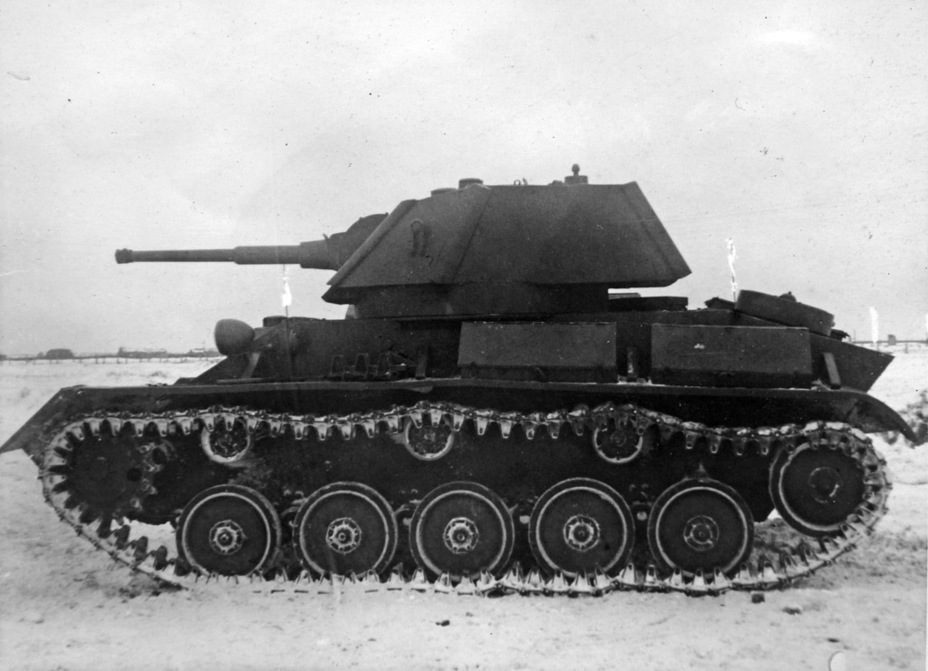

The T-70 light tank, developed as a continuation of the T-60, had a large number of drawbacks, especially compared to the T-50 that was supposed to become the Red Army's main tank according to pre-war plans. Nevertheless, the T-70 evolved in two directions. A small modernization led to the T-70B. A more thorough modernization led to the T-80, the last Soviet wartime light tank that was put into mass production.

Return of the two-man turret

The opinion that the task of a two-man turret for the T-70 tank was given to Astrov during its development is false. The desired list of improvements composed after the trials of the experimental GAZ-70 does not mention a two man turret. It is not even mentioned in the State Committee of Defense decree #1394 «On organization of production of the T-70 tank at the Molotov factory in Gorkiy». Specialists considered the conditions in the turret to be normal, and there were not even any plans for the development of a two-man turret.

The situation changed only in the summer of 1942, when the T-70 went into battle. Reports from the Bryansk and Central Fronts triggered the start of work to modernize the tank further. As for the turret, the trigger for a development of a two-man variant was a letter from the commander of the 1st Guards Tank Brigade, colonel N.D. Chunikhin.

«It is difficult for the commander to observe the battlefield, load the cannon and machine gun, and also fire. The company commander's job is even more complicated, since in addition to all this he has to command the company.

It is necessary to widen the turret for two crewmen."

A meeting was held on July 15th, 1942, to determine the improvements of the tank's design. Management from the People's Commissariat of Medium Machinebuilding, representatives of the GAZ, and representatives of from the GABTU were in attendance. The two-man turret was the fourth and last item on the list. According to meeting minutes a model of the turret would be prepared by August 1st. A gun would be tested by August 5th to determine the possibilities of fitting a 45 mm gun into such a turret.

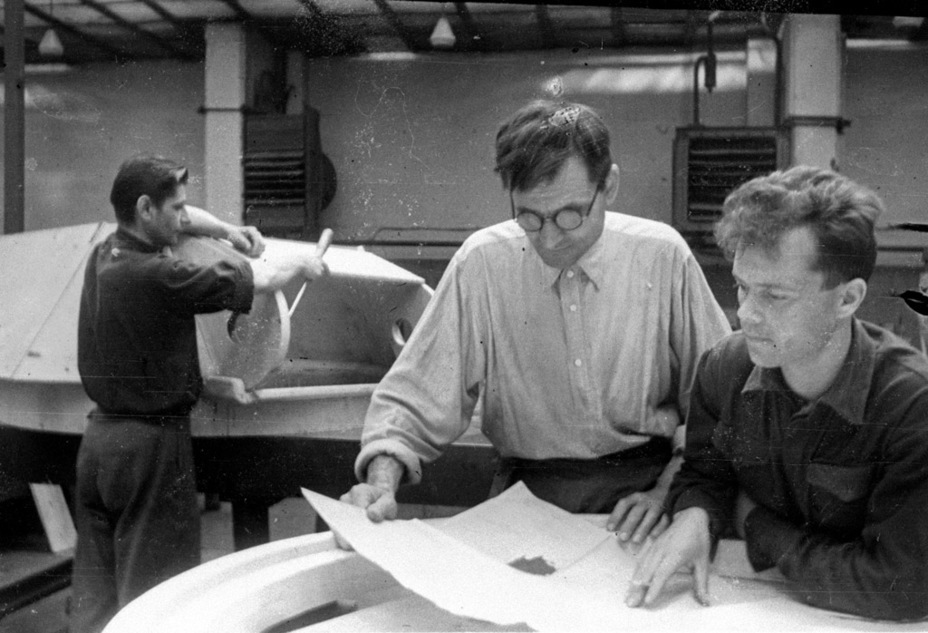

A wooden model of the two-man turret was built at the factory's design bureau. The work was very low priority, as the modernization of the running gear was more important. Work on the turret and a modernized GAZ-203 engine was only expedited after GKO decree #2276ss «On T-70 tanks» was published on September 8th. Item #4 called for the production of a tank with a two-man turret by October 1st. The supercharged engine was also expected by then.

