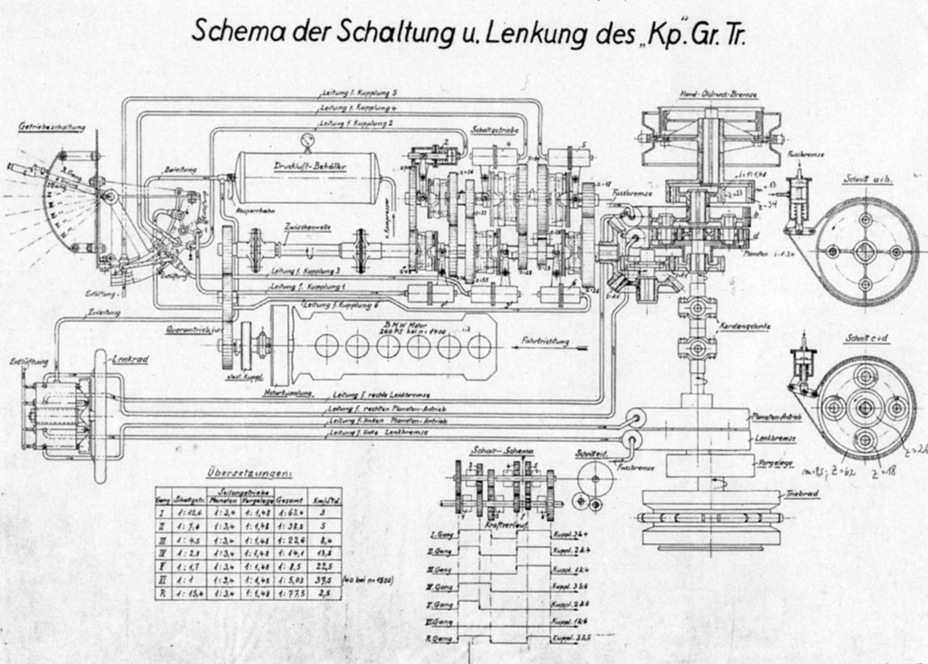

A bulky gearbox with a preselector giving 6 speeds forward and 2 back was installed to the left of the engine. The gearbox and engine were connected with a geared drive. There was no clutch in this system. The Daimler-Benz A.W.20 used a planetary turning mechanism. Gears were switched with a special lever on the steering wheel. The gear shifter and turning mechanism operated with hydraulic assists that ran on oil.