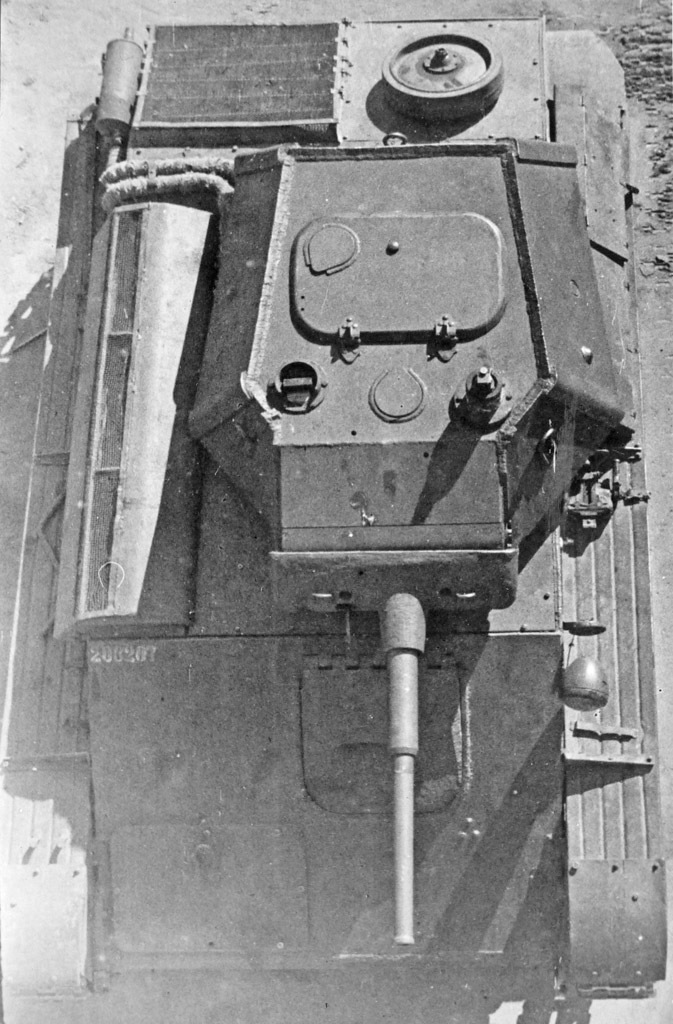

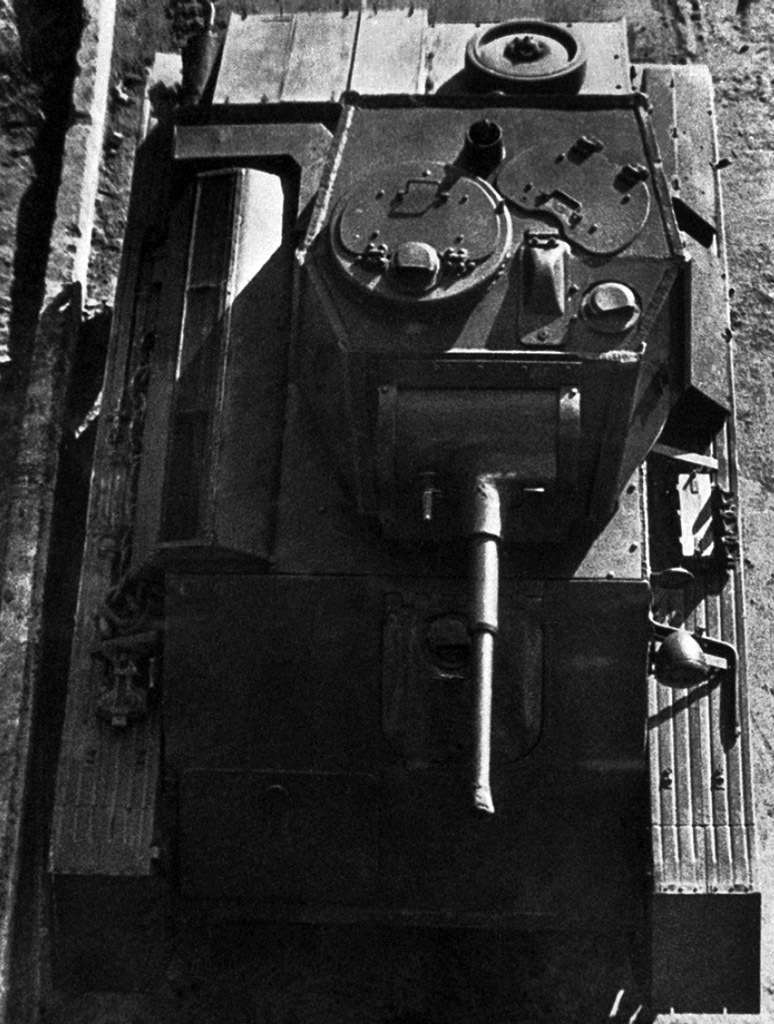

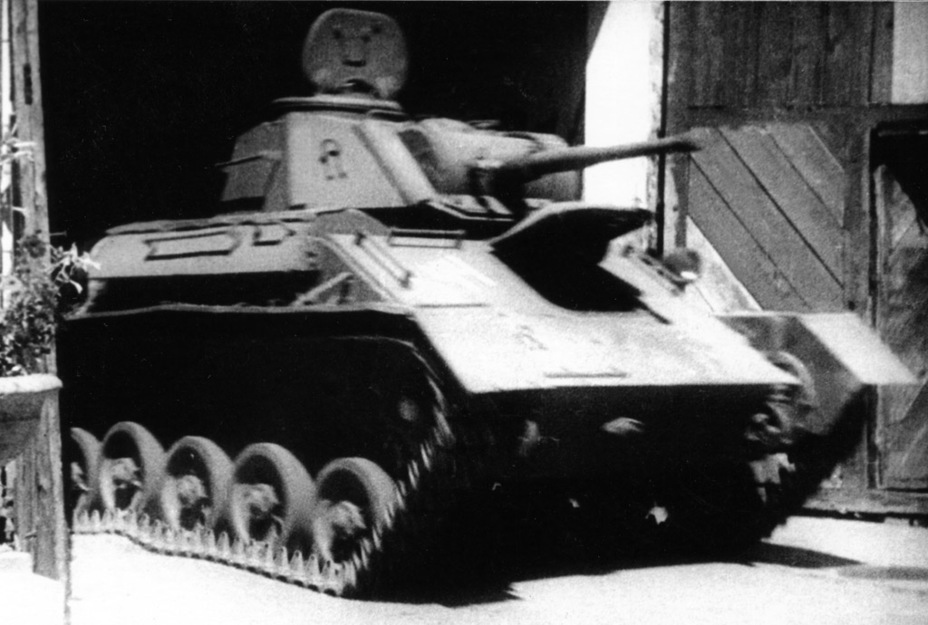

The new tank was not built from scratch. A T-70 tank with serial number 208207, produced in August of 1942, was taken to be modified. This was an experimental tank that was used to test the improved running gear and side armour. The sides were 25 mm thick instead of 15 mm. Changes to the chassis were minimal. Since the turret ring increased from 966 mm to 1112 mm in diameter, the fighting compartment roof had to be changed. Earlier, the plate was composed of two parts, allowing one to remove the engine without touching the turret. Now first the turret had to be removed, then the roof.

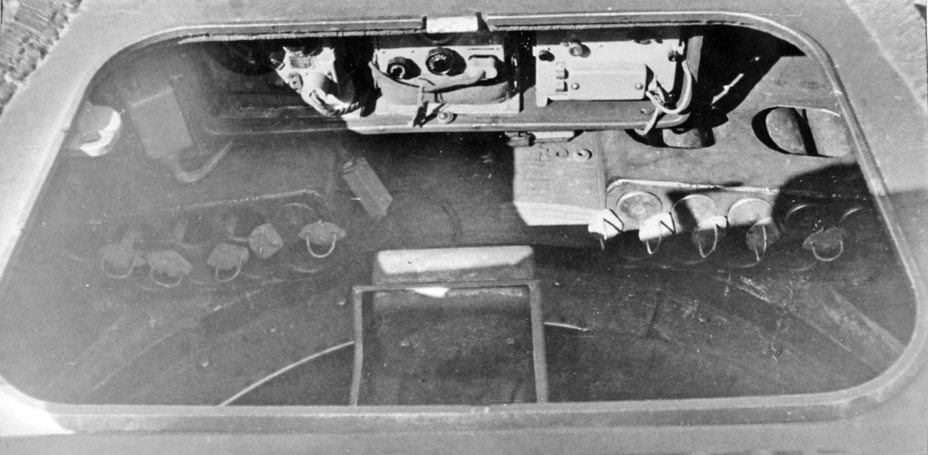

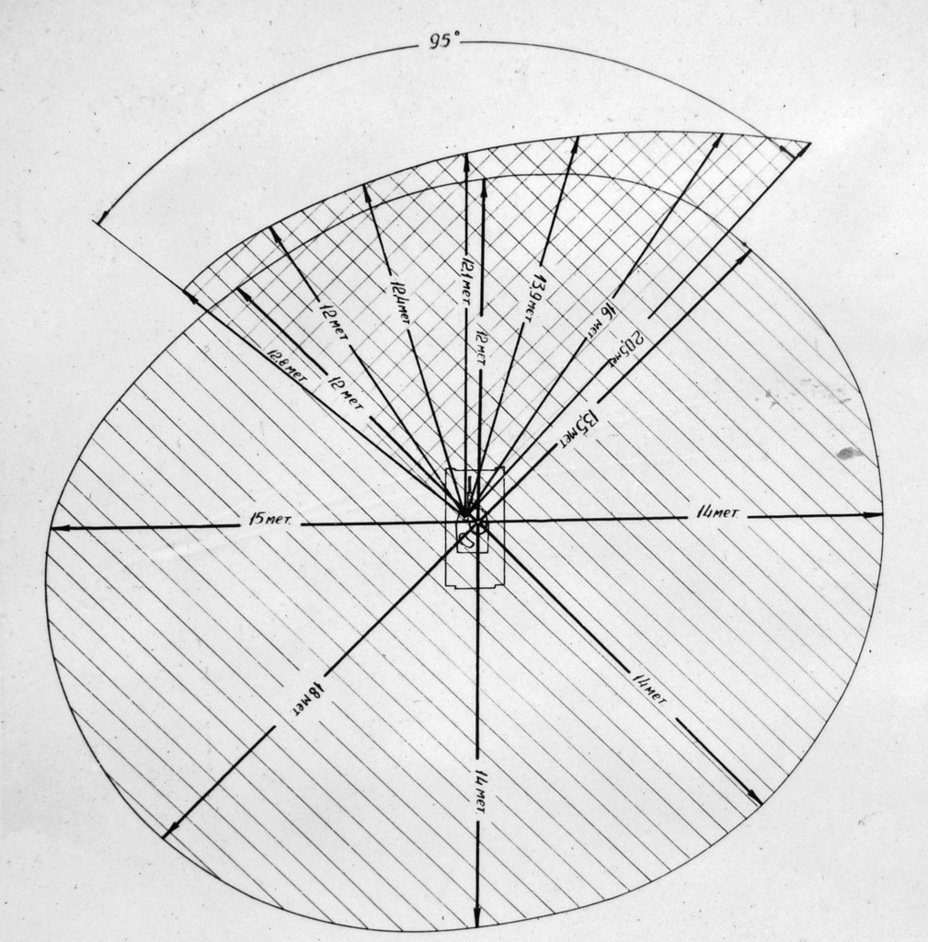

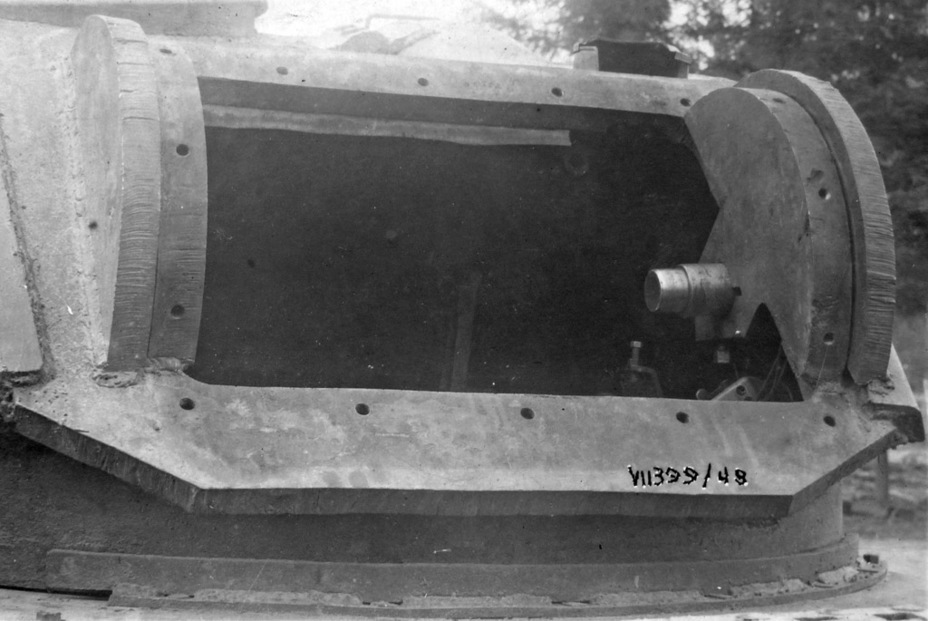

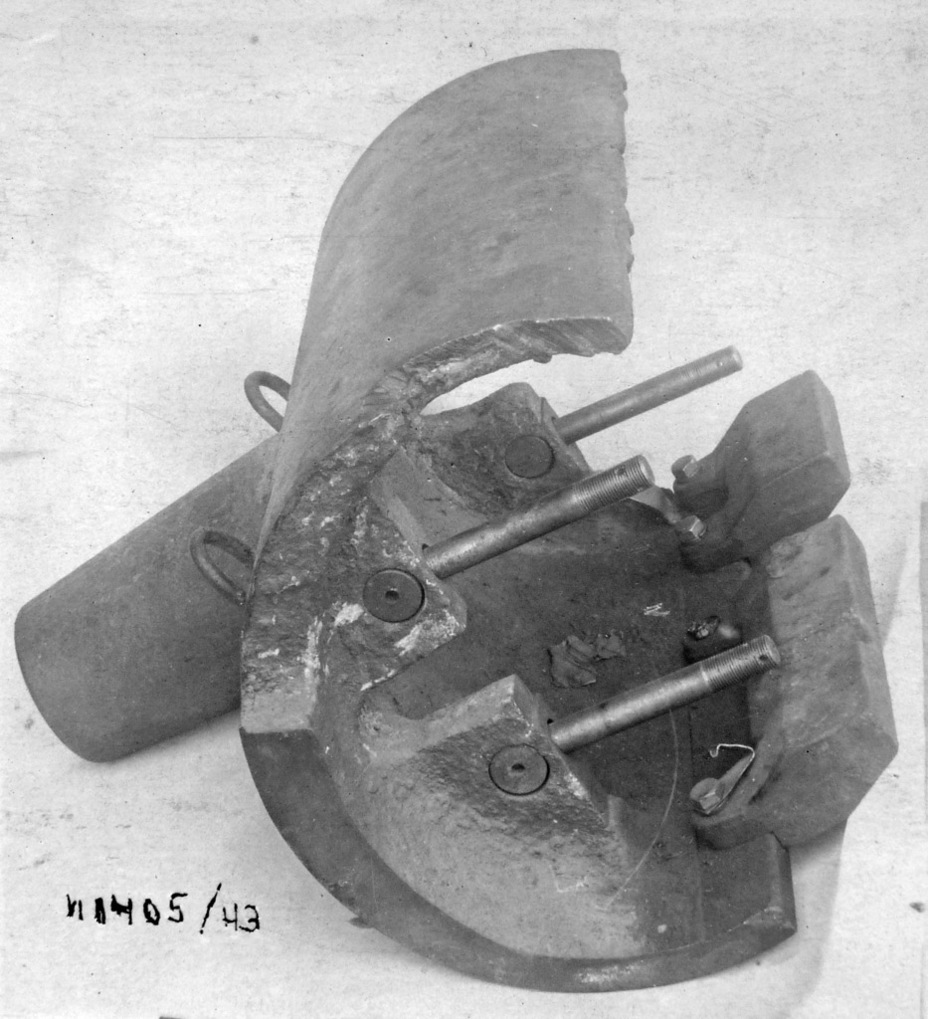

The design bureau with V.A. Dedkov at the helm took the stock T-70 turret as the starting point. Since the turret became much wider, all elements had to be changed, including the mantlet. A large turret bustle was added. It could fit not just a radio station, but two ammunition racks of 10 rounds each. However, the hatch turned out to be quite heavy, similar to the T-34's hatch on early tanks. The commander lost his 360 degree observation device that was installed in the hull before. Instead, the commander received the PTK periscope and the loader received a periscope analogous to the one used in the T-70's turret hatch before. The turret received a turntable, which made the crew's work easier.