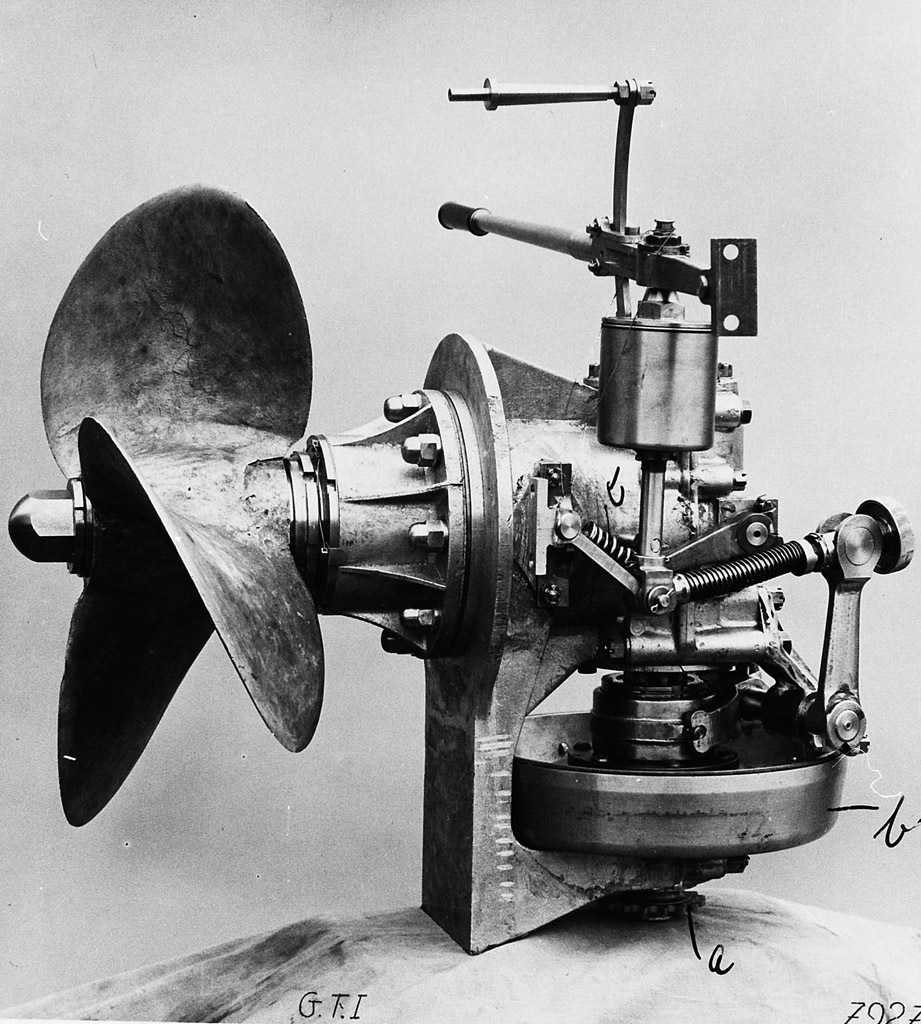

As you can see, the drivetrain was far from simple. The final drivers were also rather complex. They consisted of gears that connected to the drive sprockets externally. There was also a drive to two propellers that could be installed on the rear of the tank. The two propellers could turn to steer the tank in water.

The hull met the military's requirements. Since the tank was supposed to be amphibious, the lower front plate was raise high up. This was also a good solution when crossing obstacles. The driver, radio operator, and commander, who also operated the forward machine gun, sat in the front. A fighting compartment with a two man turret was behind it. There was also a one man machine gun turret in the back. Its crewman was not in the greatest conditions, as he was flanked by transmission elements.

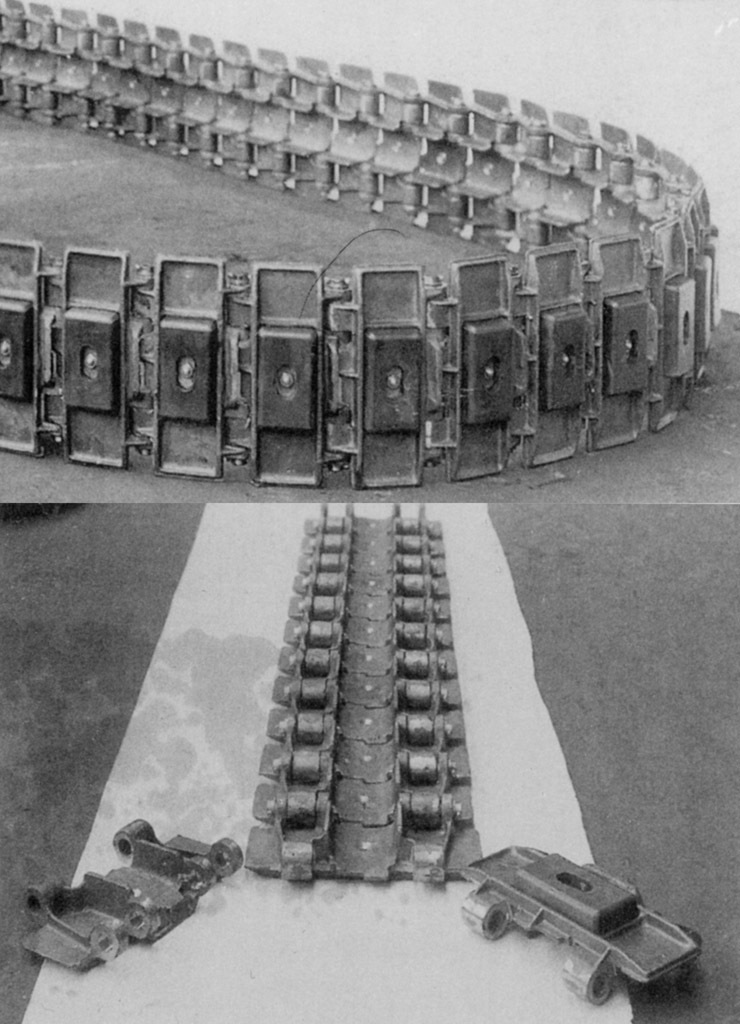

Unlike the drive train, the suspension was not very complicated. The drive sprocket and idler connected with the tracks by means of a pin-gear drive. They were covered by spaced armour from the outside. Each side had 16 small road wheels and 3 return rollers. The road wheels were grouped into bogeys with a leaf spring suspension. The 4 front wheels were installed at an angle to help climb obstacles. The suspension elements were covered with removable armour. The suspension was simple and easy to service. This tank used stamped tracks.