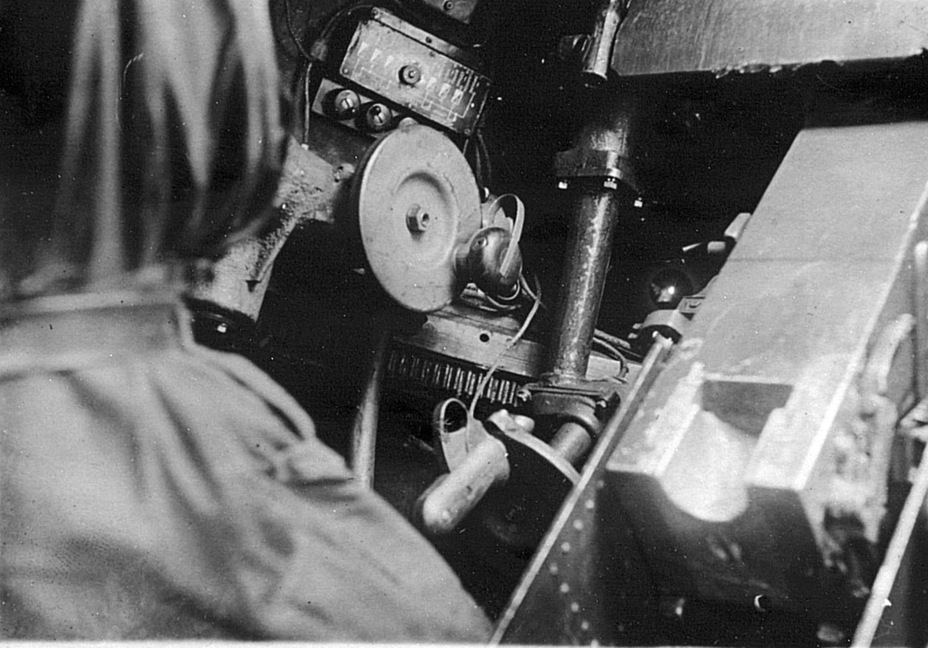

The conversion of the T-70 to use a two-man turret was finished closer to the end of September 1942. Factory trials began on September 27th. Trials continued until October 2nd. Their goal was to determine the rate of fire of the gun and working conditions in the two-man turret. To make the trials more representative, they were performed by four crews. Each one first shot with a two-man turret, then with a one-man turret. The rate of fire in the two-man turret was 8-9 RPM, the rate of fire in the one-man turret never surpassed 4-5 RPM. The hit rate increased from 47.5 to 71%. The gunner could fire without being distracted by observation of the battlefield, since the loader also had a periscope.

There were, however, some drawbacks. The seat mounts blocked some ammunition racks at certain traverse angles. At some angles the rate of fire was reduced to 5 RPM. The left 10-round rack could only be used for storage, as it was inaccessible to the loader. The ammunition fell out of the rack several times. The situation with the T-34's turret hatch repeated itself: the hatch was too heavy. In addition, the loader hit his head on the handle of the signal hatch and the main hatch's travel lock. The trigger mechanism pedal was inconveniently placed.

More than a dozen various defects were discovered. The turret had to be significantly improved. However, the idea of a two-man turret was deemed correct. The tank, named T-80 in the report, was recommended for acceptance into service after its drawbacks were corrected.

Improvements

Work on the improvement of the two-man turret coincided with an interest in SPAAGs. It was linked to the increase in activity of German assault aviation, as well as a captured report on the effectiveness of the Henschel Hs 129 airplane. SPAAGs armed with either the 12.7 mm DShK machine gun or 37 mm cannon were considered high priority.

An alternative cropped up in the fall of 1942. M3 medium tanks began to enter Soviet service in May of 1942. The 37 mm gun in their turret had a high angle of elevation, which allowed it to fire at airborne targets. High elevation angles were also useful in city fighting. It was not surprising that an idea was raised to equip the new tank with a high elevation gun mount. Interestingly enough, the same ideas came to the designers 5 years prior, that time as a result of experience in Spain.

Work on redoing the turret began in late October of 1942. Since the idea with one hatch turned out poor, a decision was made to make separate hatches for the gunner/commander and the loader. The loader received not a simple hatch, but a commander's cupola with at rotating periscope. The top part of the cupola rotated, which gave the loader 360 degree vision. The commander received a similar device instead of his PTK. The turret bustle remained, but its contents were altered. The overall design of the turret was also somewhat changed along with the hatches. The design of the seats and turntable changed to correct defects discovered in trials.