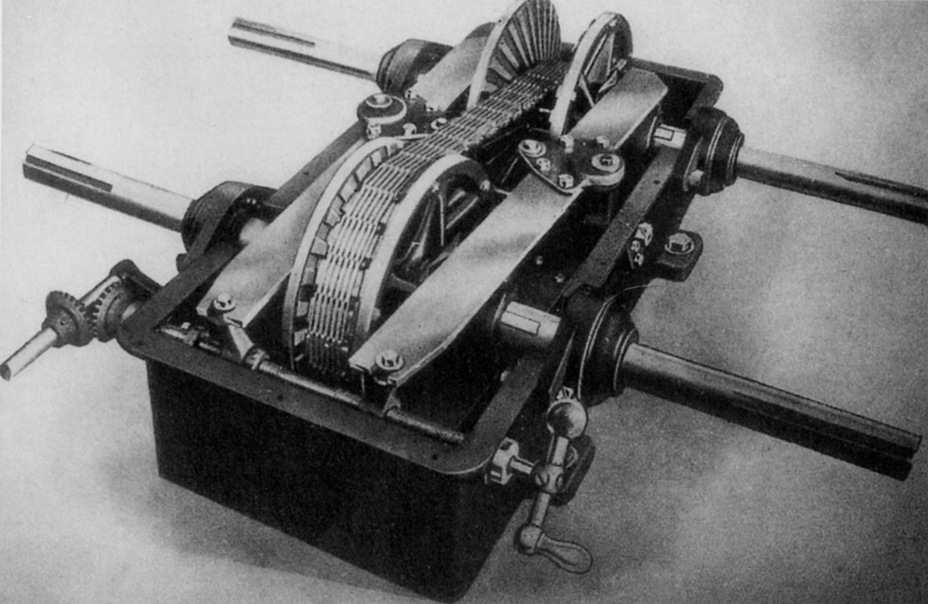

Krupp's chassis also used an aircraft engine: the 250 hp BMV Va. This 6-cylinder engine was smaller (22.9 L) and lighter (317 kg). This tank also had a complicated drive train. The massive 6-speed gearbox had a pneumatic drive. Unlike the Daimler-Benz design, it was placed to the right of the engine and was linked to it via a multi-disk clutch. The turning mechanism was also planetary, but it used hand operated band brakes.

The running gear was more complicated. Unlike the Daimler-Benz design, the drive sprocket used a lantern gear scheme. The track links were made from compressed rubber.

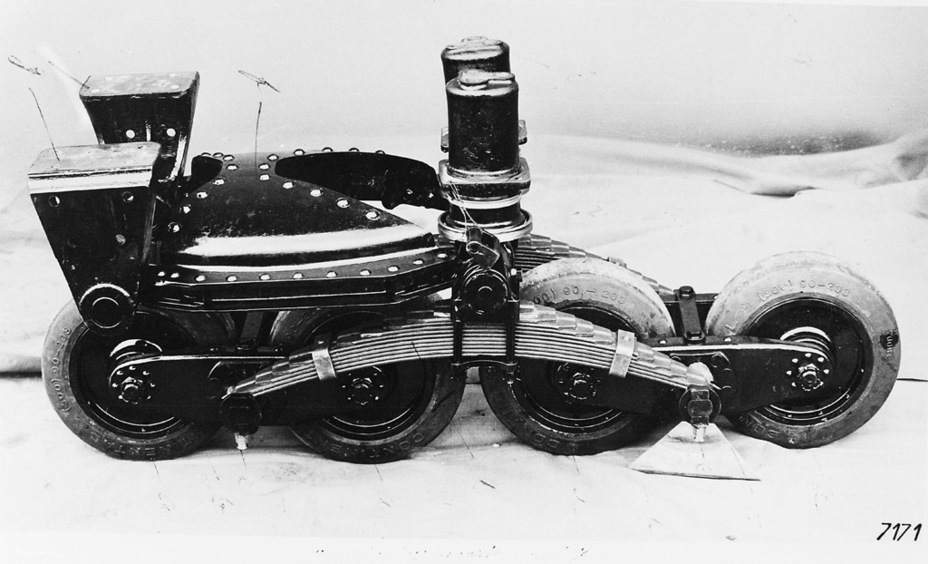

The suspension was also complex. Of the 17 road wheels, 12 were coupled into a strange system: bogies of two with coil springs. Three bogeys were connected in one assembly. Three additional road wheels were placed in the front to soften blows from obstacles. Two of them were also gathered into one bogey. One such wheel was also installed in the rear. Finally, a pair of rigidly mounted wheels was placed before the drive sprocket. The layout was functional, if bulky. The suspension was covered with bulletproof spaced armour.