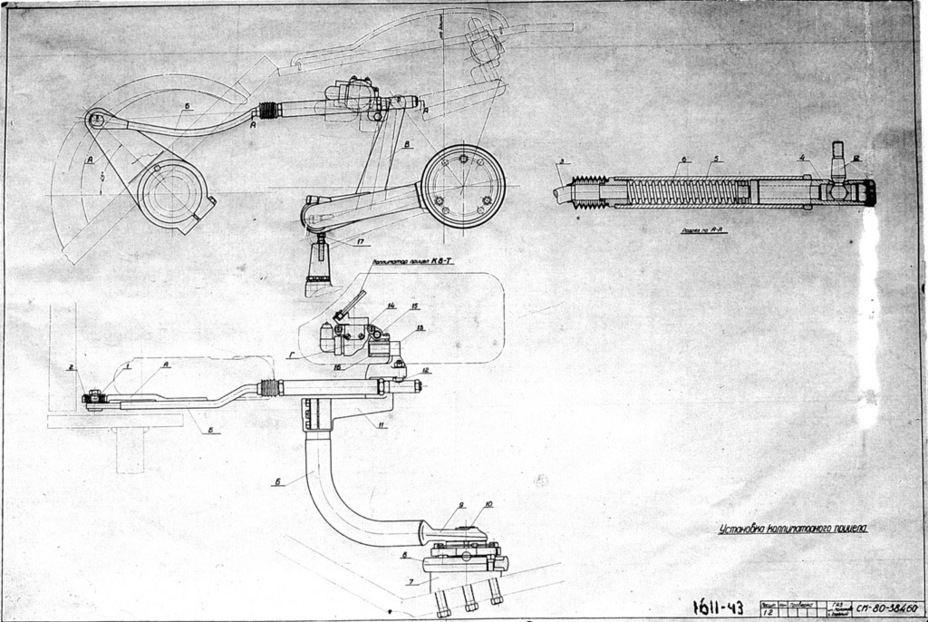

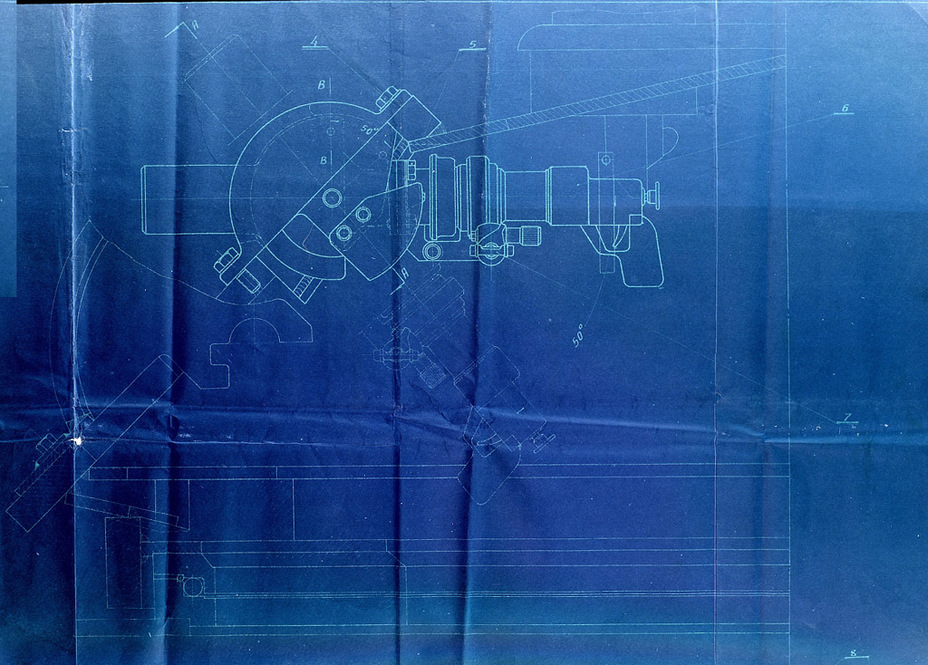

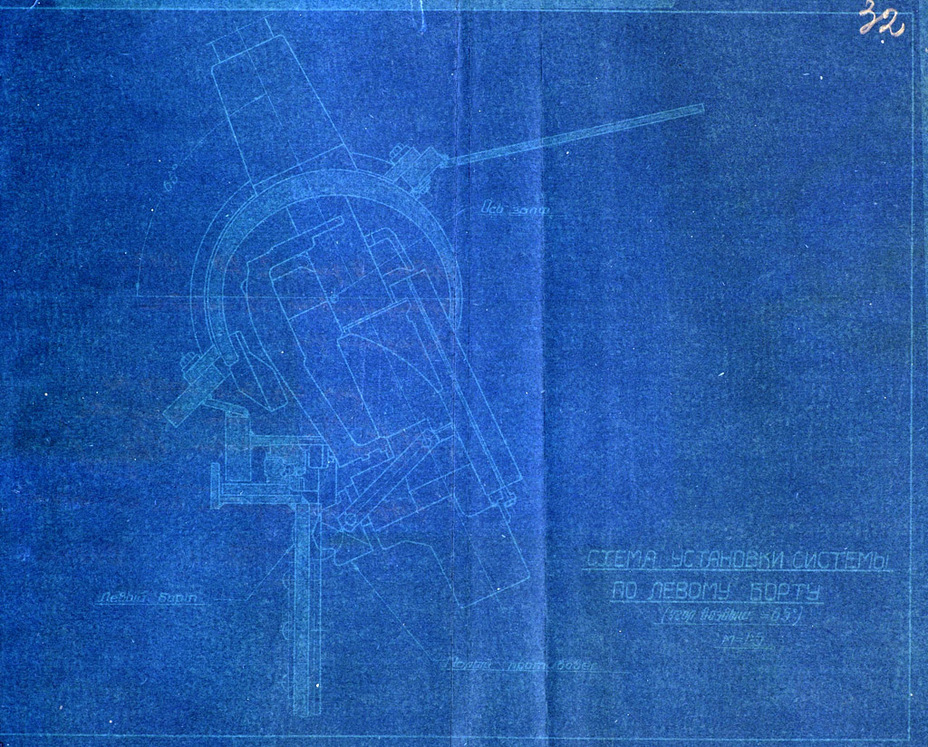

The front part of the turret and the gun mount changed. A new gun mount was introduced to allow for high gun elevation. The gun elevation in the new turret was up to 60 degrees. Since the existing sight was ill-adapted for firing at aircraft, a collimating K-8T sight was added to the telescopic sight. A separate hatch was added to the top of the turret that could be opened when firing at airborne targets. The GAZ-80, as it was called at the GAZ factory, was not a SPAAG, but it could be used to combat aircraft. The stock telescopic sight was also changed. A shorter variant was developed, indexed TP-80.

A mass production T-70B produced in October of 1942, previously used for various trials, was chosen to build the prototype. The chassis received a new fighting compartment roof. The tank's mass reached 11.2 tons, making the supercharged GAZ-203 engine a necessity. The compression ratio increased from 5.6:1 to 6.5:1, improving the power of each engine from 70 to 85 hp. The total power of the power plant, indexed M-80 or just «80», was 170 hp.

Work on the second T-80 prototype began by early December of 1942. The tank went through factory trials, driving for 55 km. The tank was then transferred to the NIBT proving grounds in Kubinka. A crew from the 223rd Tank Regiment, which already had experience with the T-70 tank, as well as two crews from the 30th Guards Tank Regiment which used the KV-1S tank, were present for the trials. The GAZ factory was represented by N.A. Astrov, the chief designer of the T-80. The tank fired both on the move and at standstill. The crew from the 223rd regiment first made 10 shots from the T-80, then from the T-70.

10 shots from the T-80 were made in 2 minutes 45 seconds, making 6 hits. The same 10 shots were fired from a T-70 in 4:42, and the number of hits was reduced to 3. During firing from short stops both tanks made 10 shots in 4:15, but the T-80 made 3 hits, while the T-70 made 4. This was the tank's only victory, and it lost significantly in all other trials.

The crews from the 30th Guards Tank Regiment made an even better showing. The second crew made 10 shots in 1:20 and scored 10 hits. The same 10 shots from short stops were made in 2:17 with 7 hits.

The crews also fired upwards to test the effect on aircraft. The first crew made 10 shots in 31 seconds, the second — in 37. On one hand, a fully fledged SPAAG would have a rate of fire that was several times higher. On the other hand, concentrated fire from several tanks would introduce problems for attacking aircraft.

Mobility trials were also performed. The T-80 drove for 215 km in total, of which 42 were on a highway, 60 on dirt roads, and 93 on forest roads. The average speed on a dirt road was 23.8 kph with a fuel expenditure of 167 L per 100 km. In difficult conditions the speed decreased to 12.1 kph and the fuel expenditure increased to 184 L per 100 km. The tank performed at the same level as the T-70 on grades. Testers spoke highly of the tank's observation devices.

Trials were finished by December 9th. The results were obvious. The commission deemed the difficulty of access to the engines and a lack of interchangeable parts, but the T-80 was superior to the T-70B in everything else. Stalin was informed of the results of the trials on December 18th. On December 27th, 1942, he signed GKO decree #2661s «On organization of production of the T-80 tank at the former Mytishi rail car factory». According to this document, 25 tanks of this type were due in April of 1943, 50 in May, 100 in June. The GAZ supplied factory #40, formerly factory #592, with technical documentation, engines, and a number of other assemblies and components.

The design bureau began improvements of technical documentation starting in the middle of December 1942. The turret was changed once again, this time much less noticeably. The position of the commander/gunner's hatch changed. The turret roof became slanted. This change was due to poor balance of the original turret.

What happened next was the most interesting part of the story. Even though the GAZ did not officially produce the T-80, a post-war summary report indicates that 4 tanks of this type were produced in Gorkiy. Other sources indicate that 5 tanks were built at the GAZ.

Even though production of the T-80 at the Molotov GAZ factory was not planned, in practice preparations for production were underway by January of 1943 by the initiative of the NKSM. The first pilot T-80 was built in early March. A hull and turret produced at factory #176 were used. This factory was also the supplier of hulls and turrets for factory #40, and the tanks from the two factories were not significantly different. This is also true for the driver's hatch: the prototype had a cast one, and the pilot had a stamped one.

Trials of the first production T-80 showed problems. The elevation mechanism linkage mount broke after the 11th shot. Work on correcting the issue began. Meanwhile, 2 more tanks were completed by March 11th, 6 more were in the process of being assembled. 8 more T-80s were completed by the end of the month, although only 7 were fully equipped. 9 more tanks were started and awaited assembly.

These tanks did not appear in the GAZ's monthly reports because they were never officially accepted. In monthly reports senior military representative Okunev wrote that the tanks could only be accepted conditionally due to issues when firing at high elevations.

Design improvements continued in parallel with the production. For instance, maintenance hatches were added in the floor that allowed taking off the engine sump without removing the engine. The factory design bureau also designed a welded gun shield. Many modernizations were never put into production. Work on the T-80 at the GAZ began to die in April.

Tanks with defective guns languished at the factory until their hour finally came. As they were not accepted for service, the factory could not even send them to a training unit. The solution was to limit the elevation to 25 degrees. The GBTU approved this move with the caveat that these tanks can only be sent to training units. However, only 2 tanks were delivered. They were sent to the 1st Independent Training Tank Brigade. This happened in June 1943, when the GAZ was bombed. It's possible that the bombs destroyed all remaining tanks. This explains the number 4 in the GAZ's reports: 2 prototypes and 2 training tanks.

Based on the prototype in which the VT-43 gun was tested, the GAZ tanks had no turret handrails or exhaust system protection.

The last work of the factory's design bureau on the T-80 is dated May-June 1943. Later, in part due to the bombing of the factory, no further work was done. The factory had bigger concerns. The idea of improving the tank's armament, which was pitched by Astrov, was not in demand. He proposed to install a 76 mm regimental gun instead of a 45 mm gun. Another idea, which at least survived on paper, was the idea of installing a 50 mm breech-loaded S-11 mortar. It was developed at the TsAKB in the summer of 1943. The idea was copied from the British Valentine tank, but due to the T-80's cancellation it was never put into practice.

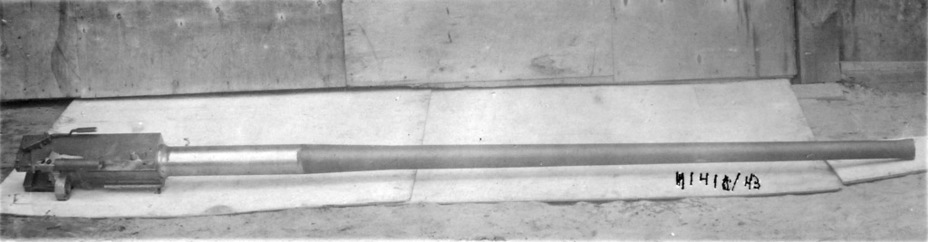

Factory trials of the 45 mm VT-42 gun installed in a T-70 tank were carried out in March of 1943. This gun had the ballistics of the model 1942 45 mm gun. A reasonable idea of installing this more powerful gun into the T-80 was voiced. It was installed in one of the tanks produced at the Molotov GAZ factory. Thanks to these reports, we can see what a production T-80 built at this factory looked like.

The topic of a tank gun with ballistics of the M-42 that could be used in the T-80 tank was included in the list of work at the OKB-172 and factory #235 back in late December of 1942. In addition, OKB-15 launched the «45 mm universal OKB-15 gun installation into the T-80 tank» project in January of 1943. This was the automatic NS-45 aircraft gun, a further development of the ZUT-37. Work did not progress past an order and draft designs.

A technical meeting attended by the chief designer of factory #235 Ye.A.Guglyants, as well as representatives of the OKB-172, GBTU, and deputy chief designer of factory #40 G.I. Kashtanov was held on May 27th. The VT-43 project was approved at this meeting. Plans were made to install the prototype into a T-80 tank by June 15th. The volume of trials would be reduced. Factory #235 was supposed to produce the first 10 guns to send to factory #40 for installation into production tanks after that. A group of designers from factory #235 would be sent to factory #40 in Mytishi to assist.

The plan accepted at the meeting was vastly different from what happened in real life. Factory #40 had no time for the VT-43, and the gun was installed in a GAZ production tank. Officially it was never delivered and it never existed in any documents. The installation of the VT-43 was easy, the only problem was that the tank arrived at the Gorohovets artillery proving grounds on September 2nd, 1943, when production of the T-80 was over and preparation for SU-15M production was underway. Nevertheless, trials began on September 27th and continued until October 15th. 850 shots were made from the new gun, 309 of which were supercharged, 319 were armour piercing with regular charge, 71 were APCR, and 151 were HE. The results showed that the precision and durability of the gun were satisfactory. There were some complaints about the semiautomatic mechanism. The recoil mechanisms, converted to accommodate the more powerful gun, worked well. There were no complaints about the aiming mechanism. Average rate of fire was 12-13 RPM.

Overall the system passed trials, but it was clearly too late. It is that much more interesting that more trials were performed in April of 1944. The ability to fire at airborne targets with the VT-43 was tested. Experiments showed that the T-80 was ineffective as a SPAAG. The very fact that these trials were held is confusing, since the results were predictable. Also, what sense was there in testing a tank that was removed from production in late August of 1943?

Cavalry tank from Mytishi

Organization of T-80 production at factory #40 was much more difficult than in Gorkiy. The task was much more difficult for the team at Mytishi. They already had experience in building the SG-122, but converting an existing chassis into an SPG is one thing, but building a tank from scratch is another. A new factory was built in place of the old one, which is no simple task. In addition, the deadlines specified in GKO decree #2661s were very tight. The factory had to deliver its first 25 tanks in April.

The factory was not left to fend for itself. Specialists from factories #183, #174, UZTM, and ChKZ were sent to consult. The factory #592 design bureau was reorganized into the factory #40 design bureau. A number of specialists, including Ye.V. Sinilshikov and S.G. Pererushev left to work at the TsAKB.

Nevertheless, the preparations were difficult. Instead of 500 workers that were promised in January and 2000 in February, only 214 arrived. There as a serious deficiency in designers: 58 out of 70 in the chief designer's department and 107 out of 254 in the technical bureau by March 1st. The first T-80 blueprints began to arrive in early March of 1943. By April 1st the factory only had 446 tools out of 550, only 352 were installed. While 3299 workers had arrived, 933 of them had to be refused as physically unsuitable for the work. Most of the remainder were untrained.