Krupp designers changed both the gun and gun mount. A new mount allowed the turret roof bulge to be removed. The machine gun turret was also altered. Interestingly enough, only Krupp's tanks received the new turret. Daimler-Benz and Rheinmetall kept using the old designs for both turrets.

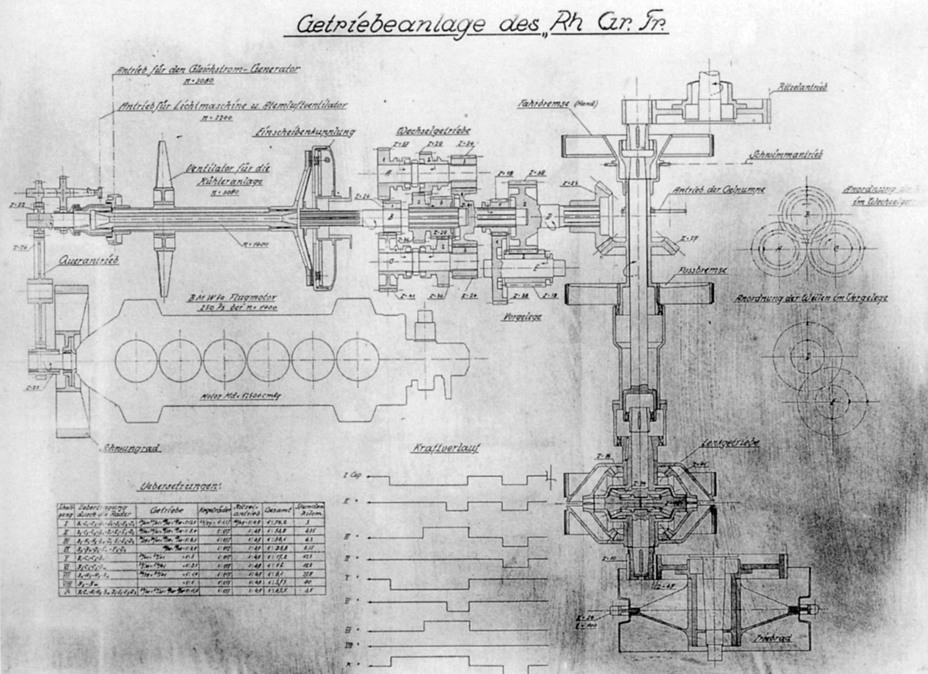

Like Krupp, Rheinmetall's engineers chose the BMW Va engine. The gearbox was also to the right of the engine, but the clutch only used one disc. The 8-speed gearbox had an electric drive. The double differential with a chain variator also looked interesting. This solution was very compact and not as complicated as that of its competitors.

The running gear of the Rheinmetall tank was also far from simple. The drive sprocket and idlers had pin gear schemes, but the teeth were in the middle of the sprockets. This tank used cast track links with rubber pads. 19 paired road wheels and 3 return rollers per side were used. 16 of the wheels were grouped into bogeys of 4 each. Each bogey had 2 rollers to not snag on the bottom of the tank. The bogeys had a hydraulic suspension, with each pair connected by hoses to the other pair. Two pairs of sprung road wheels were added to the front to reduce shock from obstacles, as well as one rigid pair in the back. This was a complex but compact solution, which allowed the inside of the hull to be used more rationally. Evacuation hatches could also be added to the sides of the tank.