There were issues with components build by subcontractors. For instance, only 12 M-80 engines arrived from the Molotov GAZ in all of Q2 1943. A lack of engines was the greatest barrier for carrying out requirements of GKO decree #2661. Despite all the difficulties, assembly of the first T-80s began in Mytishi in April of 1943. Assembly was done in very nerve-wracking conditions, but 5 tanks were delivered by May 1st, of them 2 equipped with radios. 7 tanks were delivered by June 1st, and all produced tanks were retrofitted with radios. Then, production stopped for a month. 8 more tanks were assembled in June, but they were not accepted.

The senior military representative at factory #40, Engineer-Major Slyusarev, blamed the factory management, accusing it of idleness. He might have been partially correct. The organization of production indeed went slowly. However, one has to understand that it's impossible to build a tank factory from nothing in 3-4 months that could not only meet large quotas but keep up the quality of work. No other outcome was possible given a deficit of personnel and lack of tools.

Defects on tanks built in Mytishi were a common occurrence. 4 instances of broken final drives and 2 instances of broken main clutches were recorded from May to June of 1943. The gun mount was harshly criticized. In addition to defects with the recoil mechanism, analogous to those seen in Gorkiy, there were also assembly defects. For instance, the TMF sight, temporarily used instead of the TP-80 sight, had a maximum elevation of 50-53 degrees. All tanks built in April-May needed improvements. This was shown in trials of a May production T-80 at the NIBT proving grounds. Damage to final drive and main drive gears occurred after 370 km. This was the end of warranty trials.

The factory entered July with 22 tanks on hand. Only 3 new tanks were built in July, the rest were only refined. 11 of them were April-May production tanks that had to be seriously reworked. This fact led to a mistake in the calculation of the number of tanks built at factory #40. The first tanks were sent out in July: 6 T-80s for the Gorkiy training school, 5 more to Syzran. The Red Army did not feel confident sending the first T-80s to the front.

Mass production began in August, when 40 tanks were delivered. However, after the Battle of Kursk the GABTU came to the conclusion that production of T-70 and T-80 tanks is pointless. According to GKO decree #3964ss published on August 21st, 1943, production of the T-80 at factory #40 stopped as of September 1st. The factory would instead produce the SU-76 SPG. In total, 66 tanks were built at factory #40. Considering the 8 T-80s at the Molotov GAZ that were only partially accepted and 2 more experimental tanks, a total of 76 T-80s were built. Factory #176 managed to produce 334 sets of turrets and hulls. Despite some issues, the design was quite good. Its creators, including N.A. Astrov, were awarded the Stalin prize 2nd class in 1943. It was not their fault that the time of the light tank was at its end.

54 T-80s from the «main» production batch were split between two tank regiments. On August 27th, 1943, train #10/993 left Tula with 27 T-80s meant for the 54th Independent Tank Regiment. Another 27 tanks were sent to the 230th Tank Regiment by train #10/235. The crews had to battle with their own tanks at first. The quality of assembly was still low, which became apparent during training. Torsion bars burst, ball bearings fell out of the turret rings, defects in final drives were discovered.

Both regiments that used T-80 tanks fought alongside cavalry units. As of October 8th, 1943, the 230th Tank Regiment fought alongside the 2nd Guards Cavalry Division. Its first combat mission was the crossing of the Dnieper. When the regiment first saw battle it had 10 T-34s, 18 T-80s, and 1 T-70 available. On October 10th the regiment stormed Zatonsk. The 1st company under the command of Senior Lieutenant A.V. Oganesyan with 4 T-34s and 3 T-80s did exceptionally well. The tanks were not only used to support the cavalry, but to ferry them to the battlefield. On the 10th the regiment lost 1 T-80 burned up and 2 knocked out. On the next day the tanks went to rescue cavalrymen who were surrounded at Sychevka. Battles for Zatonsk continued on October 12th. 3 SPGs (likely Marders), 6 PzIII and PzIV, 2 APCs, 1 armoured car, and 3 trucks were destroyed. The Soviet losses totalled 3 burned T-80s ad 2 knocked out T-34s, 5 men killed and 10 wounded. The accompanying 7th Guards Cavalry Regiment had 7 killed and 30 wounded.

The fierce fighting for Zatonsk continued for several days. From October 10th to 20th the 230th Tank Regiment lost 20 men killed and 28 wounded. 1 tanker went MIA. By November 3rd 4 T-34s, 12 T-80s, and 1 T-70 remained.

On November 5th the regiment was ordered to support the cavalry in an attack on Rakovka and fortify it. Jointly with cavalry the tankers reached the region of Korostyeshev, Zhitomir oblast. The regiment lost 1 T-34 burned and 1 T-80 knocked out.

The regiment was in Zhitomir by the 14th. On the next day the Germans counterattacked. The regiment's commander, Lieutenant Colonel D.A. Sherbakov, was killed on that day (other sources say he was only heavily wounded and died on April 1st, 1945). In battles for Zhitomir the regiment lost 5 tanks, 8 men were killed, 10 wounded, 22 missing. Zhitomir was recaptured by the Germasn on November 19th and liberated again on December 31st. The 230th Tank Regiment was sent to be reformed.

The 54th Tank Regiment fought alongside the 12th Guards Cavalry Division. Like the 230th TR, it had 10 T-34 medium tanks. The regiment pursued the retreating enemy all October. The first real battle took place for the city of Poyarkin in Kherson oblast on October 29th, 1943. Here the regiment lost 5 T-34s and 2 T-80s, but destroyed 2 enemy SPGs and 2 tanks. The regiment still had 6 T-34s and 25 T-80s by January 1st, 1944. The unit fought like this in January-February of 1944.. Only 2 T-80s were lost due to enemy action, the rest broke down. The regiment received 20 Valentine IXs on April 22nd.

Repair factory #8 was tasked with repairs of the T-80 tank. As of the spring of 1944 it was located in Kiev. 4 tanks were repaired in July of 1944, 12 in August. The last use of these tanks in battle took place in the summer of 1944, they again fought in tank regiments attached to cavalry divisions. For instance, the 61st Tank Regiment had 4 T-80s, the 58th Tank Regiment had two. After the Lvov-Sandomierz offensive the tanks were designated for training only. As of 1946 around 20 of them were preserved at the Kharkov tank school. None of them survived, but one T-80 was preserved at the Kubinka Tank Museum and can be seen on display.

Translated by Peter Samsonov. Read more interesting tank articles on his blog Tank Archives.

Sources:

- Russian State Archive of Economics

- Central Archives of the Russian Ministry of Defence

- Russian State Archive of Socio-Political History

- Russian State Archive of Film and Photo Documents

- Author's archive