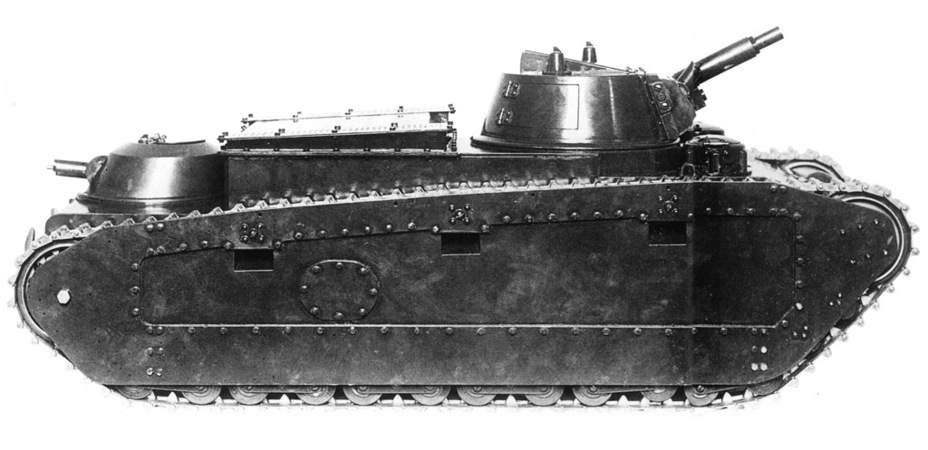

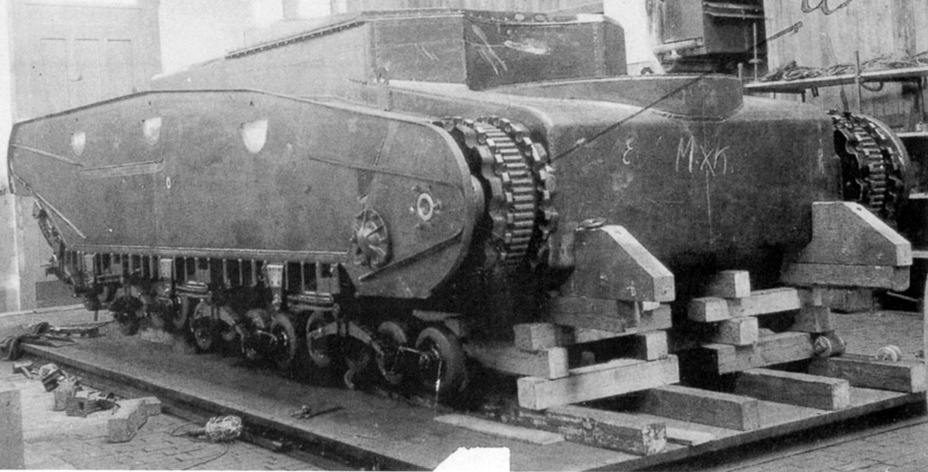

Assembly of the A.W.20 began in January of 1928 at the Rheinmetall factory in Unterluss. Assembly went on in strict secrecy. A new name was used for the vehicle starting in April of 1928: Grosstraktor (large tractor). They were occasionally referred to as excavator chassis to explain the presence of a turret ring. The indexed Grosstraktor I, Grosstraktor II, and Grosstraktor III that are present in some publications were never used in reality. The variants were usually referred to as Gr.Tr.Db, Gr.Tr.Kp, and Gr.Tr.Rh. Daimler-Benz tanks received the numbers 41 and 42, Krupp — 43 and 44, Rheinmetall — 45 and 46. Assembly was completed in the summer of 1929. The tanks had a long road east ahead of them.

Unequal trade

Debate on what happened next is common. There is a common claim that «the German sword was forged in the east». Allegedly, the USSR helped Germany develop its weapons. In reality, the offer to let Germany test its tanks away from prying eyes helped the USSR first and foremost. Cooperation with Germany on military affairs gave it access to most modern technologies of the time practically for free. It was rather the Soviet sword that was forged on a German anvil, but let's start at the beginning.

Military cooperation between the USSR and Germany began in 1924. The issue of offering Germany a proving grounds for testing of vehicles was raised in 1926. An agreement to organize a tank school was signed on December 3rd, 1926, in Moscow. Germany was liable for most of the costs. Even though the objective of the school was to teach German tankers, Soviet tankers were also included among its students, many of which were, by pure coincidence, engineers and designers. The school was called TEKO (Technical Courses of OSOAVIAKhIM) as of August 1928, but the Germans called the proving grounds at Kazan «Kama».

All six «large tractors» (Russian correspondence called them B.tr) arrived at TEKO in September of 1929. All tanks aside from Gr.Tr.Rh 46 had no turret. The poor quality of the German tanks can be seen from the amount of driving they partook in from then until the end of the year: Daimler-Benz tanks did not drive at all, Krupp tanks travelled for 3 and 60 km, Rheinmetall's tanks for 52 and 81 km. It was apparent almost immediately that the tanks need a huge amount of changes.

As the driving data shows, the Daimler-Benz tanks had the most issues. They had problems with their tracks, which slipped off easily. The problem was not entirely caused by the tracks, but also by the drive sprockets and idlers. There were also serious issues with engine cooling.

Krupp's tanks had their own problems. The air compressor was too small, which resulted in problems with both the gearbox and starter (both Krupp and Rheinmetall used pneumatic starters). This tank also had cooling issues.

The Gr.Tr.Rh proved to be the most reliable, but it had its own troubles. The use of a variator proved to be a poor idea, and the testers came to the conclusion that the turning mechanism had to be changed. The pneumatic starter, which worked poorly in cold weather, also did not prove itself.

The height of the Rheinmetall tanks' failure was an attempt to cross a water hazard. Due to the driver's mistake, one of the tanks sank on October 30th while driving backwards. Rheinmetall engineer Kerres, who was responsible for the tanks, drowned with it. The tank was raised and returned for repairs. This was the first and last such experiment. It was clear that the tanks were ill suited for swimming even without the driver's mistake. Rheinmetall and Daimler-Benz tanks weighed 16 tons, Krupp's weighed 16.4. Even without its turrets the Gr.Tr.Rh sat too deep and was close to taking on water. The propellers were removed from all of the tanks, although there were discussions that pontoons should be installed to help with buoyancy.

The winter and spring of 1930 was a time for alterations. However, they did not help Daimler-Benz tanks much. New 380 mm wide tracks with rubber pads were installed. Trials showed that the new tracks do not work well either. This was especially true for the rubber pads that were quickly destroyed. The second problem was the lead springs, which suffered additional stress during turns. Overheating remained a problem, and only improved slightly at the end of 1930. Tank #41 only drove for 25 km that year, tank #42 did not drive at all. Outings were restricted to the proving grounds and resulted in a top speed of 8.1 kph.

Krupp's tanks also had problems. Tank #43 did not drive all, tank #44 only drove for 10 km, and that was also only on the proving grounds territory. However, it did achieve a speed of 22.5 kph. Trials showed that German tracks had many drawbacks. All of the tanks were prone to throwing them off. This all led to the front placement of the transmission, copied from the British Carden-Loyd tractor and used on the La.S German tank. The issue was not with just the placement of the transmission. One look at the Grosstraktor drive sprockets shows that the engagement with the track was poor. Also the track links on all tanks wore down far too quickly. However, the Rheinmetall tanks showed the best results: #45 (the one that drowned) did not drive at all, but #46 drove for 215 km. This was the only Grosstraktor that made it outside of the proving grounds. Its top speed was 22 kph.

The suspension was modernized. Now there were only 16 road wheels were side. There were also many complaints regarding the gearbox. Gears could only be changed while standing still. Serious changes to the transmission had to be made.

Trials in 1931 revealed the last place of the Grosstraktor program. It went to Daimler-Benz. It was clear that the transmission design is hopeless. Tank #41 drove for only 31 km and showed a speed of 13 kph. This was because the tank could only move in 1st and 3rd gear. There was an idea to use a gearbox from heavy trucks, but this was not done. Trials of Daimler-Benz tanks ended here.

The situation with Krupp's tanks was also complicated, but not as hopeless. In 1931 tank #43 travelled for 32.5 km and tank #44 for 39.1 km. They showed a top speed of 35 and 38 kph respectively. The issue with the pneumatic gearbox did not go away. There were also problems with the cooling system. Problems with the rubber-metallic track links continued. As an experiment the rubber pads were removed from every other track link, but this did not help. One of the Krupp tanks received a slightly altered suspension.

Rheinmetall's tanks were in the lead. They were a little bit slower than Krupp's tanks: tank #45 accelerated to 30 kph, tank #46 to 35.5 kph. However, tank #45 ran for 215 km and tank #46 ran for 181 km. Tank #46 remained the only one with a turret. However, there were nearly no firing trials. Rheinmetall tanks showed their advantages in reliability. The 5-speed ZF Aphon SFG 280 gearbox installed in one of the tanks was the most reliable. One of the tanks also received new all metal track links with pin bearings. They worked much better than the initial tracks. The suspension was also somewhat changed.

The fact that Rheinmetall's tanks were in the lead is confirmed by the fact that they were the only ones to be used in off-road trials. Tank #46 managed to cross a 3.14 m wide trench and climb a 29 degree incline.

Serious progress on Krupp tanks began only in 1932. Tank #43 underwent a whole series of changes. The tank received a ZF Aphon SFG 280 gearbox, since it was clear that the pneumatic drive was a dead end. The running gear was seriously altered. The tank received improved types of track links, the drive sprockets changed, and portions of the spaced armour were cut away to make them easier to access. The results were not hard to see: in 1932 tank #43 drove for 154 km, more than both Krupp tanks before this put together.

Rheinmetall engineers also did not sit in one place. Tank #46 underwent serious changes in 1932. The number of road wheels was reduced to 14, of them 12 were grouped into bogeys of 2 each. Coil springs replaced the pneumatic suspension. This running gear proved itself superior. In 1932 tank #45 drove for 230 km and tank #46 for 290 km. Just tank #45 drove more than all of its competitors put together.

The trials of the Grosstraktors ended by October 12th, 1932. Oswald Lutz, the man responsible for mechanization of the Reichwehr, made his choice in favour of the Rheinmetall design. However, the Grosstraktor was no longer satisfactory at all. The idea of an amphibious medium tank was rejected. As for the Grosstraktors themselves, they all returned to Germany in 1933. After Hitler came to power all work at TEKO ended.

The results of the trials at Kazan demonstrate the the German sword was hardly forged there. The German medium tanks were very unpolished. Not a single tank went through a full cycle of trials. None of them even received radios until they returned to Germany. Full scale trials of the armament were never held. The Mittele Traktor, or Nb.Fz. did not inherit nearly anything from these tanks.

The benefit to the Soviet side was much greater. 65 Soviet citizens were put through courses at TEKO, as well as two commanders that were sent to study in Berlin in 1931. 8 Soviet designers including S.A. Ginzburg managed to familiarize themselves with German tanks. Is it hard to see why the Soviet T-28 used the suspension from the Krupp Grosstraktor? The German coaxial machine gun mount was also borrowed by Soviet designers.

Some elements can also be seen on other Soviet tanks. For instance, the experimental T-35 had the same driver's hatches as the Grosstraktor. Periscopic sights and the electric turret traverse were also copied. The design of the welded hulls also had an effect on Soviet tank building.

Finally, the USSR built their own Grosstraktor. The development of the PT-1 amphibious tank followed the inspection of German tanks. Of course, the tank turned out radically different, but even the placement of the commander in the hull instead of the turret was taken from the Germans. The history of the PT-1 begins from the tactical-technical requirements for an amphibious medium tank composed in June of 1930. The initial requirements called for a 20 ton tank with a speed of 30 kph. The armament consisted of a 45 mm cannon (the same as on the T-24) and three machine guns along the turret perimeter. An AA machine gun was also planned. Of course, the requirements changed drastically after encountering Christie's tank, but many elements were preserved.

Work on the Grosstraktor continued in Germany until 1935. The Krupp tanks underwent the greatest changes, especially to the chassis. The tanks received turrets with armament, radios, and rail antennas. The Rheinmetall tanks were also modernized. Tank #45 retained its original running gear. These tanks took part in the first exercises held by the Wehrmacht in 1935, after which their career came to an end. The very unpolished tanks did not work even for training.

The last years of the tanks' life were spent as training models. Daimler-Benz tanks were the first to go, installed as static monuments. The others followed soon enough.

Translated by Peter Samsonov. Read more interesting tank articles on his blog Tank Archives.

Sources:

- Panzer Tracts No.4 Panzerkampfwagen IV, Thomas L. Jentz, Hilary Louis Doyle, Darlington Publication, 1997, ISBN 0-9648793-4-4;

- PzKpfw IV and its Variants 1935-1945. Book 2, Walter J. Spielberger, Thomas L. Jentz, Hilary Louis Doyle, Schiffer Publishing, 2011, ISBN 978-0-7643-3756-7;

- So lebten und arbeiteten wir 1929 bis 1933 in Kama, Klaus Müller, 1982;

- National Archives and Records Administration;

- Russian State Military Archive;

- Central State Archive of St. Petersburg;

- Author's photo archive.